système de support L2

Instructions d’installation

sistema de soporte L2

Instrucciones de instalación

Note aux revendeurs: Si vous installez ce produit pour le client, veuillez lui fournir le manuel d’utilisation après l’installation.

Merci d'avoir acheté le prolongateur de guidon Prole Design avec le système de support L2. Veuillez lire attentivement ces instructions avant d'essayer d'installer cet élément. Une

installation correcte est nécessaire pour assurer la conformité avec la politique de garantie Prole Design. Si vous n'êtes pas habitué à l'installation des prolongateurs de guidon ou

de leurs accessoires, veuillez demander l'aide de votre revendeur Prole Design local en vous connectant au site www.prole-design.com et en utilisant « recherche de revendeur »

ou en contactant le service client de Prole Design.

Nota para los distribuidores: Si instala este producto por el cliente, proporcione el manual del propietario al nalizar la instalación.

Gracias por adquirir la barra aerodinámica con sistema de soporte L2 de Prole Design. Lea íntegramente estas instrucciones antes de intentar instalar este componente. Se exige

una instalación apropiada para cumplir con la política de garantía de Prole Design. Si no está familiarizado con la instalación de barras aerodinámicas u otros accesorios, solicite

ayuda a su distribuidor Prole Design local iniciando sesión en www.prole-design.com y utilizando la opción "Encuentre un distribuidor" o comunicándose con el número del

servicio de atención al cliente de Prole Design.

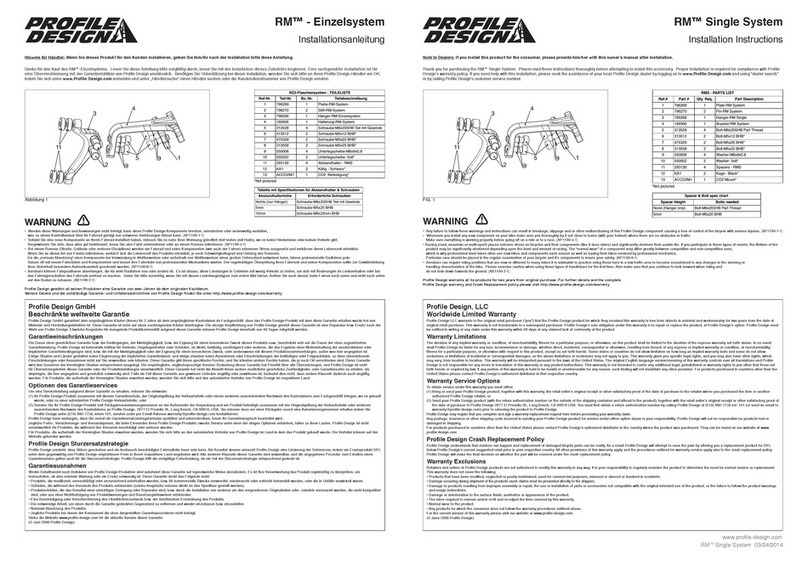

1. Extraiga los pernos M6 de la parte inferior de la abrazadera.

2. Coloque el soporte en la barra y conecte el soporte en “U” inferior en el soporte de la barra aerodinámica.

Enrosque los pernos a mano.

3. Ajuste el ancho y la inclinación de la barra a la posición deseada. Apriete de forma uniforme los pernos en 6 Nm (53 pulg-lbs).

No coloque los cables del freno o cambios entre el soporte de la barra aerodinámica y la barra base.

5. Coloque el apoyabrazos en la ubicación deseada del soporte. Inserte el perno M6 a través del apoyabrazos y en el

soporte. Utilizando la llave Allen de 4 mm, apriete el perno hasta que quede ajustado. Repita el procedimiento para el

segundo perno, dejándolo ligeramente ojo para permitir su ajuste.

NOTA: Los pernos pueden colocarse de lado a lado o de la parte frontal a la posterior para un posicionamiento

optimizado de los apoyabrazos.

6. Gire el apoyabrazos al ángulo preferido relativo a la extensión. Apriete de forma uniforme en 4,7 Nm (42 pulg-lbs).

7. Presione la almohadilla sobre el apoyabrazos y sostenga en esta posición durante 30 segundos.

Repita el mismo procedimiento para el otro apoyabrazos.

8. Vuelva a vericar si los tornillos están bien apretados luego del primer uso y periódicamente en lo consiguiente para

asegurar una jación del sistema de barra aerodinámica.

Herramientas y materiales necesarios: llave Allen de 4 mm, llave Allen de 5 mm y llave dinamométrica (pulg-lbs/Nm)

Las áreas roscadas han sido previamente tratadas por Prole Design durante la producción con un compuesto especial azul para sellado de roscas. Este compuesto especial es fácil

de detectar en las roscas de todos los tornillos proporcionados. Si usted no puede detectar este compuesto de sellado de roscas o si lo ha borrado por un mantenimiento regular,

vuelva a aplicar un compuesto azul de sellado de roscas apropiado disponible a la venta por Loctite u otra compañía antes de armarlo.

Outils et éléments requis : Clé Allen 4 mm, Clé Allen 5 mm et clé dynamométrique (po-lb/Nm)

Les zones letées ont été pré-traitées par Prole Design pendant la production avec un composé frein-let bleu spécial. Ce composé spécial est facile à détecter sur les lets de

tous les boulons fournis. Si vous ne pouvez pas détecter ce composé frein-let ou si vous l’avez enlevé pendant la maintenance normale, ré-appliquez un composé frein-let bleu

approprié, disponible auprès de Loctite ou d’un autre fournisseur avant l’assemblage.

• No seguir estas advertencias e instrucciones puede resultar en una rotura, deslizamiento y u otro mal funcionamiento

de este componente de Prole Design, lo que podría causar una pérdida de control de la bicicleta con daños graves.

[AP1100-1-1]

• Un componente que rechina puede ser un signo de problemas potenciales. Asegúrese que todas las supercies de

contacto entre los componentes estén limpias, que todas las roscas de los tornillos estén engrasadas o estén tratadas

con un sello de rosca apropiado y estén ajustadas según las especicaciones de Prole Design (o del fabricante

de la bicicleta) y que todos los componentes tengan el tamaño apropiado para adaptarse entre ellos. Si continúa

experimentando un rechinamiento deje de utilizar el componente de Prole Design y llame a servicio al cliente de

Prole Design. [AP0601-2-2]

• No apretar sucientemente un tornillo puede resultar en que una parte se aoje al montar y un tornillo excesivamente

apretado puede romper inesperadamente o estropear las roscas de engranaje al montar, lo que podría derivar

también en una pérdida del control. Todos los tornillos deben ajustarse de acuerdo a las especicaciones de torsión

de Prole Design (o del fabricante de la bicicleta). En el primer ensamblaje y cualquier ensamblaje subsiguiente,

verifique si hay roscas estropeadas o rajaduras en todas las roscas macho y hembras y alguna lubricación o

compuesto de sellado de rosca necesario. [AP1100-3-2]

• Examine periódicamente y de cerca todas las supercies de este componente de Prole Design (luego de limpiar)

contra la luz del sol para vericar si hay algún trazo no pequeño o fatiga en los "puntos de tensión" (como por

ejemplo soldaduras, junturas, agujeros, puntos de contacto con otras partes, etc.). Si usted ve alguna rajadura,

no importa que tan pequeño, deje de utilizar la parte inmediatamente y llame a servicio al cliente de Prole Design.

[AP0302-4-2]

• Siempre que instale algún nuevo componente en su bicicleta, asegúrese de probarlo detenidamente cerca de casa (con

su casco) en donde no haya obstáculos o tráco. Asegúrese de que todo esté funcionando apropiadamente antes de

salir a un paseo o a una carrera. [AP1100-5-1]

• Las carreras (de caminos, montañas o deportes múltiples) imponen una tensión extrema en las bicicletas y sus

componentes (así como también en los ciclistas) y acorta signicativamente su vida útil. Si participa en estos tipos de

eventos, el ciclo de vida del producto puede acortarse significativamente dependiendo del nivel y cantidad de

carreras. El "desgaste normal" de un componente puede diferir considerablemente entre usos competitivos y usos no

competitivos, y es por ello que los ciclistas de nivel profesional utilizan bicicletas y componentes nuevos cada

temporada así como también hacen que sus bicicletas sean mantenidas por mecánicos profesionales. Se debe tener

un especial cuidado en la evaluación regular de su bicicleta y sus componentes para asegurar su seguridad. [AP1100-6-1]

• Ciertos factores pueden reducir la vida de este componente a un tiempo menor a su período de garantía. El tamaño

del ciclista y/o fortaleza y estilo al andar, una gran cantidad de millas, terrenos duros, abuso, instalación inapropiada,

sudor, condiciones medioambientales adversas (como por ejemplo aire salino o lluvia corrosiva), daños en viajes

(especialmente si la bicicleta y los componentes se desarman y vuelven a armar repetidamente) y los choques o

accidentes pueden todos contribuir a acortar la vida de este componente. Mientras más factores estén presentes, más

se reduce la vida del componente. [AP0801-7-2]

• Asegúrese que el diámetro del área de aanzamiento del manubrio coincida con el diámetro de la abrazadera del

vástago (por ejemplo, 31,8 mm, 26,0 mm o 25,4 mm). Una coincidencia incorrecta podría resultar en un daño,

deslizamiento o rotura del manubrio y o del vástago, lo que podría causar una posible pérdida de control y daño.

[B0706-4-1]

• Los manubrios de bra de carbón exigen una atención y mantenimiento especial. Para la instalación de un vástago

con manubrios de bra de carbón reérase a las instrucciones del fabricante de los manubrios antes de la instalación.

[ST1100-1-1]

• Asegúrese de volver a vericar periódicamente la abrazadera posterior (jada al trinche) y la abrazadera delantera

(jada al manubrio) el ajuste del tornillo hexagonal (especialmente luego de montar en terrenos accidentados) para

asegurar una buena jación. [ST1100-2-1]

• Los trinches con tubos de dirección de bra de carbón exigen una atención y mantenimiento especial. Reérase a las

instrucciones del fabricante del trinche.

[ST1100-5-1]

4. Ajuste la rotación y la longitud de la extensión aojando el perno M6 que asegura a la extensión.

Una vez que se logre la rotación y longitud deseadas, apriete el perno M6 en 6 Nm (53 pulg-lbs).

• Prole Design garantiza todos sus productos durante dos años desde la compra original.

• Para mayores detalles sobre la garantía de Prole Design y la política de Reemplazo por accidentes,

visite www.prole-design.com/warranty

• Any failure to follow these warnings and instructions can result in breakage, slippage and or other malfunctioning of

this Prole Design component causing a loss of control of the bicycle with serious injuries. [AP1100-1-1]

• A creaking component can be a sign of potential problems. Make sure all contact surfaces between components are

clean, all bolt threads are greased or are treated with proper thread lock and tightened to Prole Design's (or the bike

manufacturers) specications and all components are properly sized to t together. If you continue to experience

creaking stop using the Prole Design component and call Prole Design customer service. [AP0601-2-2]

• Under tightening a bolt can result in a part coming loose while riding and an over tightened bolt can break

unexpectedly or strip the threads it is engaging while riding also resulting in a loss of control. All bolts must be

tightened to Profile Design's (or the bike manufacturer's) torque specifications. On the first and any subsequent

assembly examine all male and female threads and bolts for stripped threads, cracks and any required lubrication or

thread locking compound. [AP1100-3-2]

• Periodically, closely examine all surfaces of this Prole Design component (after cleaning) in bright sunlight to check

for any small hairline cracks or fatigue at "stress points" (such as welds, seams, holes, points of contact with other

parts etc.). If you see any cracks, no matter how small, stop using the part immediately and call Profile Design

customer service. [AP0302-4-2]

• Whenever you install any new component on your bike make sure you thoroughly try it out close to home (with your

helmet) where there are no obstacles or trafc. Make sure everything is working properly before going off on a ride or

to a race. [AP1100-5-1]

• Racing (road, mountain or multi-sport) places extreme stress on bicycles and their components (like it does riders) and

signicantly shortens their usable life. If you participate in these types of events, the lifetime of the product may be

signicantly shortened depending upon the level and amount of racing. The “normal wear” of a component may differ

greatly between competitive and non-competitive uses, which is why professional level riders often use new bikes and

components each season as well as having their bikes serviced by professional mechanics. Particular care should be

placed in the regular examination of your bicycle and it’s components to insure your safety. [AP1100-6-1]

• A number of factors can reduce the life of this component to less than its warranty period. Rider size and/or strength

and riding style, high mileage, rough terrain, abuse, improper installation, sweat, adverse environmental conditions (such

as salt air or corrosive rain), travel damage (especially if bike and components are repeatedly disassembled and then

reassembled) and crashes or accidents can all contribute to the shortening of the life of this component. The more

factors that are present, the more the life of the component is reduced. [AP0801-7-2]

• Make sure the handlebar clamp area diameter matches that of the stem clamp diameter (i.e. 31.8mm, 26.0mm or

25.4mm). An incorrect match could result in handlebar and or stem damage, slippage or breakage causing a possible

loss of control and injury. [B0706-4-1]

• Carbon fiber handlebars require special attention and maintenance. For installation of a stem with carbon fiber

handlebars please refer to handlebar manufacturer’s instructions prior to installation. [ST1100-1-1]

• Make sure you periodically recheck rear clamp (fork attachment) and front clamp (handlebar attachment) stem bolt

tightness (especially after riding on rough terrain) to insure a good attachment. [ST1100-2-1]

• Forks with carbon fiber steering tubes require special attention and maintenance. Refer to fork manufacturer’s

instructions. [ST1100-5-1]

• Prole Design gewährt auf sämtliche Produkte eine zweijährige Garantie ab Kaufdatum.

• Detaillierte Angaben zur Prole Design-Garantie und zum Austausch bei Stürzen/Unfällen

nden Sie hier: www.prole-design.com/warranty

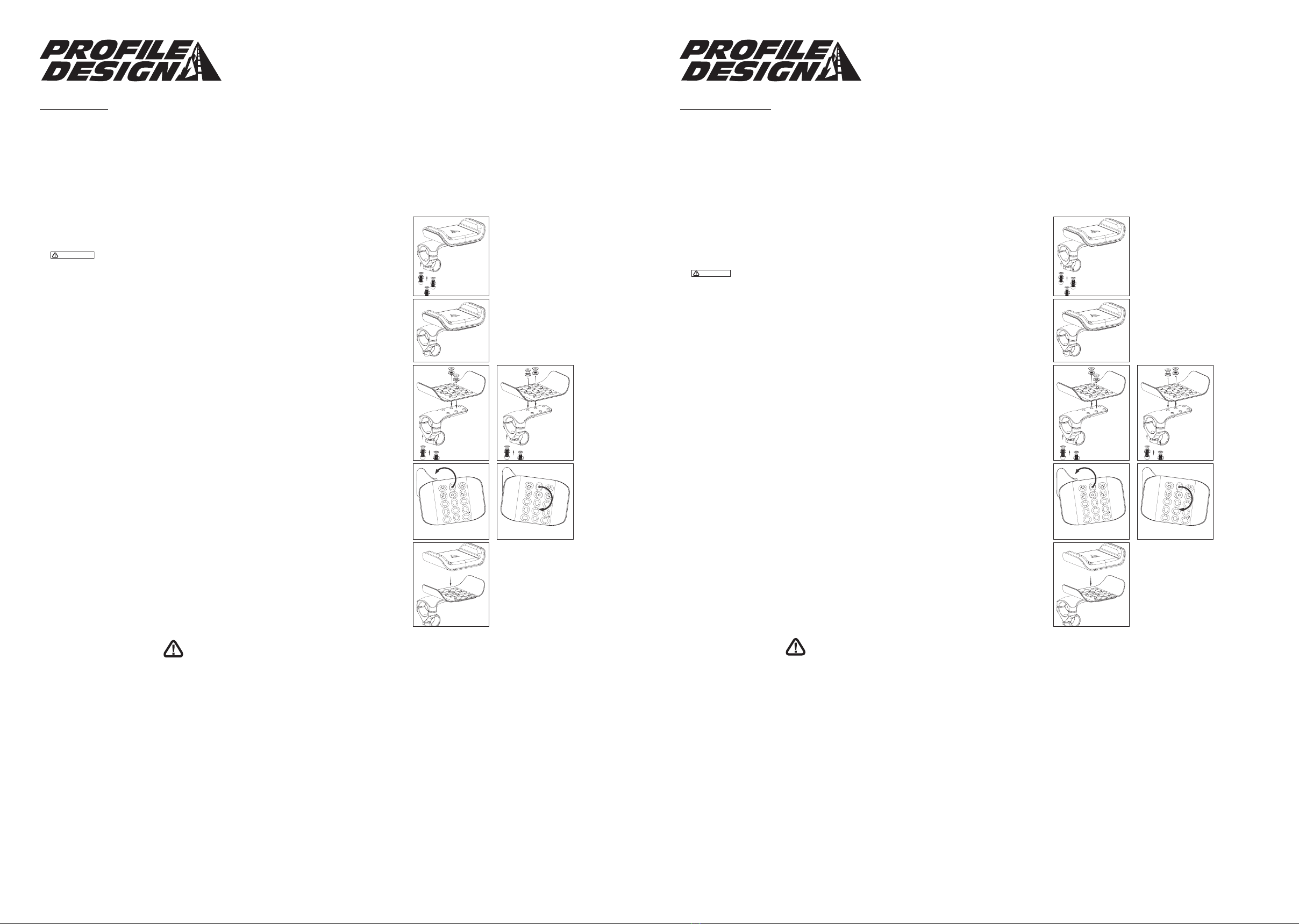

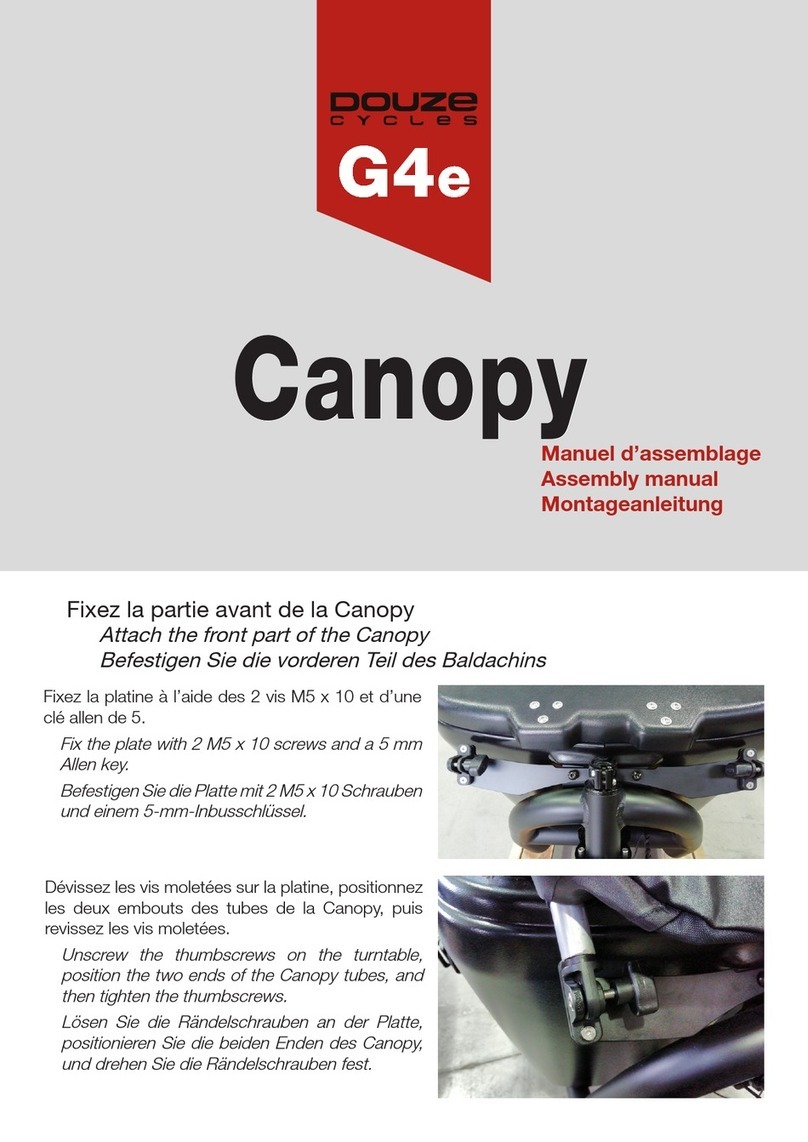

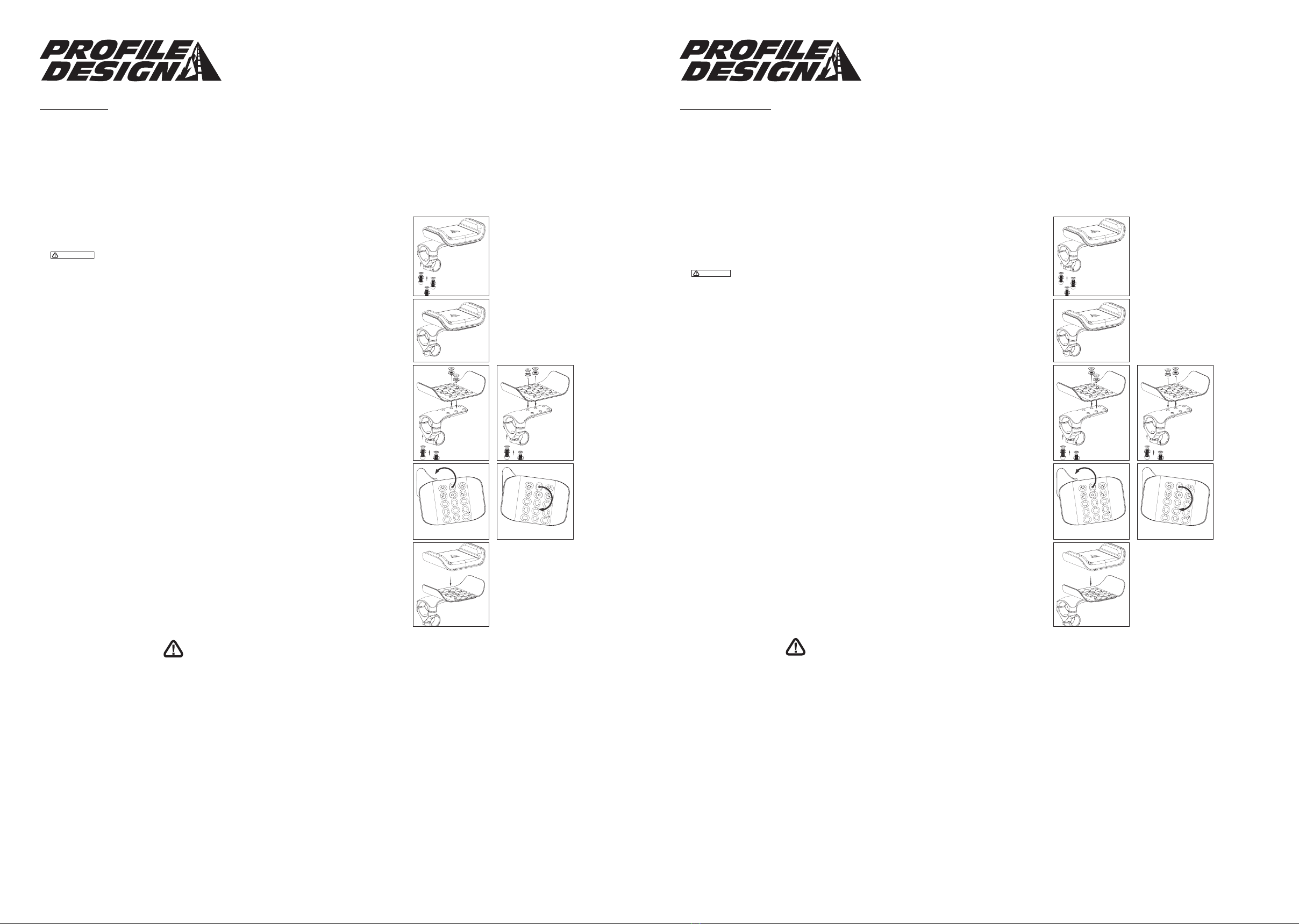

1. Retirez les boulons M6 de la partie inférieure de l’attache.

2. Placez le support sur le cintre et connectez le support en U de la partie inférieure au support du prolongateur de guidon.

Vissez les boulons à la main.

3. Ajustez la largeur et l’inclinaison du cintre à la position souhaitée. Serrez uniformément les boulons M6 à 6 Nm (53 po.lb)

Ne faites pas passer les câbles des freins ou du dérailleur entre le support du prolongateur de

guidon et le cintre de base.

5. Placez le repose-bras en position préférentielle sur le support. Insérez le boulon M6 par le repose-bras et dans le support.

À l’aide de la clé Allen 4 mm, vissez le boulon jusqu’à ce qu’il soit bien serré. Répétez l’opération pour le deuxième boulon

en le laissant légèrement desserré pour permettre l’ajustement.

REMARQUE: Les boulons peuvent être installés côte à côte ou d’avant en arrière pour un positionnement

optimisé du repose-bras.

6. Faites pivoter le repose-bras jusqu’à l’angle préférentiel par rapport à l’extension.

Serrez uniformément à 4,7 Nm (42 po.lbs).

7. Appuyez le rembourrage contre le repose-bras et tenez-le fermement pendant 30 secondes. Répétez l’opération pour

l’autre repose-bras.

8. Vériez à nouveau le serrage des boulons après la première utilisation et périodiquement ensuite pour vous assurer de la

xation solide du système prolongateur de guidon.

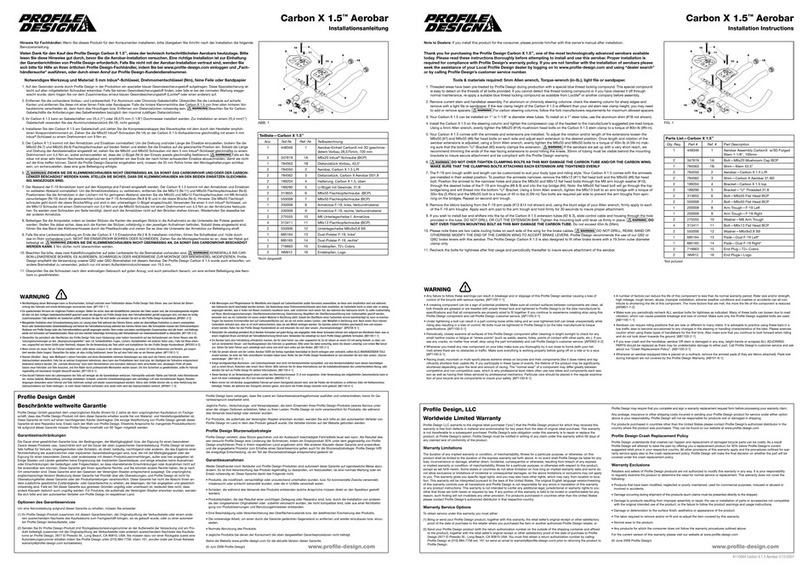

1.、2.、3.1.、2.、3.

7.、8.7.、8.

4.4.

5.5.

6.6.

4. Ajustez la rotation et la longueur de l’extension en desserrant le boulon M6 xant l’extension.

Une fois la rotation et la longueur souhaitées déterminées, serrez le boulon M6 à 6 Nm (53 po.lb).