INSTRUCTION

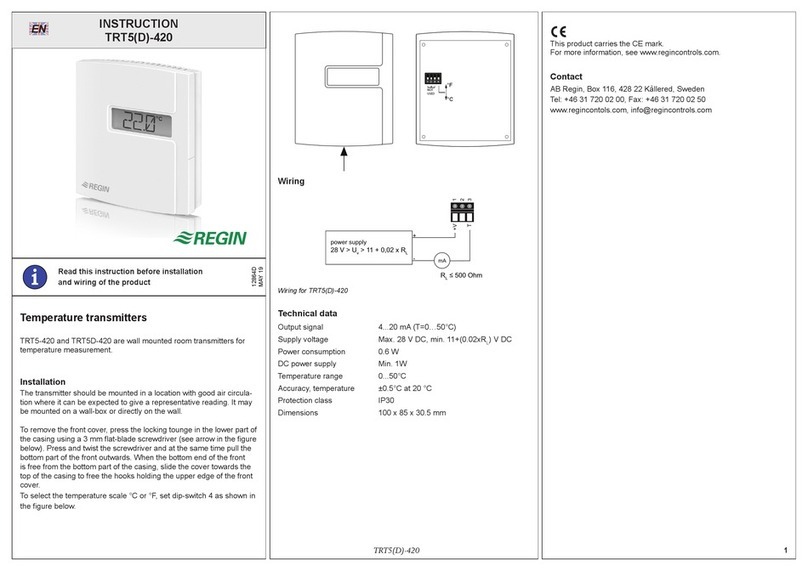

Read this instruction before installation

and wiring of the product

Presigo PDT...C(-2) 1

Presigo PDT...C(-2)

Pressure transmitter

Presigo PDT...(-2) is a range of pressure transmitters with one or

two pressure sensors, two universal inputs and an RS485 port for

data exchange. The RS485 port can be easily configured for either

EXOline or Modbus communication. The transmitter can be used as a

slave unit in an EXOline or Modbus system.

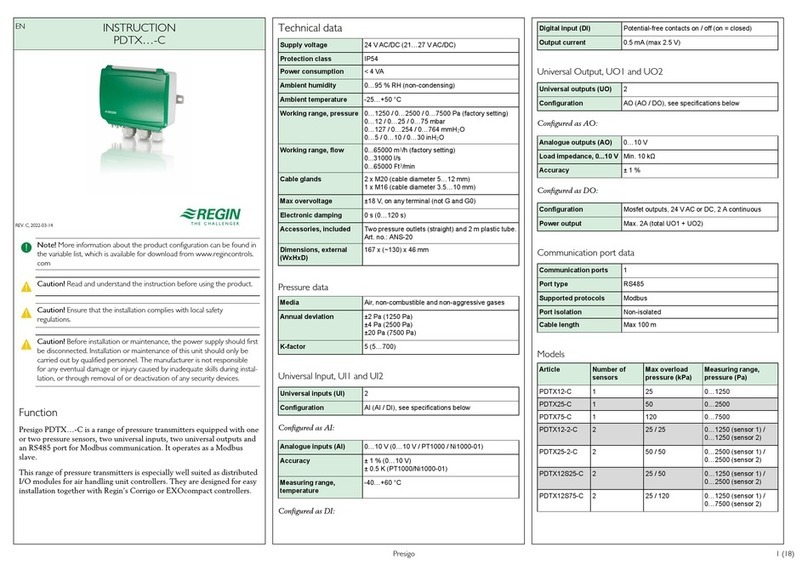

Technical data

Supply voltage 24 V AC/DC ±15 %

Protection class IP54

Calculated power consumption 2 VA (rms).

Minimum trafo size 7.5 VA.

Data transmission channel Non-isolated RS485 (max. 100 m)

Overall accuracy, pressure ≤1 % full scale

Annual deviation (typical)

P1250 models ±2 Pa

P2500 models ±4 Pa

P7500 models ±20 Pa

Damping (settable) 1…12 s

K-factor (settable) 5…700

Operating temperature range -25...+50°C

Operating humidity Max.95 % RH (non-condensing)

Accessories, included Two pressure outlets (straight) and

2 m plastic tube. Art. no.: ANS-20

Overvoltage on any terminal Max. ±18 V (referenced to GND)

Pressure data, Media Air, non-combustable and non-aggres

sive gases

Universal inputs UI1, UI2

Configured as Ambient

temperature

Accuracy Range

PT1000* -25...0°C ±1 K -40...+60°C alt.

-40...140°F

0...50°C ±0.5 K

Ni1000; 6180 ppm/K -25...0°C ±1 K -40...+60°C alt.

-40...140°F

0...50°C ±0.5 K

0...10 V - ± 1 % full

scale

-

Digital input Potential-free contacts on/off(closed=on)

* Factory setting

Pressure ranges (full scale)

Model Pa (factory

setting)

mBar mmH2O inH2O

PDT12C PS1 0…1250 0…12.5 0…125 0…5

PDT25C PS1 0…2500 0…25 0…250 0…10

PDT75C PS1 0…7500 0…75 0…750 0…30

PDT12C-2 PS1 0…1250 0…12.5 0…125 0…5

PS2 0…1250 0…12.5 0…125 0…5

PDT12S25C-2 PS1 0…1250 0…12.5 0…125 0…5

PS2 0…2500 0…25 0…250 0…10

PDT25C-2 PS1 0…2500 0…25 0…250 0…10

PS2 0…2500 0…25 0…250 0…10

PDT12S75C-2 PS1 0…1250 0…12.5 0…125 0…5

PS2 0…7500 0…75 0…750 0…30

NOTE: The suffix in the name denotes the number of sensors in the unit:

• No suffix: One sensor (only PS1 is present, reading PS2 related

parameters will yield a zero value reading).

• -2: Two sensors

The “S” in the name denotes split/different sensor ranges for PS1 and

PS2.

Flow settings

The following flow ranges apply when selecting a unit of measure-

ment for flow measurement:

Unit Flow ranges (full scale)

l/s 0…31000

m3/h (factory setting) 0…65000

CFM [Ft3/min] 0…65000

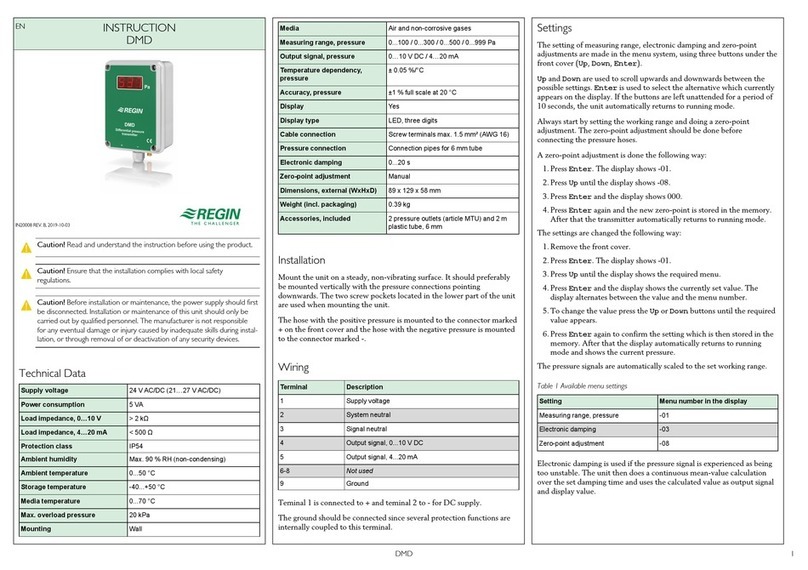

Installation

NOTE: Use a shielded, twisted pair cable for RS485 communication.

At high risks of interference, a 120 Ωterminating resistor should be

mounted at each end of the communications circuit.

1. Mount the transmitter horizontally or vertically on a stable,

vibration-free surface. If the unit is installed in a humid environ-

ment, install it vertically with the cable gland edge of the unit

pointing down to allow moisture to escape.

2. Refer to the graphics below for wiring. Connect the communica-

tion cable to terminals 3(B) and 4(A). Use the leftmost cable

gland for supply voltage and communication. Use the rightmost

cable gland for the universal inputs.

3. Set the DIP-switches to the desired operating mode and param-

eters. DIP-switch 6 can be used to offset the ELA address to

allow setting up two units at the same time. The transmitter uses

the address 1 as a default address for Modbus. For EXOline,

dual sensor transmitters use 242:1 as default address and single

sensor transmitters use 242:3 as their default address.

4. Power up the unit. Refer to the variable list in the Presigo

PDT...C(-2) manual for information on how to access transmitter

data.

5. Let the unit warm up for 10 minutes, then perform a zero-set

calibration by pressing the pushbutton.

6. Connect plastic tubes from the ventilation duct to the pressure

inlets.

NOTE: A straight cut offnipple must be used for mounting in the

ventilation duct.

For optimal measuring results, measuring points with turbulent

air flow should be avoided. Preferably, measuring should be

performed at a distance of 2 duct diameters before bends and

11799H

AUG 23

EN