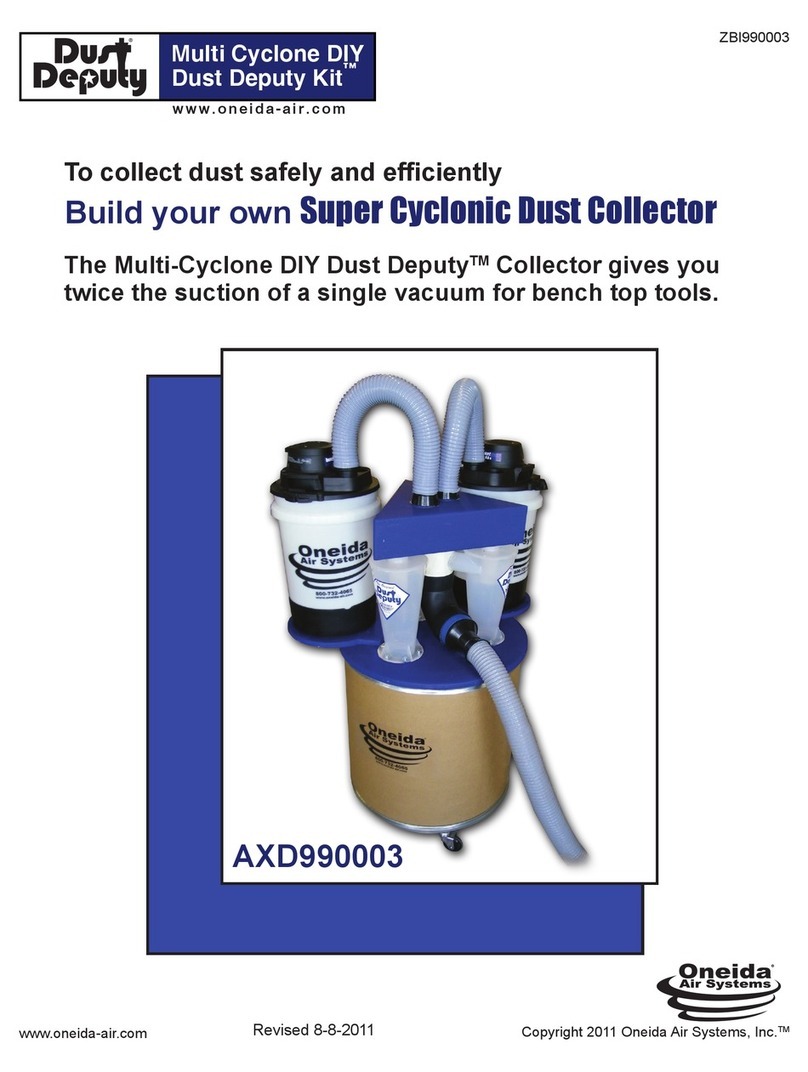

II. General Assembly

O.A.S. 2008

c

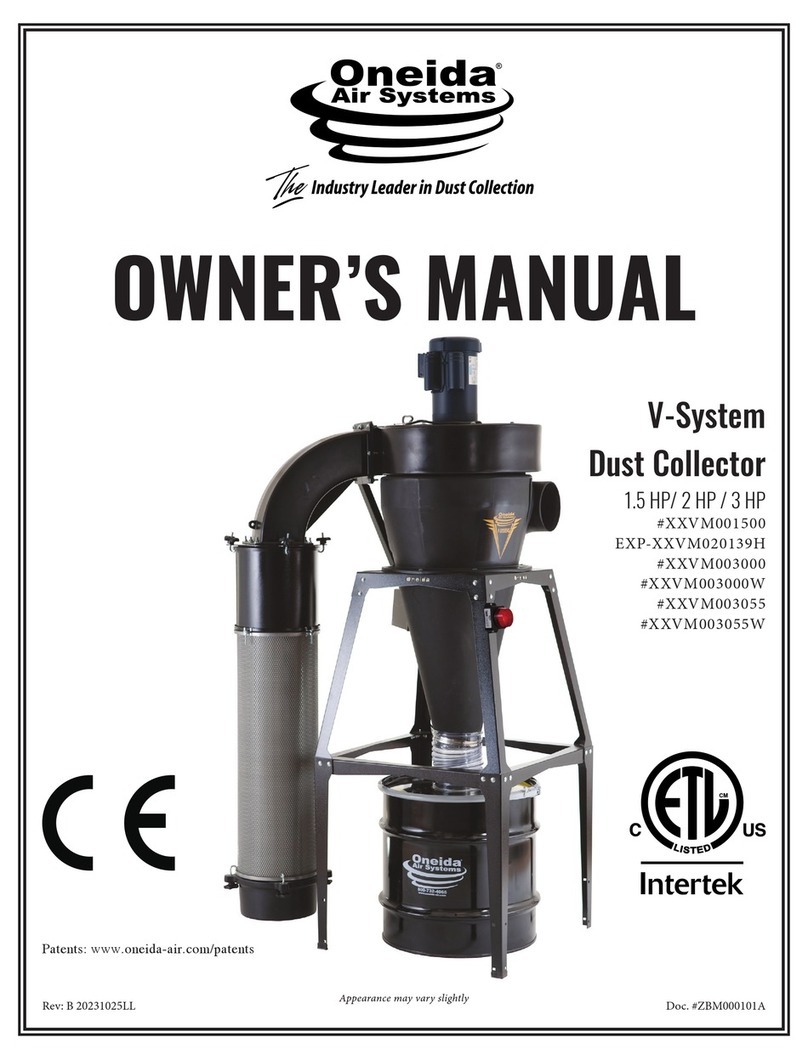

3HP High Vacuum Owners Manual

3

1. Motor/Blower Assembly BXI030101-1ph -BXI030301 - 3ph

1a. Fan Wheel - BWX164 50

1b. Magnetic Starter w/ Remote Option includes cord-

AMR 1417-1phase or - AMI0 0000 - 3ph (not pre-wired)

1c. Cord Connector- WCC0 7063 1 phase only

1d. Cord Connector Locknut - WCN340000 1 phase only

1e. 3hp Motor BMZ030170-1 ph / BMZ030370-3 ph

1f. Motor Plate - RMP00 301

1g.Fan Housing - BHX030001

3. Cyclone Barrel - SXI00 109

4. Cyclone Cone - SCX00 109

5. Plenum 8 Elbow - FPX010300

6. Thumb Nut (4) - AFT000001

7. Cartridge Filter Threaded Clamp (4) - AFX000000

7a. AFB155180 Bolt 5/16-18 x 1/ (4)

8. Fender Washer (4) - AFW170000

9. Dust Pan 8 H - FPZ016080

10. Internal Silencer (Pat. Pend.) - BSC180000

11. Filter - 18 Dia. x 6 L - FCS186 00

1 . Owners Manual - ZBM000003

13. Square to Round Inlet Transition to 6 dia. - BQX061500

14.Filter Efficiency Gauge 0-5 H 0 - VRG001005

14a. Vinyl Tubing Clear 5/16 O.D. - VRV0031 5 (8)

14b. Static Pressure Tip - VRP001875

14c. Mounting Flange for Pitot Tube - VRP010000

14d. Filter Efficiency Gauge Bracket - FXX000000

15. 55 Gal. Steel Drum Kit - SEK550901 Standard

15a. Drum Lid w/ 9 Ring - SEX550900

15b. Hose Clamps ( ) - ACB1 0000

15c. 55 Gal. Steel Drum - SES550000

15e. Flex Hose (9 dia. x 1) - DHF090000

16. Hardware Kit - AHX000000

16a. (3) 3/8 x 1 1/4 Bolts - AFS015700

16b. (14) 3/8 Washers - AFW190000

16c. (7) 3/8 Wiz Nuts - AFT00004

16d. (4) 3/8 x 1 Bolts - AFS015100

16e. (1 ) 5/16 x 1 Bolts - AFB155190

16f. ( 4) 5/16 Washers - AFW180000

16g. ( 8) 5/16 Wiz Lock Nuts AFT155175

16h. Gasket - RGZ000000 ( 5)

17. Decal - (1) Oneida Logo - ZBC000015

18. Labels

18a. Rotation Label - ZBC0000 9

18b. Caution / Exhaust Label - ZBS000004

18c. General Caution Label - ZBS000001

18d. Filter Maintenance Label - ZBS000007

18e. Caution / Check Frequently Label - ZBS000006

18f. Caution / Drum Cover Label - ZBS000005

19. Wall Bracket -Standard- SMS3000 1 optional

Optional Fan/Blower Outlet Transitions:

0. Square to 8 dia. For Fan Outlet - BQX308000 Uncrimped

1. Square to 8 dia. For Fan Outlet - BQX308001 Crimped

1e

1f

16h

16h

16h

1g

3

4

15b

15e

15b

15c

5

10

11

(8) 5/16 Nuts

(1 ) 5/16 x 1 Bolts

(1 ) 5/16 Washers

(1 ) 5/16 Nuts

(4) 3/8 x 1 Bolts

(4) 3/8 Washers

(4) 3/8 Nuts

Caution

Check Dust Bin Frequently For

Smoldering Materials. Empty Bin Before

Lea ing Shop.

Drum co er must be in place when system

is operating to pre ent motor o erheating!

An airtight seal between the cyclone and

drum will pro ide the necessary resistance

needed to pre ent motor o erheating!

Caution

Caution:

If exhaust air is ented outside you must pro ide

make up/return air.

Flue gases (carbon monoxide) can be drawn into

the shop from furnaces, water heaters or other

appliances.

To avoid personal injury or property damage, read owners manual thoroughly before

installing and operating system. (Read section on collector location and fire hazards.)

This collector is for use with WOOD DUST ONLY!

Keep fire extinguishers handy at all times.

Do not use this product to collect other types of dusts or fumes.

(Fire or explosion may occur!)

Do not introduce sparks or sources of ignition into collector.

Personnel should stay at least 20 ft. away from operating system.

(Deflagration Hazard)

Empty and check dust bin frequently for possible smoldering materials.

Rotating blades inside. Keep hands and objects away.

Do not operate system unless COMPLETELY assembled with dustbin.

(Personal injury or motor damage may occur!)

Consult local fire marshal before installing.

Follow all Federal, State, Local and NFPA codes when installing system.

To reduce the risk of injury from mo ing parts - unplug before ser icing.

To reduce the risk of electric shock - unplug before cleaning or ser icing.

Read Before Insta ing and Operating!

For All

Systems

Caution

(8) 5/16 Nuts

30b. 55 gal. Angle Iron Stand - ST 021055

1. Uprights - SXX000068 (4)

. Braces - SXX0000 1 (4) / SXX0000 3 (3)

3. Feet - STX00 001 (4)

Stand - Hardware Kit - AHX021023

A. (3 ) AFB155190 - 5/16 Bolts

B. (3 ) AFT155175 - 5/16 Wiz Nuts

C. (64) AFW180000 - 5/16 Flat Washers

Angle Iron Stand

Filter Maintenance

Fai ure to fo ow fi ter maintenance instructions

in owners manua wi cause fi ter to be

damaged.

B ow down fi ter at end of day with compressed

air per owners manua or b ow down when back

pressure reaches 3 water gauge - whichever

comes first. Never a ow gauge to reach 5.

6

9

- XXK030133 - 1 phase - XXK030333- 3 phase

7

8

1a

15a

Square to Round

Connects to Inlet

0

1234

5

INCHES W.C.

13

14 14a 14b

14d 14c

0, 1