RECTANGULAR LEG

SQUARE LEG

SQUARE LEG

RECTANGULAR LEG

ELECTRIC ADJUSTABLE HEIGHT

BASE ASSEMBLY

RECTANGULAR OR SQUARE COLUMNS

Attach mounting hardware to

•

top of columns.

Use (6) M6x 12MM socket head

•

cap screws, per column, to attach

L-brackets to themotor housing

on the rectangular column.

Use (4) M6 x 16MM at head

•

cap screws, per column ,to

attach mounting plate to top

of column.

Place work surface bottom side

•

up on a non-marring surface.

Align holes on mounting plate

•

with pre-drilled holes on bottom

side of work surface.

Fasten mounting hardware to

•

worksurface using (8) #12 X 1"

truss head screws per column.

Series:

Part #:

RECTANGULAR LEG

SQUARE LEG

SQUARE LEG

RECTANGULAR LEG

ELECTRIC ADJUSTABLE HEIGHT

BASE ASSEMBLY

RECTANGULAR OR SQUARE COLUMNS

Attach mounting hardware to

•

top of columns.

Use (6) M6x 12MM socket head

•

cap screws, per column, to attach

L-brackets to themotor housing

on the rectangular column.

Use (4) M6 x 16MM at head

•

cap screws, per column ,to

attach mounting plate to top

of column.

Place work surface bottom side

•

up on a non-marring surface.

Align holes on mounting plate

•

with pre-drilled holes on bottom

side of work surface.

Fasten mounting hardware to

•

worksurface using (8) #12 X 1"

truss head screws per column.

Series:

Part #:

RECTANGULAR LEG

SQUARE LEG

SQUARE LEG

RECTANGULAR LEG

ELECTRIC ADJUSTABLE HEIGHT

BASE ASSEMBLY

RECTANGULAR OR SQUARE COLUMNS

Attach mounting hardware to

•

top of columns.

Use (6) M6x 12MM socket head

•

cap screws, per column, to attach

L-brackets to themotor housing

on the rectangular column.

Use (4) M6 x 16MM at head

•

cap screws, per column ,to

attach mounting plate to top

of column.

Place work surface bottom side

•

up on a non-marring surface.

Align holes on mounting plate

•

with pre-drilled holes on bottom

side of work surface.

Fasten mounting hardware to

•

worksurface using (8) #12 X 1"

truss head screws per column.

Series:

Part #:

RECTANGULAR LEG

SQUARE LEG

SQUARE LEG

RECTANGULAR LEG

ELECTRIC ADJUSTABLE HEIGHT

BASE ASSEMBLY

RECTANGULAR OR SQUARE COLUMNS

Attach mounting hardware to

•

top of columns.

Use (6) M6x 12MM socket head

•

cap screws, per column, to attach

L-brackets to themotor housing

on the rectangular column.

Use (4) M6 x 16MM at head

•

cap screws, per column ,to

attach mounting plate to top

of column.

Place work surface bottom side

•

up on a non-marring surface.

Align holes on mounting plate

•

with pre-drilled holes on bottom

side of work surface.

Fasten mounting hardware to

•

worksurface using (8) #12 X 1"

truss head screws per column.

Series:

Part #:

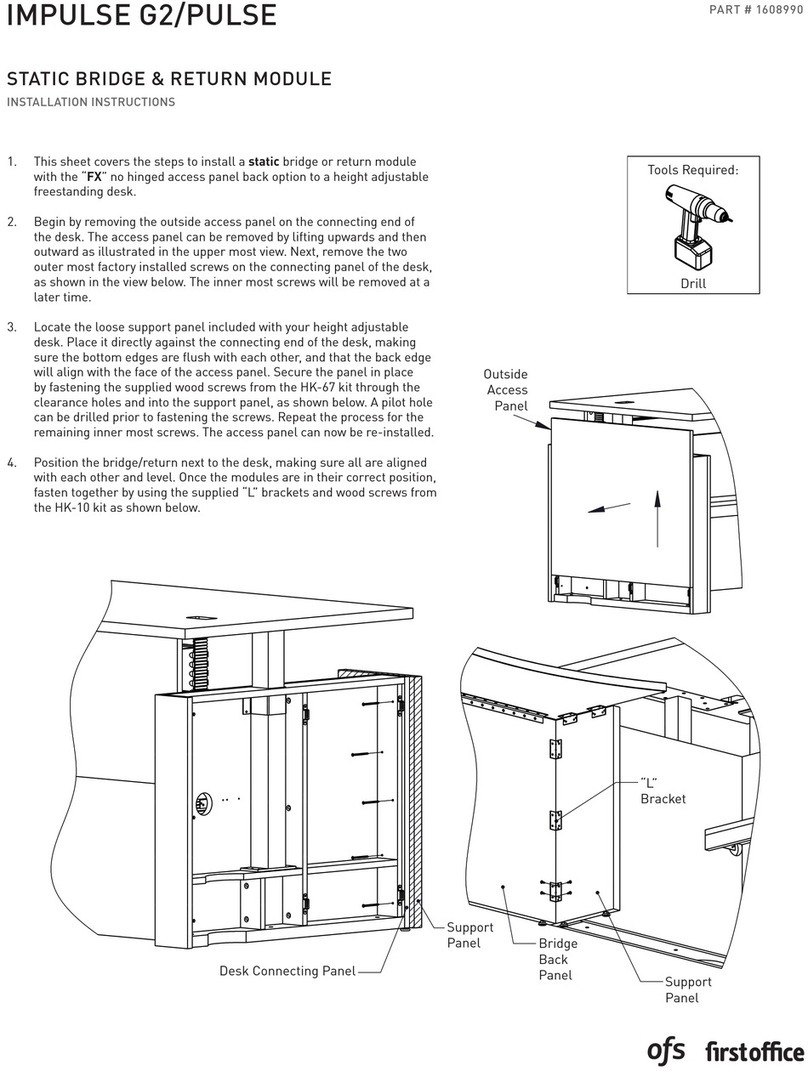

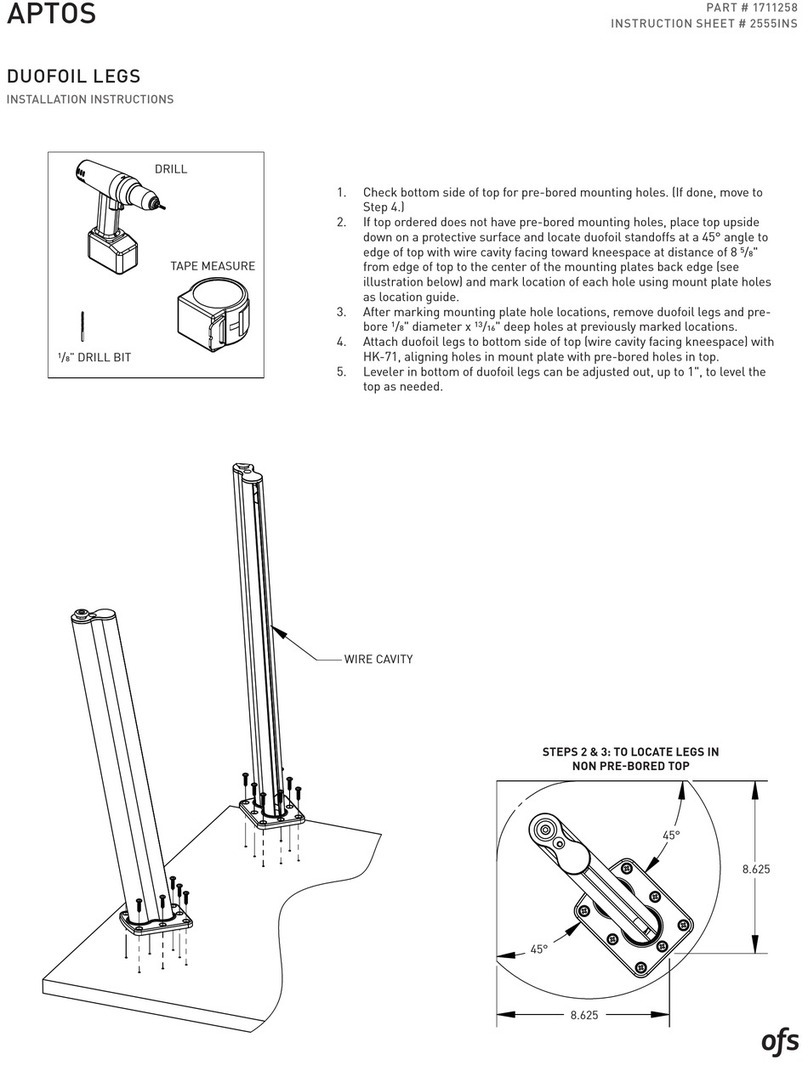

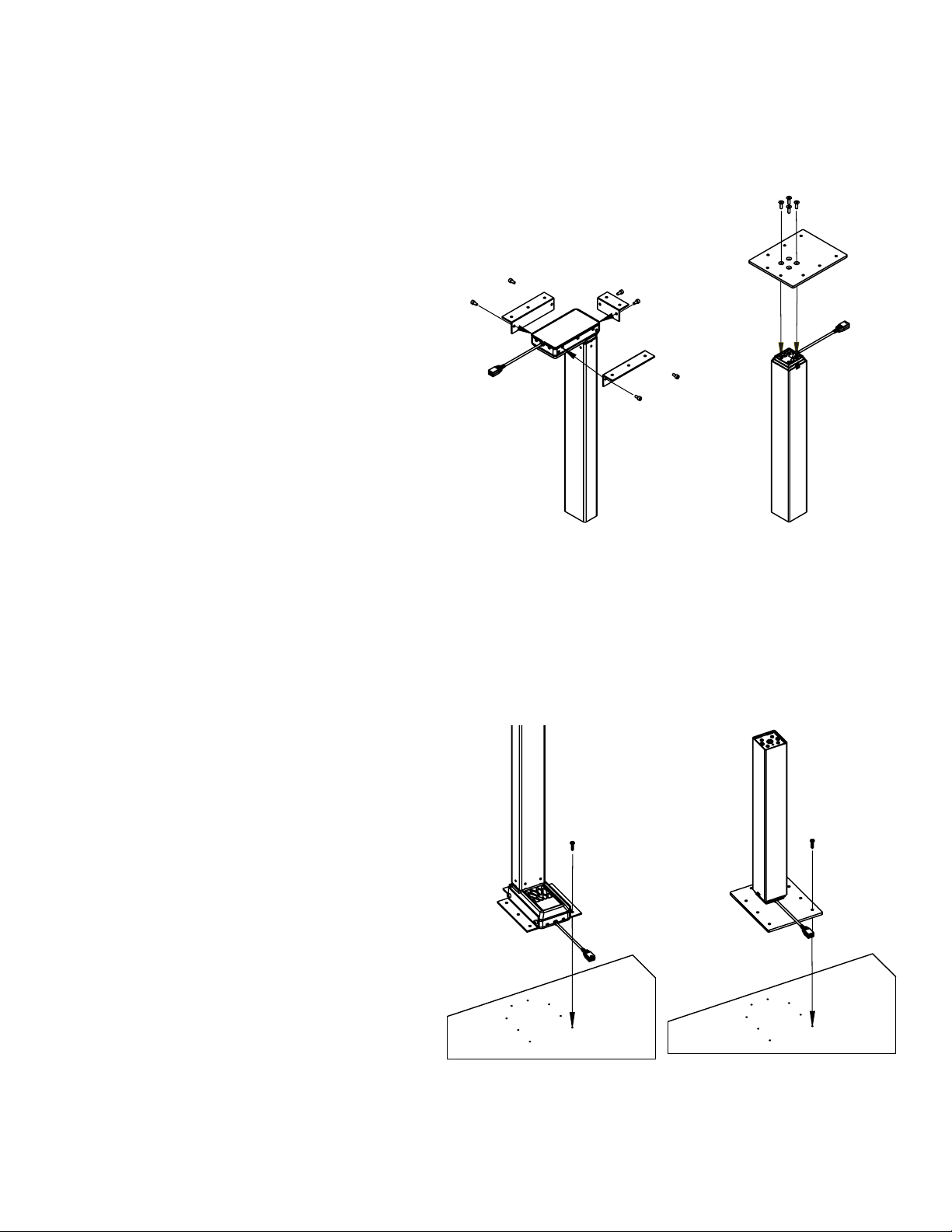

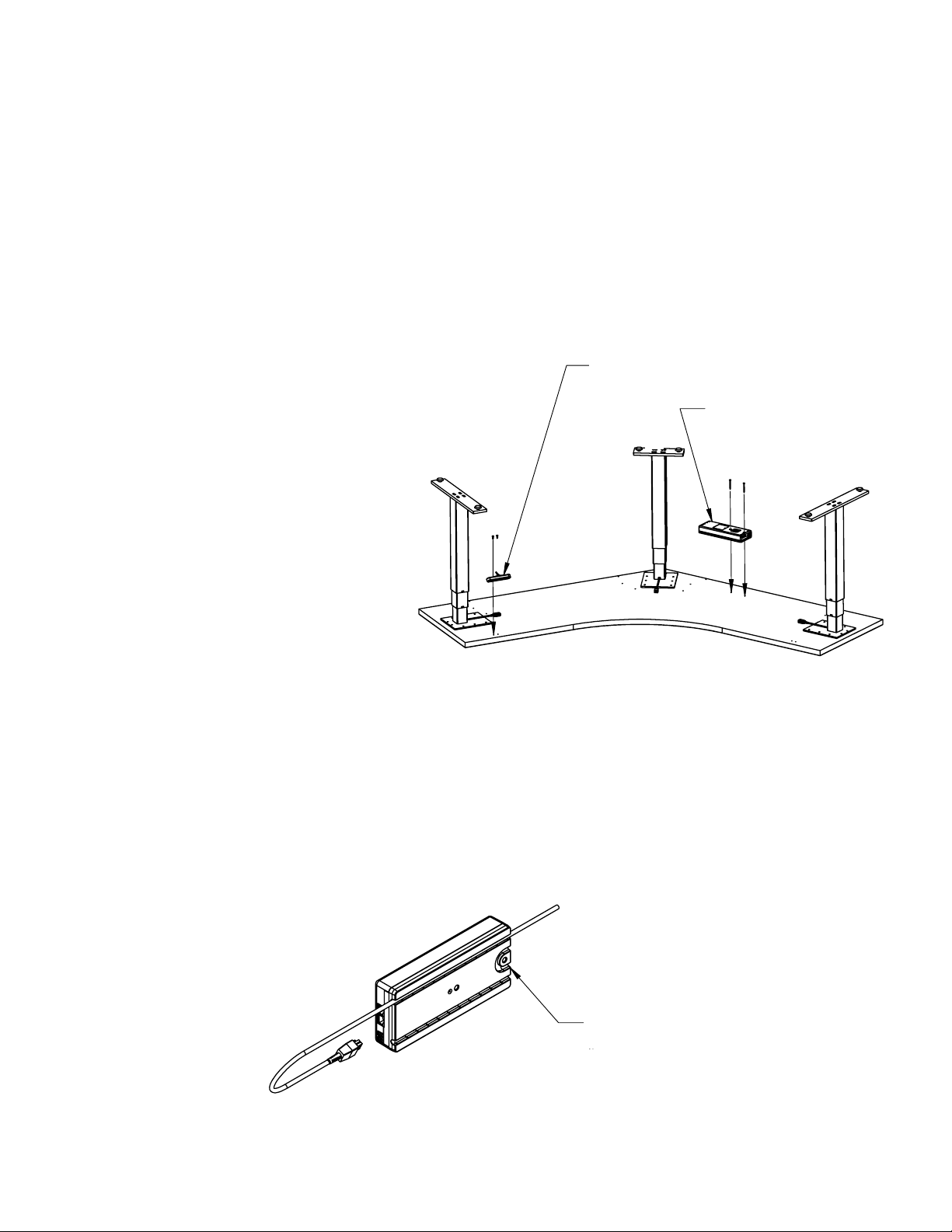

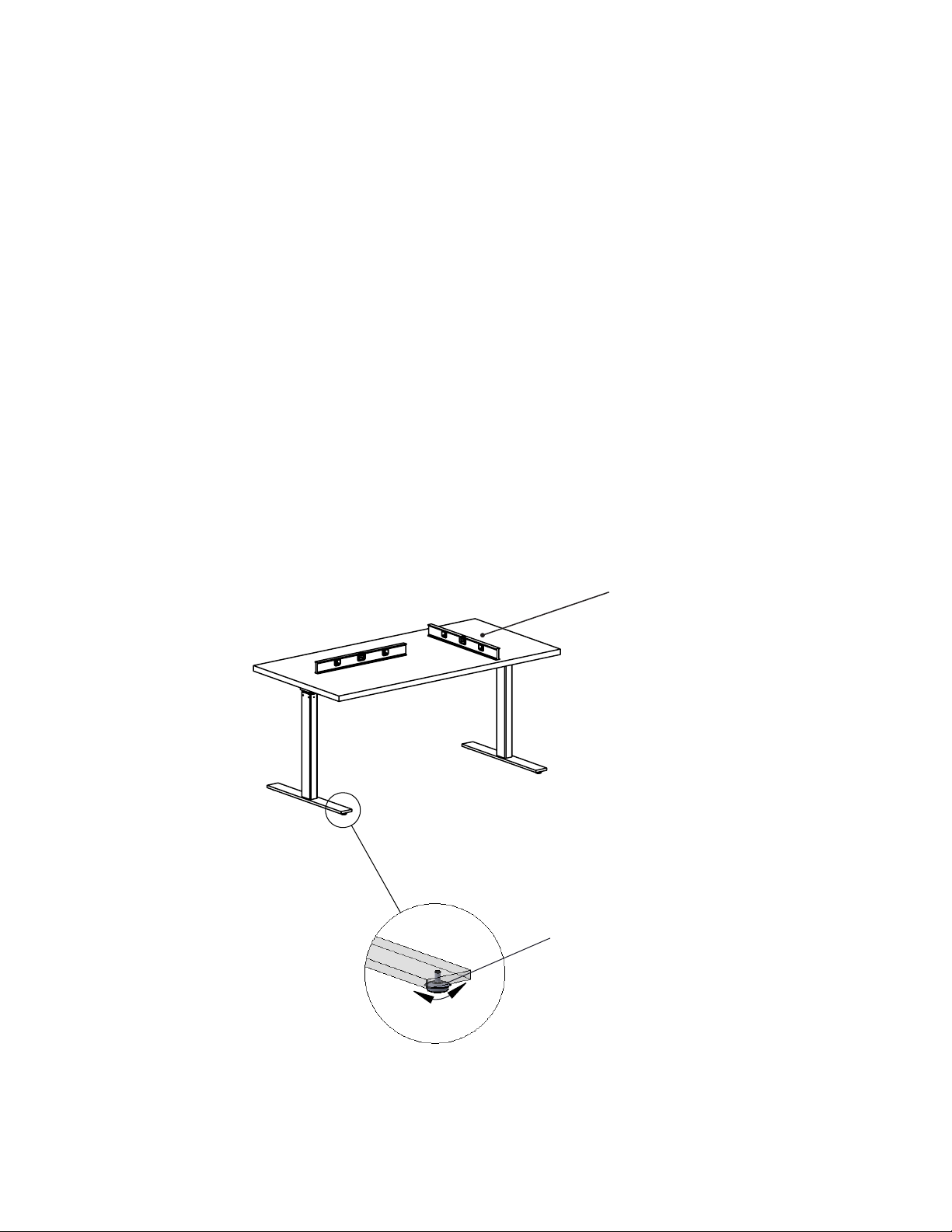

Rectangular or Square Columns

1. Attach mounting hardware to top of columns.

2. Use (6) M6 x 12MM socket head cap screws,

per column, to attach L-brackets to the motor

housing on the rectangular column using a

5mm allen wrench.

3. Use (4) M6 x 16MM flat head cap screws, per

column, to attach mounting plate to top of

column using a 5mm allen wrench.

4. Place worksurface bottom side up on a non-

marring surface.

5. Align holes on mounting plate with pre-drilled

holes on bottom side of worksurface.

6. Using a phillips head on the cordless

screwdriver, fasten mounting hardware to

worksurface using (8) #12 X 1” truss head

screws per column.

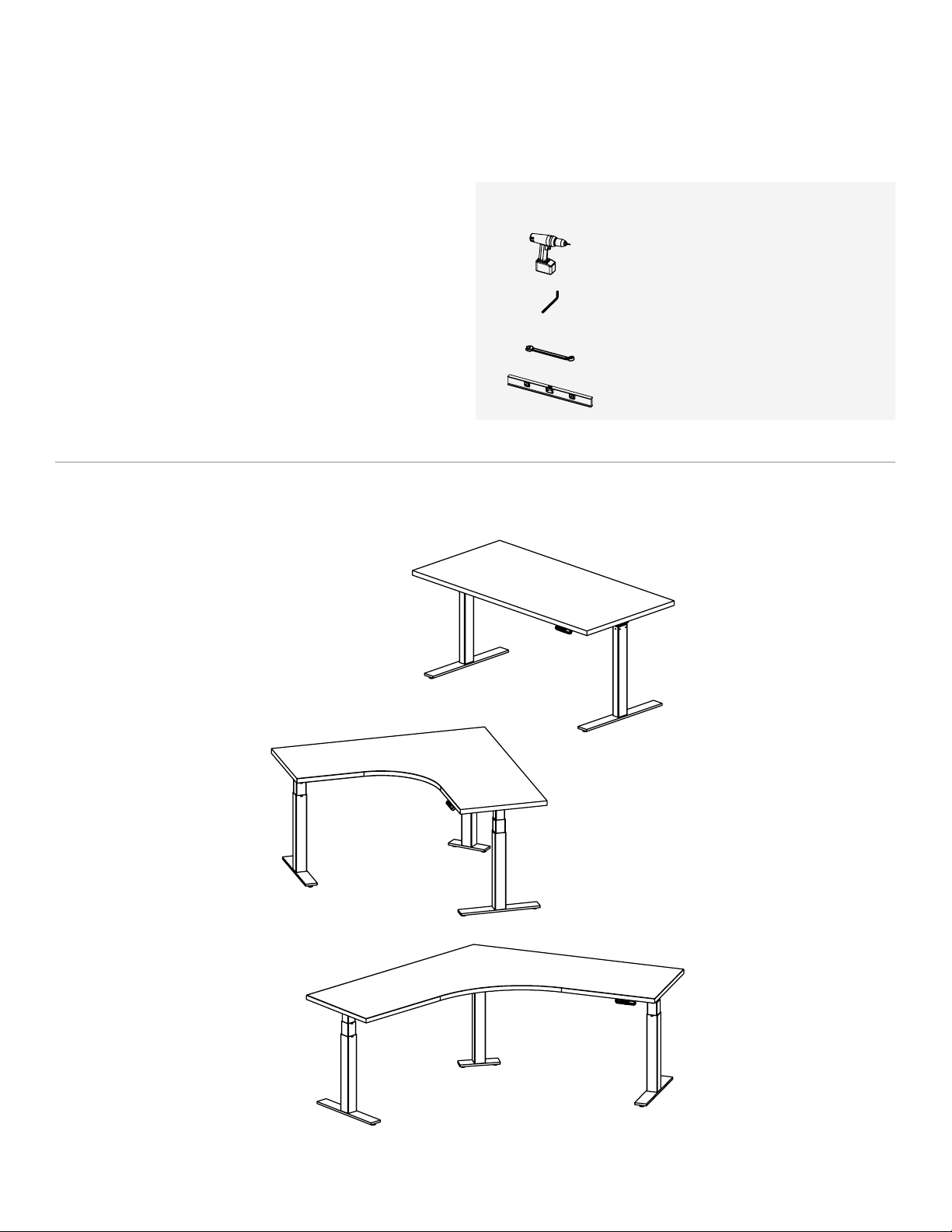

Electric Height Adjustable Tables

ASSEMBLY INSTRUCTIONS

4 | OFS BRANDS

RECTANGULAR

LEG

RECTANGULAR

LEG

SQUARE

LEG

SQUARE

LEG