WideFormat March 8, 2009

Océ Arizona 350 GT Printer

www.bertl.com

Copyright © 2008 BERTL, Inc. March 8, 2009

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronically through the www.BERTL.com Web site and may not be stored in electronic or hard copy format. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsibility for any inaccuracies or omissions contained in this document. Page 6

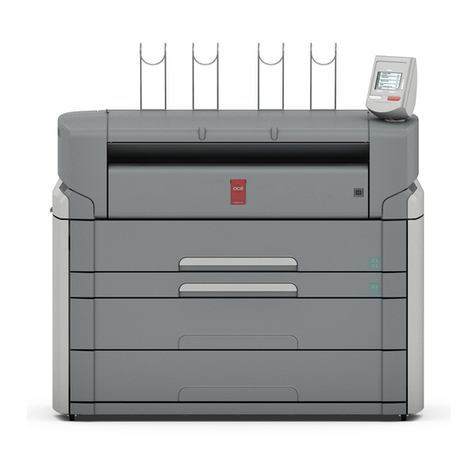

THE OCÉ ARIZONA 350 GT PRINTER

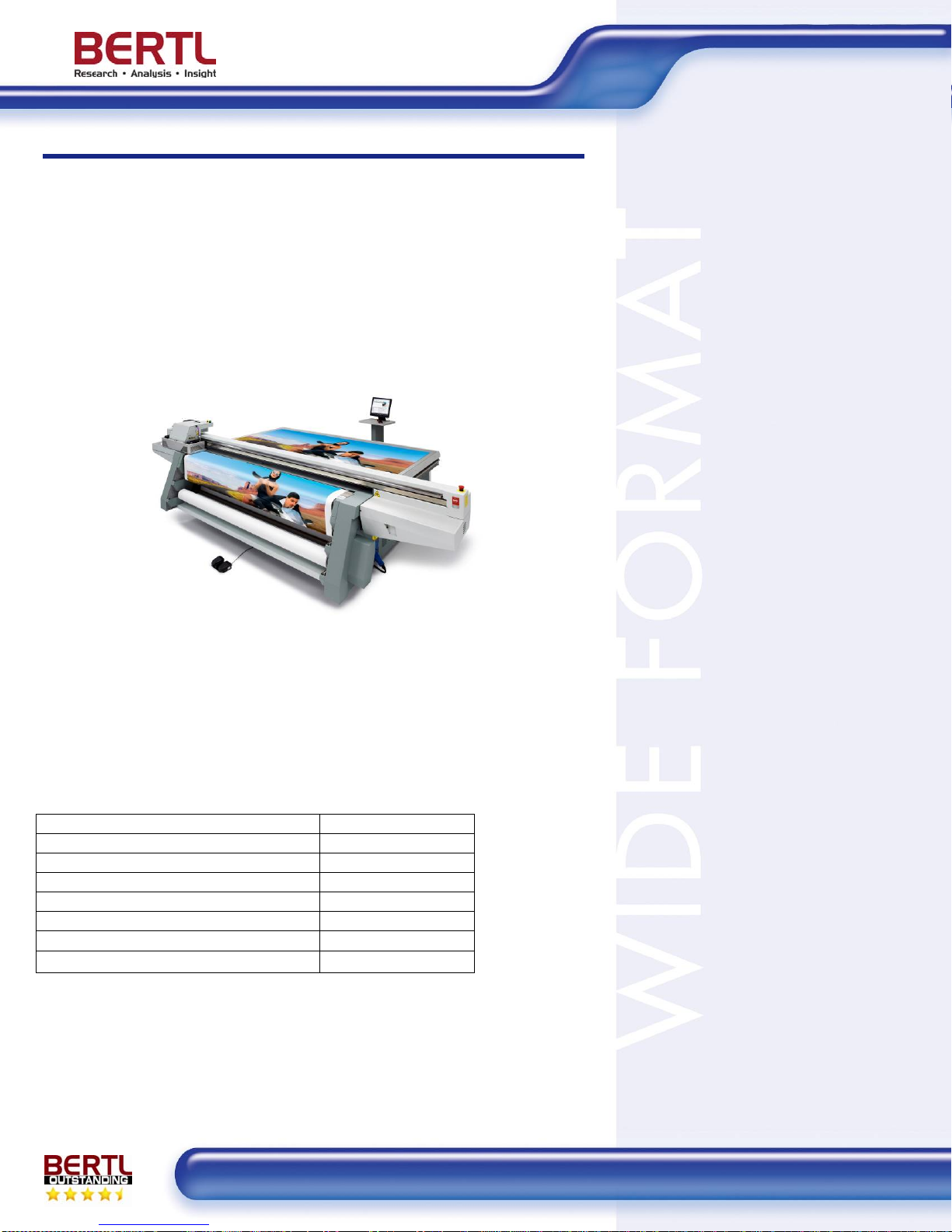

The Océ Arizona 350 GT is a four color (CMYK) printer with an option for

white ink. The UV flatbed inkjet printer is capable of producing large-format

images on various rigid and flexible media. The printer consists of a large

vacuum table and moving gantry. The material is held flat and stationary on

the vacuum table during printing. The gantry contains a carriage that sweeps

across the table as the gantry moves in steps along the length of the table to

print an image on the media. In addition to the benefits of stationary

positioning, the use of UV ink technology on rigid material eliminates finishing

processes such as mounting and lamination.

The Océ Arizona 350 GT printer is a 98.4” x 49.2” flatbed printer.

The Océ Arizona 350 GT printer uses UV curable inks and Océ VariaDot™

imaging technology to deliver near-photographic image quality on a wide

range of rigid and flexible media. The promise of Océ VariaDot technology on

a four color ink printer is that it uses less ink than a comparable six color ink-

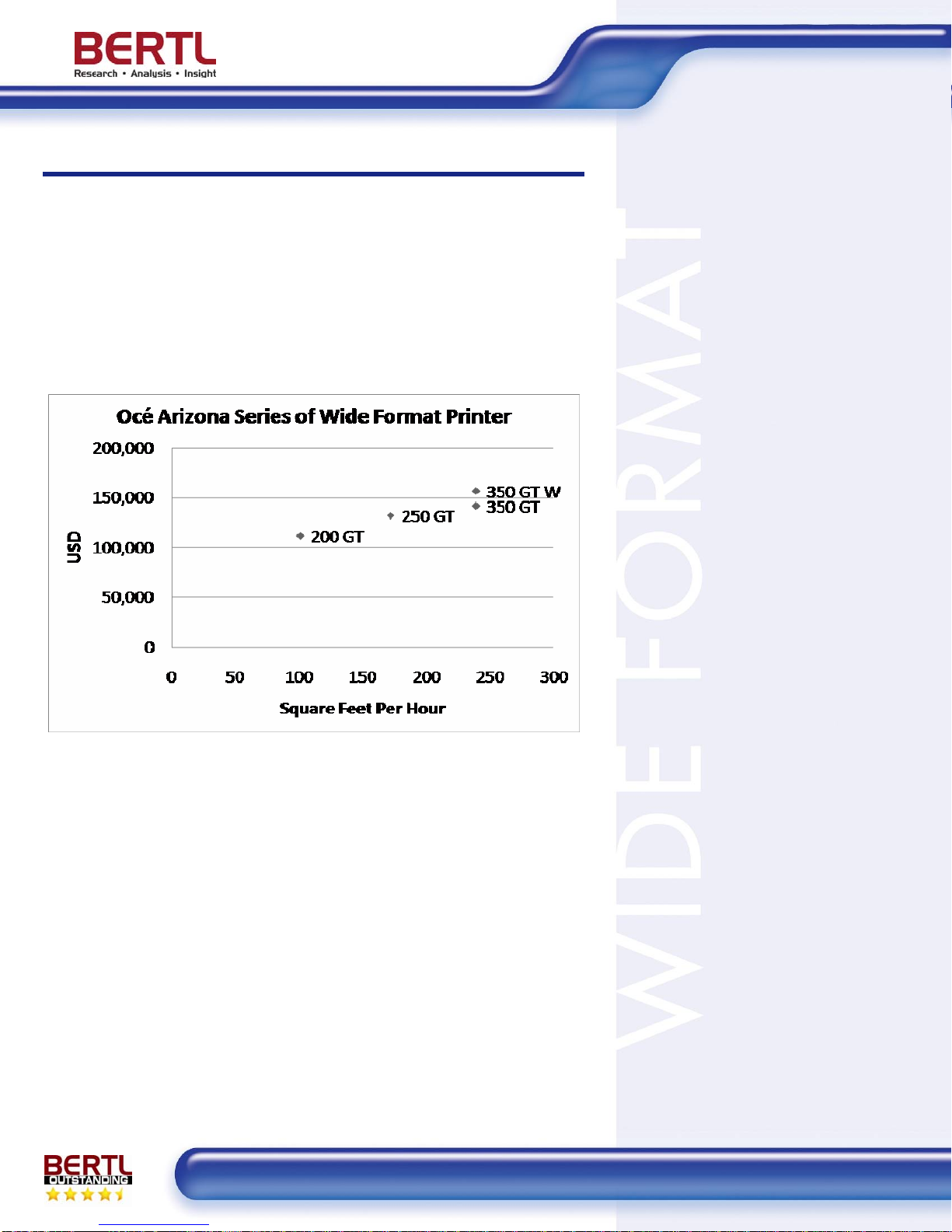

based system. The maximum production speed is 239 ft2/hr for rigid media

and 188 ft2/hr for roll feed media. Print speed also varies based on print mode

and the use of white ink as indicated in the table below.

Print Mode Print Speed

Production: 239 ft2/hr

Quality: 164 ft2/hr

Quality-Matte: 117 ft2/hr

Quality-Density: 91 ft2/hr

Fine Art: 133 ft2/hr

White Ink - Quality 3 Layer: 55 ft2/hr

White ink - Quality 2 Layer: 82 ft2/hr

The Océ Arizona 350 GT printer is a flatbed printer with a roll feed option

allowing a more flexible mix of both rigid and flexible media. The print width is

somehow less for the flexible roll feed option — 86.2” compared to 98.4” for

rigid media.

To ensure that the media is staying flat,

the printer has a heavy vacuum pump

preventing any media slipping during

print. Since not all prints need to reach

the maximum width of 98.4”, the printer’s

flatbed is divided into three different

zones to ensure better suction for smaller

media sizes. The vacuum zones are user-

controllable.

The printer and the Controller station are

connected to the local LAN through an

Ethernet connection in the back, which

supports 100 Mbit and 1 Gbit fast

Ethernet.

The Océ Arizona 350 GT printer comes

pre-configured with either a four-color ink

system or a factory-installed five- color ink

system that includes the white ink option.

Printers can be upgraded with the white

ink option in the field. The physical print

resolution depends on the print mode.

The printer comes with the option of

ONYX ProductionHouse RIP v7.2 for

$4,995 to facilitate printing from any

locally connected computer.

The Océ Arizona 350 GT flatbed printer

has a footprint of 8.7 ft x 6.5 ft for the

table. Including the gantry the width grows

to 13.4 ft, requiring a fairly large room for

operation. To make it possible to get this

in your production room, the printer can

be tilted 90º to move it into your facility

with the aid of the Tilt-N-Go rigging

accessory, thereby preventing the need to

break down walls to get it in there.

Lastly the Océ Arizona 350 GT printer

uses a single phase voltage of 208V and

a rated current of 16 amps.