Issue2

November 14, 2011

- 9 -

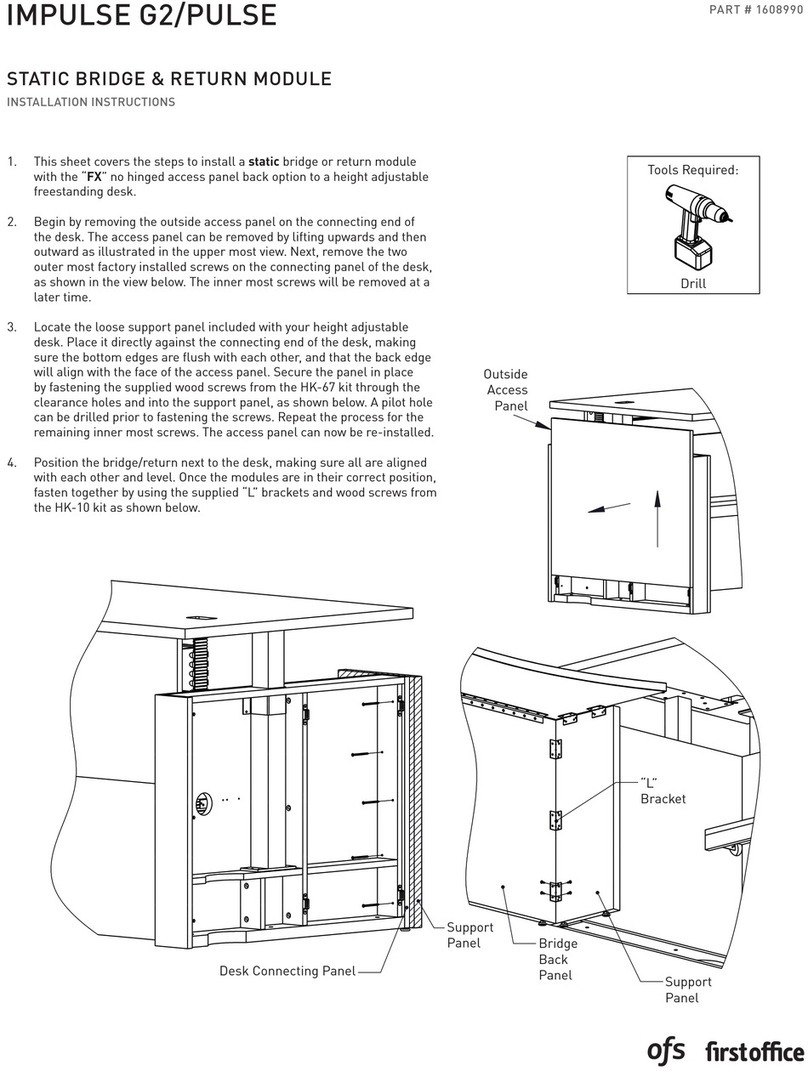

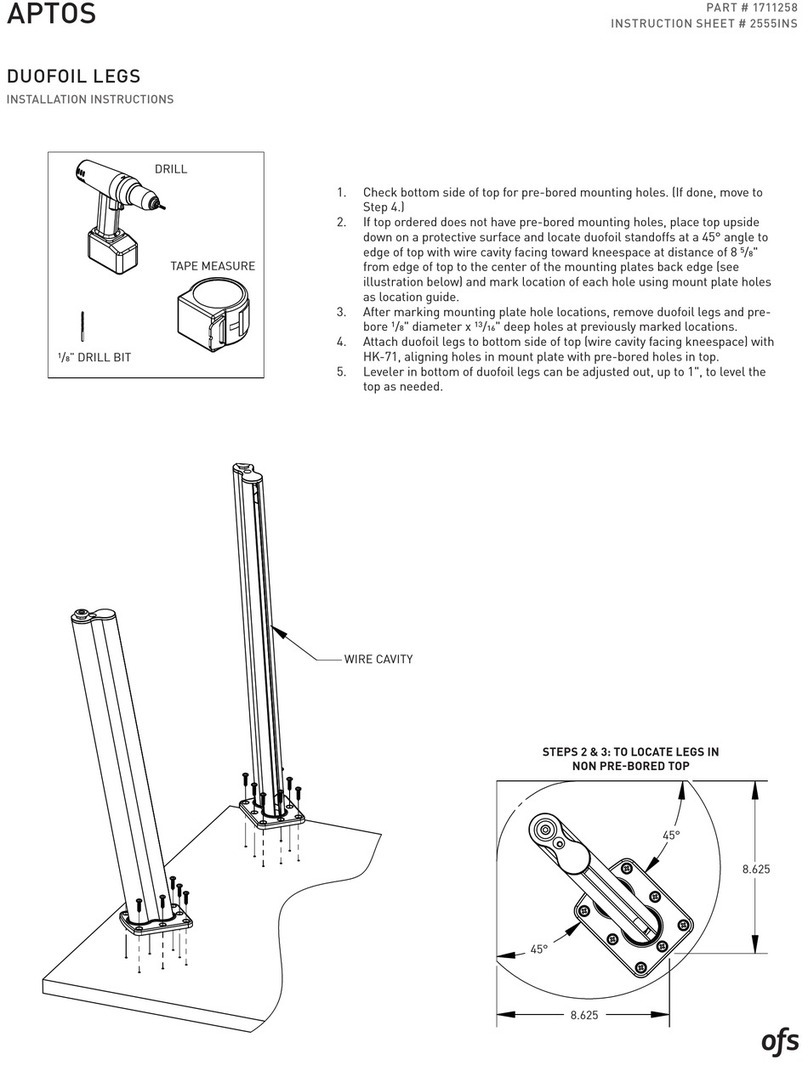

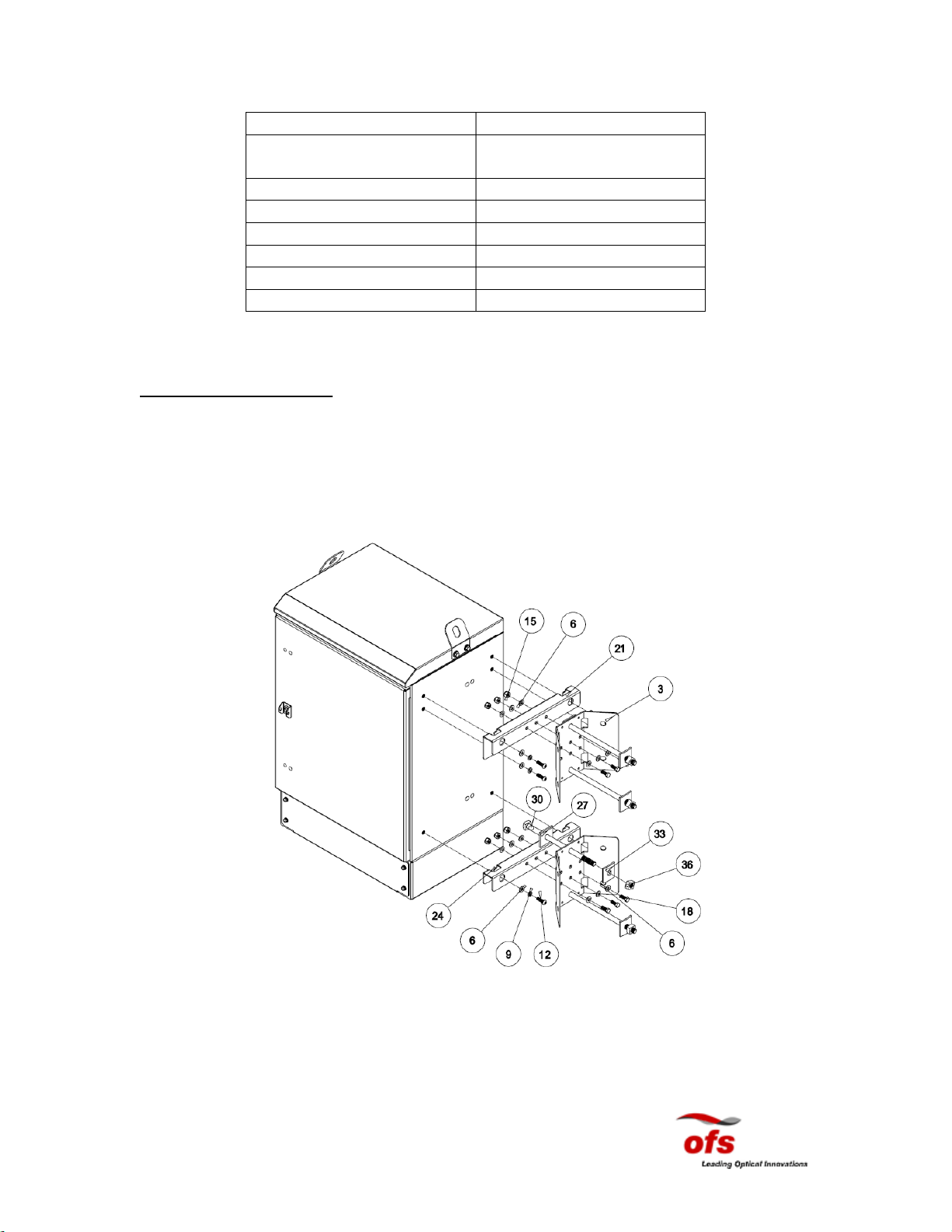

Pole Mounting Installation Procedures

Use this procedure to mount the cabinet on an 8 to 14 inch diameter wooden pole. See

figures 6 and 7 on previous pages.

Have the following equipment ready before beginning this procedure:

-One drill

-One ¾” (19.05 mm) x 12” (30.5 cm) drill bit

-One 9/16” wrench

-Two 15/16” wrenches

-A pencil

-Optional small pole mounting kit

1. Pre-assemble the upper and lower horizontal brackets to the vertical brackets as

shown in the figures on the preceding pages.

2. Select a convenient mounting location on the pole.

3. Install the pole mounting template as an aid. Drill four (4) ¾” diameter holes in

the pole per the dimensions in Figure 7 for the four (4) 5/8” bolts (item 30 in

Figure 6).

4. Insert machine bolt (item 30) through mounting bracket and into the mounting

hole and press bolt and bracket flush against the pole.

5. Place round-cupped washer (item 33), with the concave side in, on bolt and finger

tighten nut.

6. Repeat step 4 and 5 for remaining bolts.

7. Secure the mounting bracket assemblies to the pole by securely tightening the

machine bolts to 40 ft-lbs for wooden posts.

8. Holes are provided in the side of the vertical brackets for lag bolt installation for

larger poles. The brackets can also be banded to metal poles.

9. Engage the four (4) 3/8” cap screws (item 12), which slide into the keyed slots

provided in the horizontal brackets, into the cabinet as shown in the diagram.

10. Using proper lifting and safety equipment, place cabinet on mounting bracket

assemblies using supplies 3/8” hardware and tighten to 45 ft-lbs. Lifting eyelets

are provided on the cabinet for hoisting it in place.