Contents

Safety 3

Highlighting Safety Instructions........................................................................................................................... 3

Intended Use ....................................................................................................................................................... 3

Basic Safety Instructions...................................................................................................................................... 4

Maximum Ratings................................................................................................................................................ 4

Naming Product and System Components 5

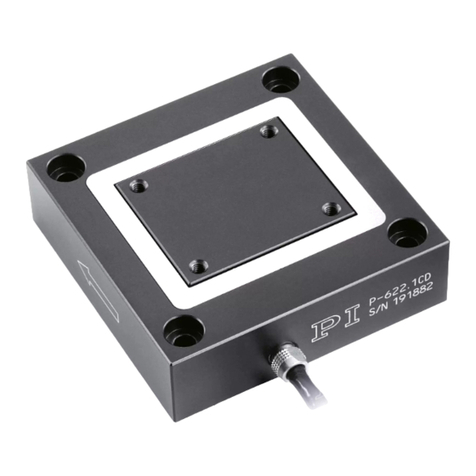

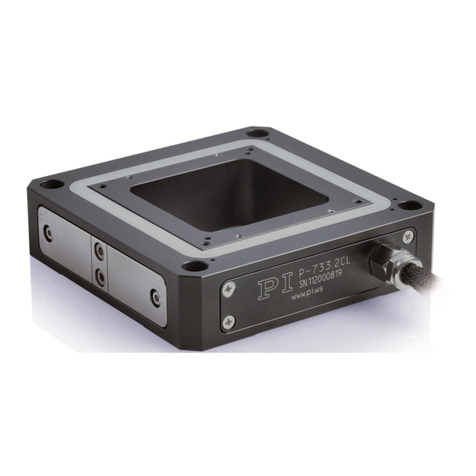

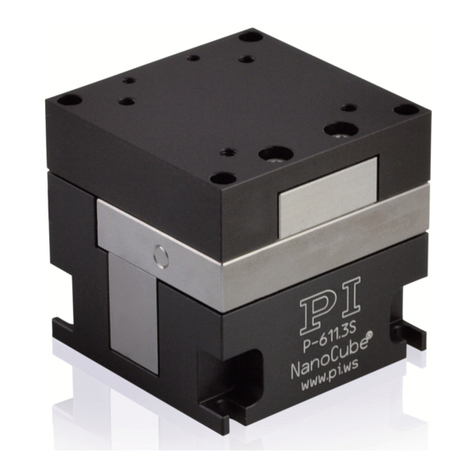

Product Scheme................................................................................................................................................... 5

Further Information on the Product and the System Components .................................................................... 6

Installation and Startup 6

Unpacking/Scope of Delivery .............................................................................................................................. 6

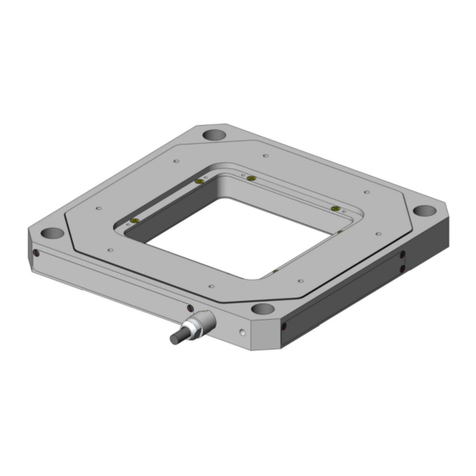

Mechanical Installation ....................................................................................................................................... 7

Mounting the Positioner onto a Surface......................................................................................................................... 7

Mounting the Payload on the Platform ........................................................................................................................11

Electrical Installation ......................................................................................................................................... 12

Connecting the C-663.12, C-863.11, C-863.12 or C-884 Controller .............................................................................. 12

Integration into the Control Software and Initial Test ...................................................................................... 14

Coordinate System / Direction of Motion.....................................................................................................................15

Maintenance, Cleaning, Troubleshooting, and Disposal 16

Maintenance...................................................................................................................................................... 16

Cleaning ............................................................................................................................................................. 16

Troubleshooting ................................................................................................................................................ 17

Moving the Platform by Hand.......................................................................................................................................17

Repair and Warranty ......................................................................................................................................... 18

Disposal ............................................................................................................................................................. 18

Appendix 19

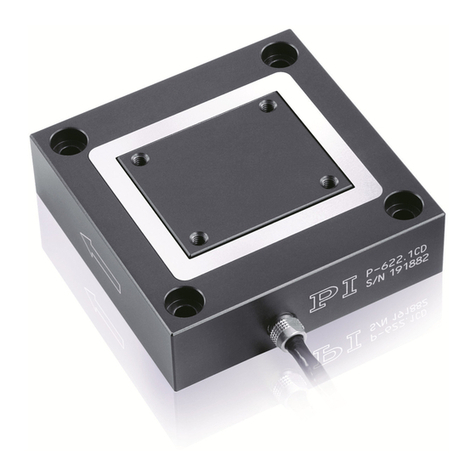

Model Range, Characteristics (Differences) ...................................................................................................... 19

Ambient Conditions and Classifications ............................................................................................................ 19

Data ................................................................................................................................................................... 20

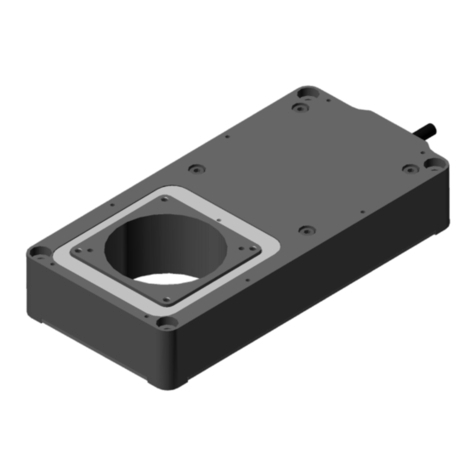

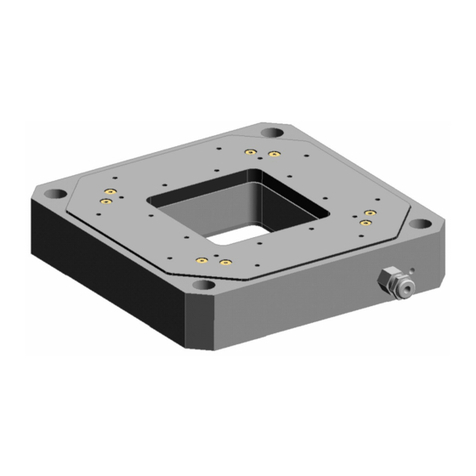

Dimensions ........................................................................................................................................................ 21

HD D-Sub 26 Pin Assignment............................................................................................................................. 22

Options and Additional Accessories .................................................................................................................. 23

Mounting Adapter (Order Separately)..........................................................................................................................23

Adapter Cable for Connecting to the C-863.11 or C-884 Controller ............................................................................. 23

Multi-Axis Systems ........................................................................................................................................................ 23

X/Y Combination Mounting Diagram ............................................................................................................................ 24

X/Z Combination Mounting Diagram (with Mounting Adapter)...................................................................................25

Legal Information .............................................................................................................................................. 26

CE Compliance...............................................................................................................................................................26

Figures, Commitment, Actuality ...................................................................................................................................26

Copyright.......................................................................................................................................................................26

Contact Person, Feedback............................................................................................................................................. 26