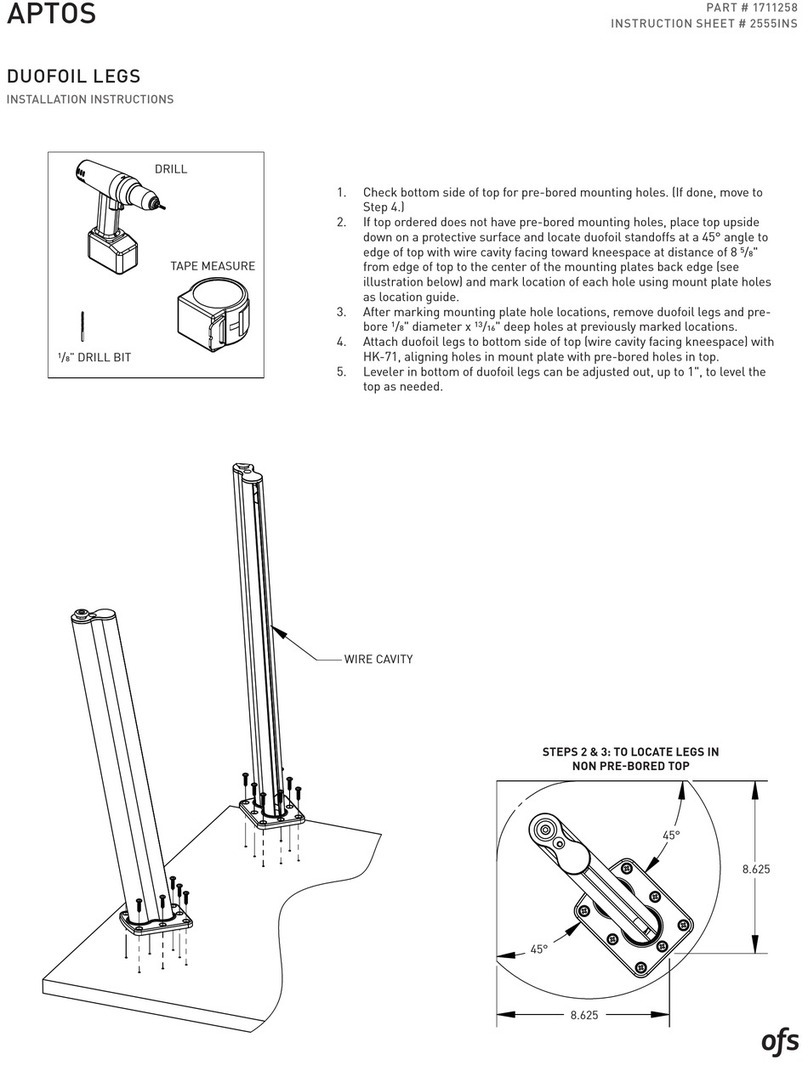

PART # 1609011

HEIGHT ADJUSTABLE DESK

SET UP GUIDE

IMPULSE G2/PULSE

TOOLS REQUIRED:

Drill

PS-77

Factory Installed

Location

Desired

Location

Wire Manager shown

installed on the right side

Upper Position

Lower Position

Mount

Clip

Wire Manager

Shelf Location

Power Cord

Worksurface Location

HA Desk Set Up Guide

This sheet covers the details to correctly set up your height adjustable unit.

•

The control switch has been temporarily mounted in a protected area underneath the worksurface to prevent any damage

•

during shipping. Remove the mounting screw(s) and place the switch in a visible and obstruction free postion. Fasten the

switch to the worksurface utilizing the two mounting holes on the bracket.

NOTE:

It is recommended to use a power supply (PS-77) to power the height adjustable unit if any electrical accessories are

•

installed onto it. This will aid in the process of properly managing power cords underneath the worksurface.

A wire manager is included to use with your desk and is intended to be installed in between the worksurface and fixed shelf.

•

To assemble the wire manager, slide the mounting clip onto the manager as shown in the views above. The slot on the clip

aligns with the flat narrow sections of the manager.

The wire manager can be installed on either the left or right side of the fixed shelf, near the corner notches. Raise the

•

worksurface to the upper most height, then locate an area above and below that will allow for a clear mounting position.

Approximate locations are shown in the views above. Fasten the mounting clips, making sure the mounting clips are

relatively straight and parallel with each other. This will ensure that the wire manager will not bind or stress when the

worksurface is lowered.

Wires and cables can then be passed through the wire manager, the notch of the shelf, and finally routed through the

•

pedestal and/or base as illustrated in the views above. To gain access inside the panel base, lift upward and then outward

on the outside end panel and set aside.

1609011

Rev:

Dwg:

TOOLS REQUIRED:

Drill

Outside Access

Panel

Support

Panel

Desk

Connecting

Panel

Bridge

Back Panel

Support

Panel

"L" Bracket

Static Bridge & Return Module Installation

This sheet covers the steps to install a

static

bridge or return module with the "

FX

" no hinged access panel back

•

option to a height adjustable freestanding desk.

Begin by removing the outside access panel on the connecting end of the desk. The access panel can be

•

removed by lifting upwards and then outward as illustrated in the upper most view. Next, remove the two outer

most factory installed screws on the connecting panel of the desk, as shown in the view above. The inner most

screws will be removed at a later time.

Locate the loose support panel included with your height adjustable desk. Place it directly against the

•

connecting end of the desk, making sure the bottom edges are flush with each other, and that the back edge

will align with the face of the access panel. Secure the panel in place by fastening the supplied wood screws

from the HK-67 kit through the clearance holes and into the support panel, as shown above. A pilot hole can be

drilled prior to fastening the screws. Repeat the process for the remaining inner most screws. The access panel

can now be re-installed.

Position the bridge/return next to the desk, making sure all are aligned with each other and level. Once the

•

modules are in their correct position, fasten together by using the supplied "L" brackets and wood screws from the

HK-10 kit as shown above.

1608990

Rev:

Dwg:

Drill

Tools Required:

PS-77

1. This sheet covers the details to correctly set up your height adjustable unit.

2. The control switch has been temporarily mounted in a protected area underneath the worksurface to

prevent any damage during shipping. Remove the mounting screw(s) and place the switch in a visible

and obstruction free postion. Fasten the switch to the worksurface utilizing the two mounting holes on

the bracket. NOTE: It is recommended to use a power supply (PS-77) to power the height adjustable

unit if any electrical accessories are installed onto it. This will aid in the process of properly

managing power cords underneath the worksurface.

3. A wire manager is included to use with your desk and is intended to be installed in between the

worksurface and fixed shelf. To assemble the wire manager, slide the mounting clip onto the manager

as shown in the views below. The slot on the clip aligns with the flat narrow sections of the manager.

4. The wire manager can be installed on either the left or right side of the fixed shelf, near the corner

notches. Raise the worksurface to the upper most height, then locate an area above and below that

will allow for a clear mounting position. Approximate locations are shown in the views below. Fasten

the mounting clips, making sure the mounting clips are relatively straight and parallel with each

other. This will ensure that the wire manager will not bind or stress when the worksurface is lowered.

5. Wires and cables can then be passed

through the wire manager, the notch

of the shelf, and finally routed through

the pedestal and/or base as illustrated

in the views below. To gain access

inside the panel base, lift upward and

then outward on the outside end panel

and set aside. Desired

Location

Factory

Installed

Location

Worksurface Location

Power Cord

Shelf Location

Upper Position

Lower Position

Wire Manager shown

installed on the right side

Wire Manager

Mount

Clip