1About this Document 1

1.1 Objective and Target Group of this User Manual ...................................................... 1

1.2 Symbols and Typographic Conventions...................................................................... 1

1.3 Definition of Terms..................................................................................................... 2

1.4 Figures ........................................................................................................................ 2

1.5 Other Applicable Documents ..................................................................................... 2

1.6 Downloading Manuals................................................................................................ 3

2Safety 5

2.1 Intended Use .............................................................................................................. 5

2.2 General Safety Instructions ........................................................................................ 5

2.3 Organizational Measures............................................................................................ 7

3Product Description 9

3.1 Model Overview ......................................................................................................... 9

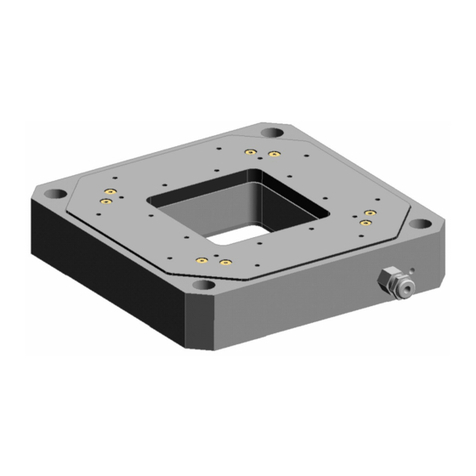

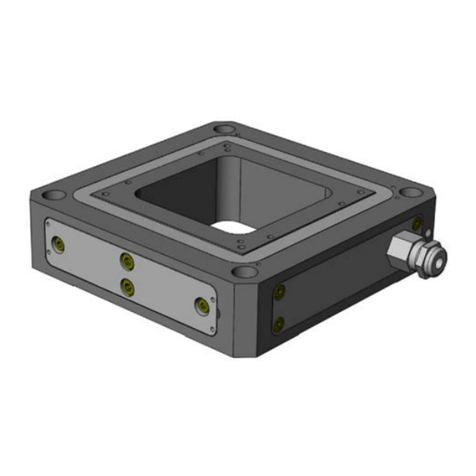

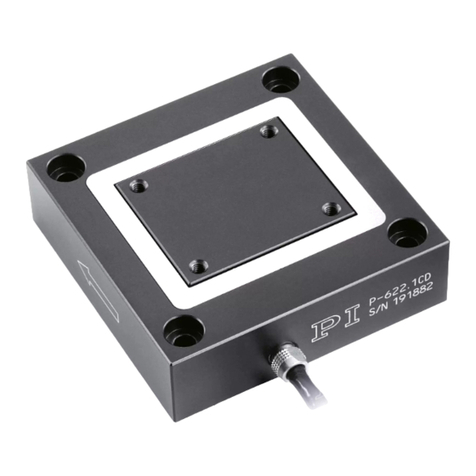

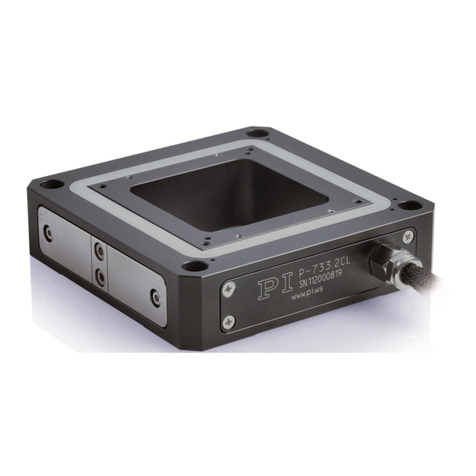

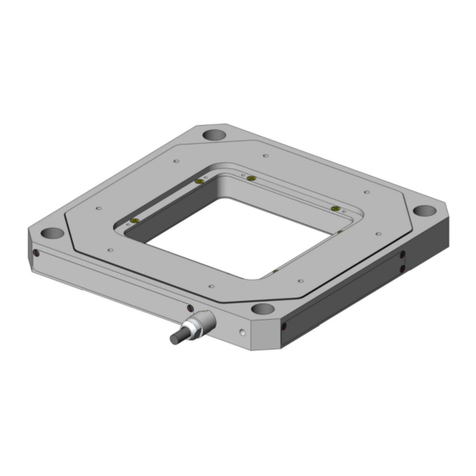

3.2 Product View .............................................................................................................. 9

3.3 Product Labeling....................................................................................................... 10

3.4 Scope of Delivery...................................................................................................... 11

3.5 Suitable Electronics .................................................................................................. 11

3.6 Technical Features.................................................................................................... 12

3.6.1 PICMA® Piezo Actuators .............................................................................. 12

3.6.2 Flexure Guides ............................................................................................. 12

3.6.3 Capacitive Sensors ....................................................................................... 12

3.6.4 ID Chip.......................................................................................................... 12

4Unpacking 13

5Installation 15

5.1 General Notes on Installing ...................................................................................... 15

5.2 Connecting the P-63x to the Protective Earth Conductor........................................ 16

5.3 Mounting the P-63x.................................................................................................. 18

5.4 Fixing the Load.......................................................................................................... 19

5.5 Connecting the P-63x to the Electronics .................................................................. 22

6Starting and Operating 23

6.1 General Notes on Starting and Operating................................................................ 23

6.2 Operating the P-63x ................................................................................................. 24

6.3 Discharging the P-63x............................................................................................... 25

Contents