KWIK DRAW UNIPHOS

Airtester HP (Multiport Sampling)

for compressed air according to EN 12021

Instruction for use

1. Use

The compressed air monitoring set “KWIK DRAW

UNIPHOS Airtester HP” (HP = high pressure) is used

to determine the content of carbon monoxide, carbon

dioxide, oil and water vapour in respirable air from

compressors and compressed gas cylinders. .

According to EN Standard 12021 air for respiratory

equipment must meet the following quality

requirements:

CO content max. 15 ppm

CO content max. 500 ppm

2

Free of odor and taste, i.e. practically free of

critical mineral oil content (from experience the oil

content is less than 0.5 mg/m³)

Water content in compressed air cylinders:

max. 50 mg/m³ at a charging pressure of 200 bar

max. 35 mg/m³ at a charging pressure of 300 bar

max. 25 mg/m³ of the air from the compressor

-

-

-

-

The requirements concerning the maximum water

vapour content refer to the type of equipment used

(200 or 300 bar) and, therefore, apply also to each

pressure level of the compressed gas cylinders

below the maximum values given above. .

All maximum values are based on air not under

pressure.

2. Measuring Principle

3. Design

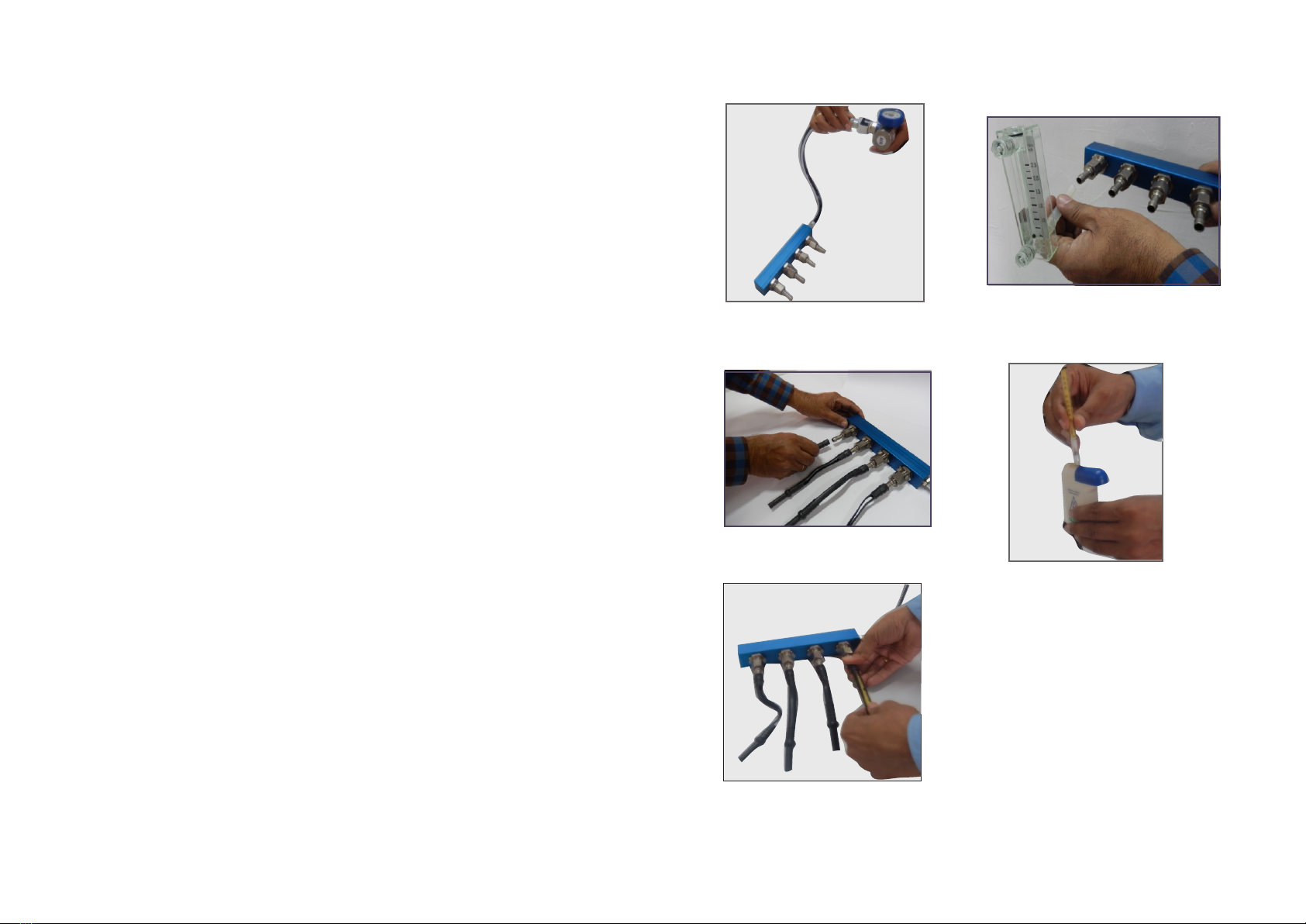

The case contents all parts required for measuring

(see fig. 1):

-

The standard case contents one package of each of

- 3 -

Fig. 1 KWIKDRAW UNIPHOS Airtester HP

4. Technical Data

Measuring ranges of the Detector Tubes:

Carbon monoxide detector tubes

5 to 70 ppm carbon monoxide at a flow rate of

0.3 l/min in a measuring time of 5 minutes. (required

sampling volume 1.5 l).

See also specific instructions for use of the KWIK

DRAW / MSA AUER detector tubes CO-HP.

Carbon dioxide detector tubes

100 to 2000 ppm carbon dioxide at a flow rate of

0.3 l/min in a measuring time of 5 minutes. (required

sampling volume 1.5 l).

See also specific instructions for use of the

KWIK DRAW / MSA AUER detector tubes CO2-HP.

Oil detector tubes

This type of tube indicates semi-quantitatively mineral

and synthetic Oils.

Check for oil contents (vapor + mist) at a flow rate of

2.5 l/min in a measuring time of 24 minutes. (required

sampling volume 60 l). The content of oil is determined

as per the instruction given to use the KWIK

DRAW / MSA detector tube Oil-HP Synth.

the four types detector tubes. In addition, the case

has space for storing four additional spare

packages.

air

300 + 30 bar

0.3 , 1.0 and 2.5 l/min.

(The detector tubes are to be

fitted in an appropriate port of

manifold to pass required

sample air.)

5 kg

h= 120; w= 320; l= 420 mm

Operation medium:

Maximum pressure:

Flow:

Weight (with case):

Dimensions:

- 6 -

6. Maintenance

6.1 General

In view of the significance of the accuracy of

measuring results, the test device must be treated

with care. Dirt must be avoided at all time, especially

at the high-pressure connection.

Flushing and cleaning of the test device must be

made as described in para. 5.2. After measuring is

completed, the test device shell is stored in the case.

The high pressure connection should be closed with

a protective cap.

Function checks should be made at regular intervals

and if erroneous measurements are suspected.

6.2 Disorders

If the hand wheel of the test device cannot be

loosened while it is connected to a compressed gas

cylinder or compressor, check if connection is under

pressure. In this case close the cylinder valve or

compressor valve and release air from test device.

Leaks at the connection to the cylinder or

compressor could be due to a defect gasket. In this

case replace the gasket.

If the high pressure gauge or the detector tube holder

is defective, they must be replaced.

In case of other disorders the device should be

returned for repair to UNIPHOS or any authorized

service station.

7. Part Numbers

KWIK DRAW UNIPHOS Airtester HP

(Compressed air monitoring set)

Complete with case containing:

Test device consisting of pressure reducer with

high pressure gauge, manifold, flow meter detector

tube holder.

Adapter for 200 and 300 bar one each for connecting

to compressor charging panel

Timer

Device for breaking off detector tube tips,

Detector tubes for measuring carbon monoxide,

carbon dioxide, water vapor, oil - one package each.

Accessories and Spare Parts

Detector tubes CO-HP*

Detector tubes CO -HP*

2

Detector tubes H O-HP*

2

* = Package of 10 pieces

D5085847

D5085848

D5085849

Detector tubes Oil- HP Synth.*

for testing of mineral and synthetic Oil

Pressure reducer with pressure gauge

Manifold

Gaskets-lifter

Detector tube holder

Timer

Tube tip breaking device

Case

Case insert

Flow meter

10040887

D4074937

CR001444

D4060241

D4074058

D5185020

D5085012

D5185911

D5185931

CR001452

The pressure in the compressed gas cylinders, or

in the compressor charging panel is reduced by a

pressure reducer. The air to be sampled is taken

continuously via a regulatory valve in the manifold.

There are four outlets for this manifold which release

fixed flow rate of gas. The flow rate of each port is

printed on the body of the manifold, viz 0.3 l/min,

0.3 l/min 1.0 l/min and 2.5 l/min. The air coming out

from these ports is taken through detector tube for a

specific time. The length of stain in the detector tube

is an index of the concentration of the measured

substance. This can be read directly from the detector

tube scale.

The test device, consisting of pressure reducer,

Pressure gauge, manifold, flow meter, detector

tube holder, adapter for connection to a

compressor charging panel ( for charging

connection 300 or 200 bar), timer, detector tube

tip breaker, tubes (package of 10) for measuring

CO, CO2, water vapor and oil content (sum of

Oil vapor and mist). .