RIGHT ANGLE 4 Vuelta Series User manual

Other RIGHT ANGLE Indoor Furnishing manuals

RIGHT ANGLE

RIGHT ANGLE Hover Helium Junior User manual

RIGHT ANGLE

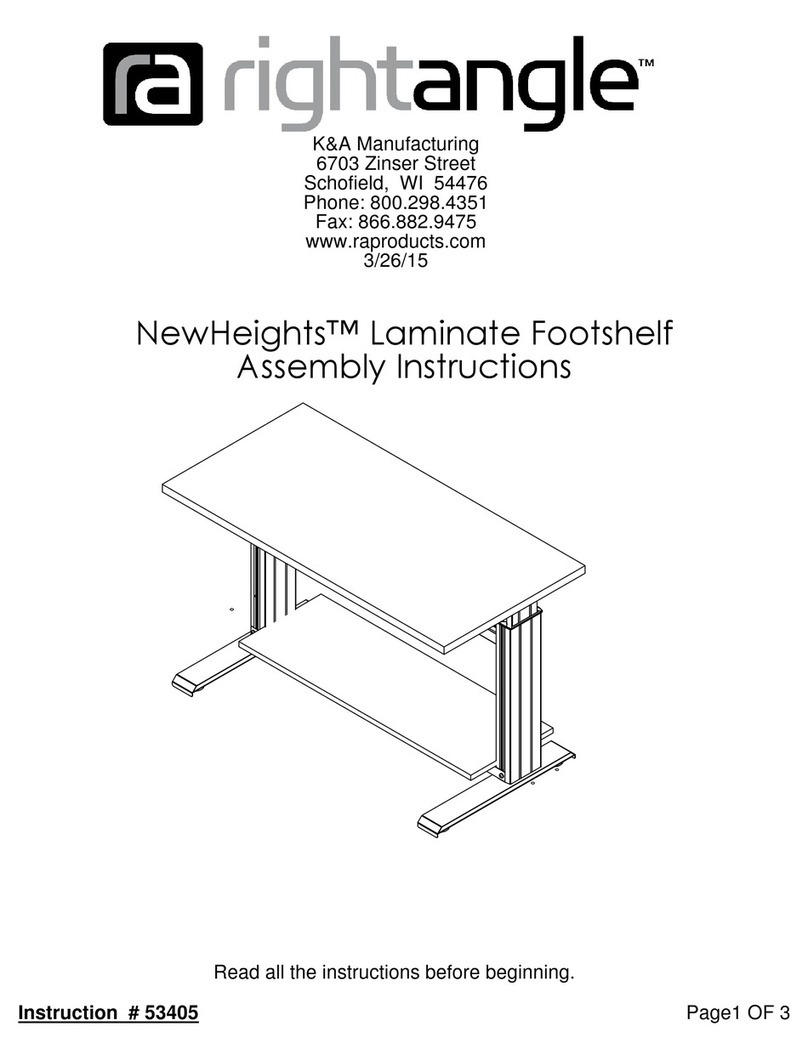

RIGHT ANGLE NewHeights Laminate Footshelf User manual

RIGHT ANGLE

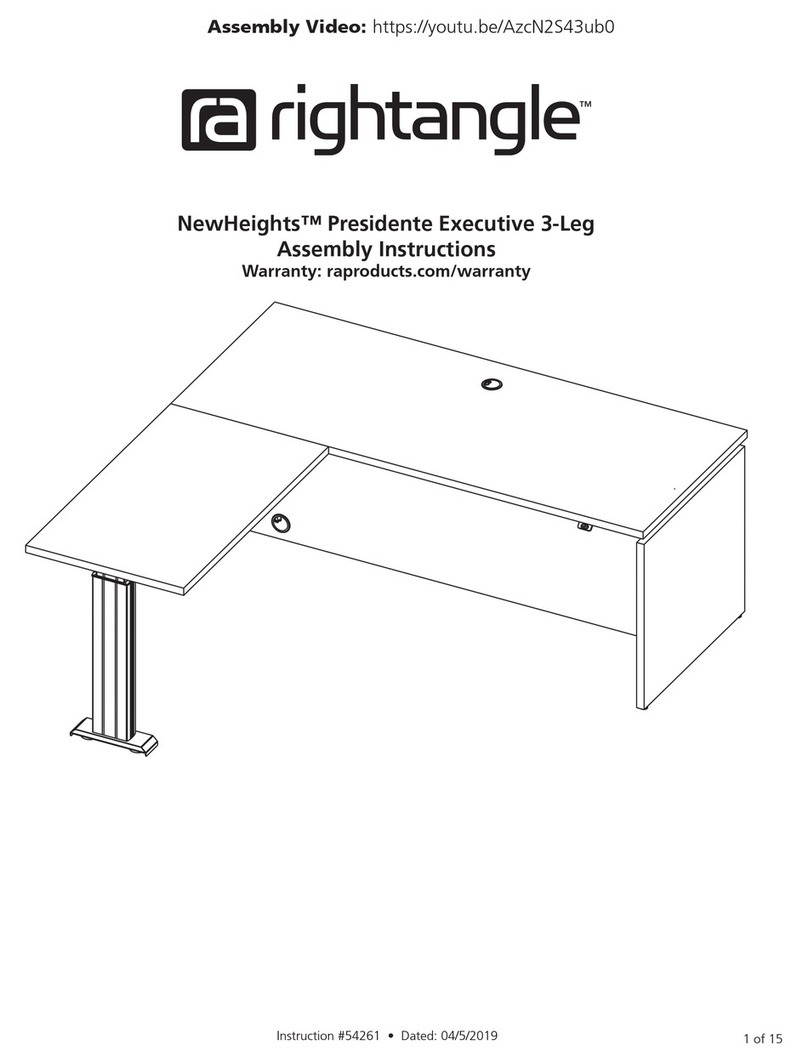

RIGHT ANGLE NewHeights Presidente User manual

RIGHT ANGLE

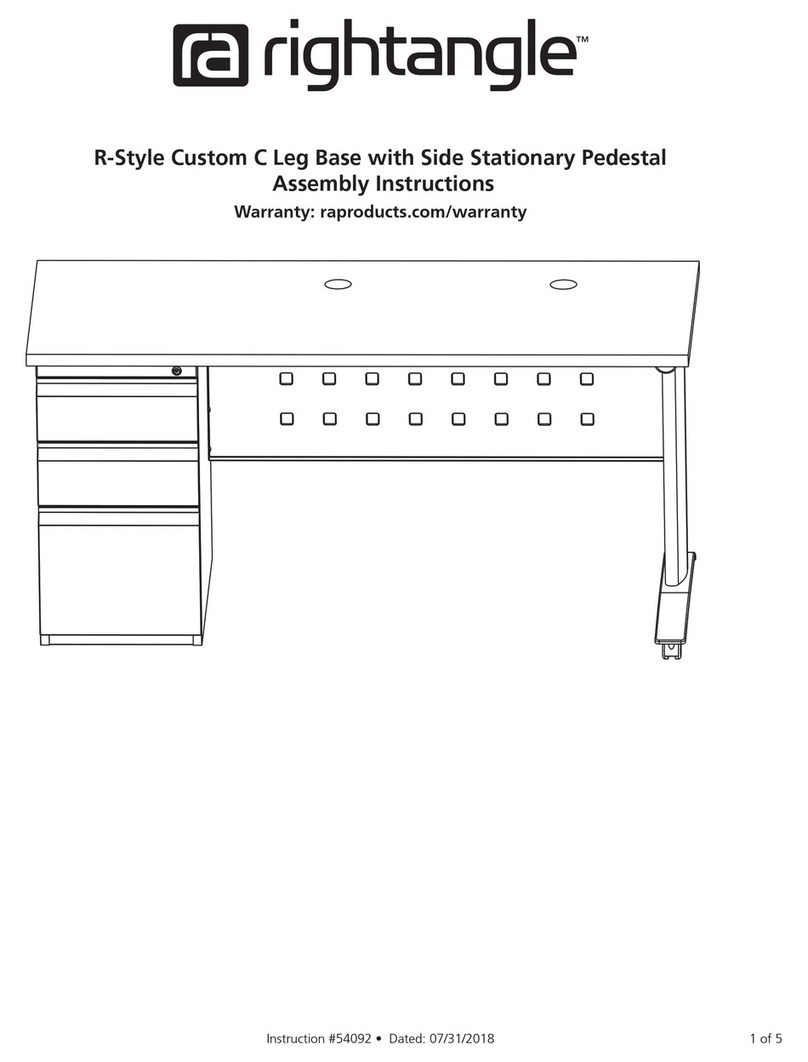

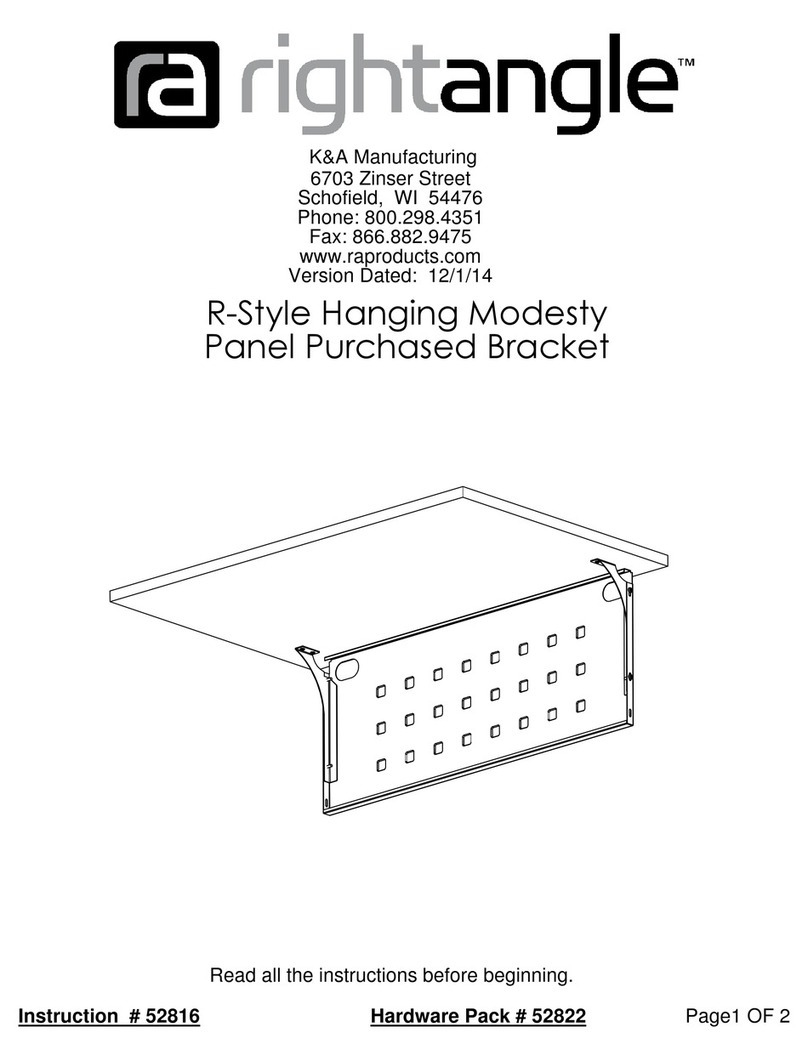

RIGHT ANGLE R-Style 52822 User manual

RIGHT ANGLE

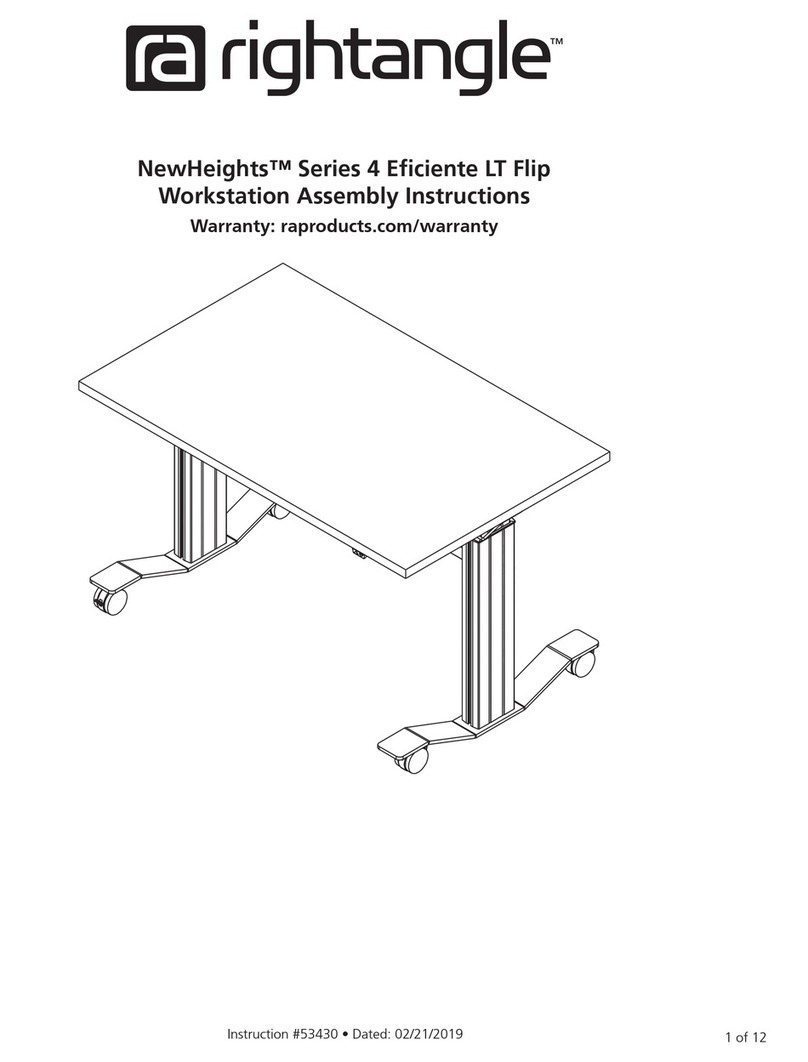

RIGHT ANGLE NewHeights 4 NZP Series User manual

RIGHT ANGLE

RIGHT ANGLE R-Style Tango User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights 4 Series User manual

RIGHT ANGLE

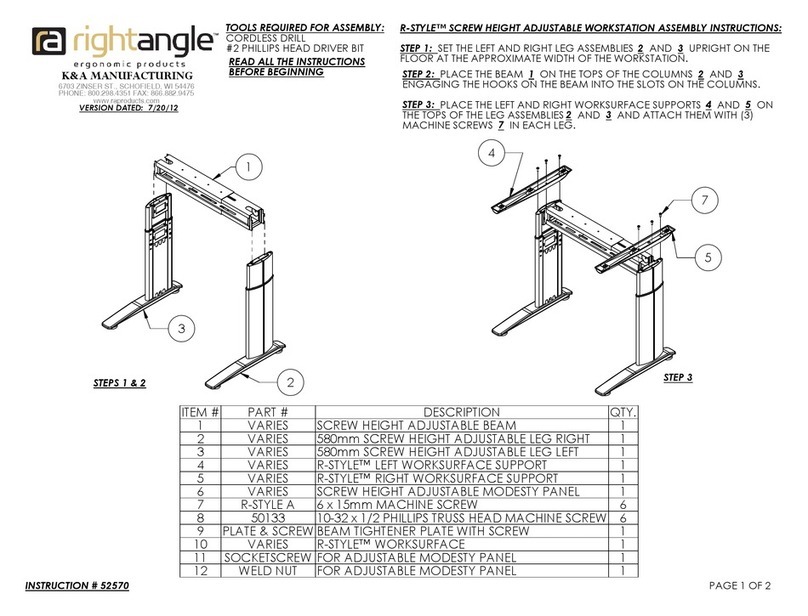

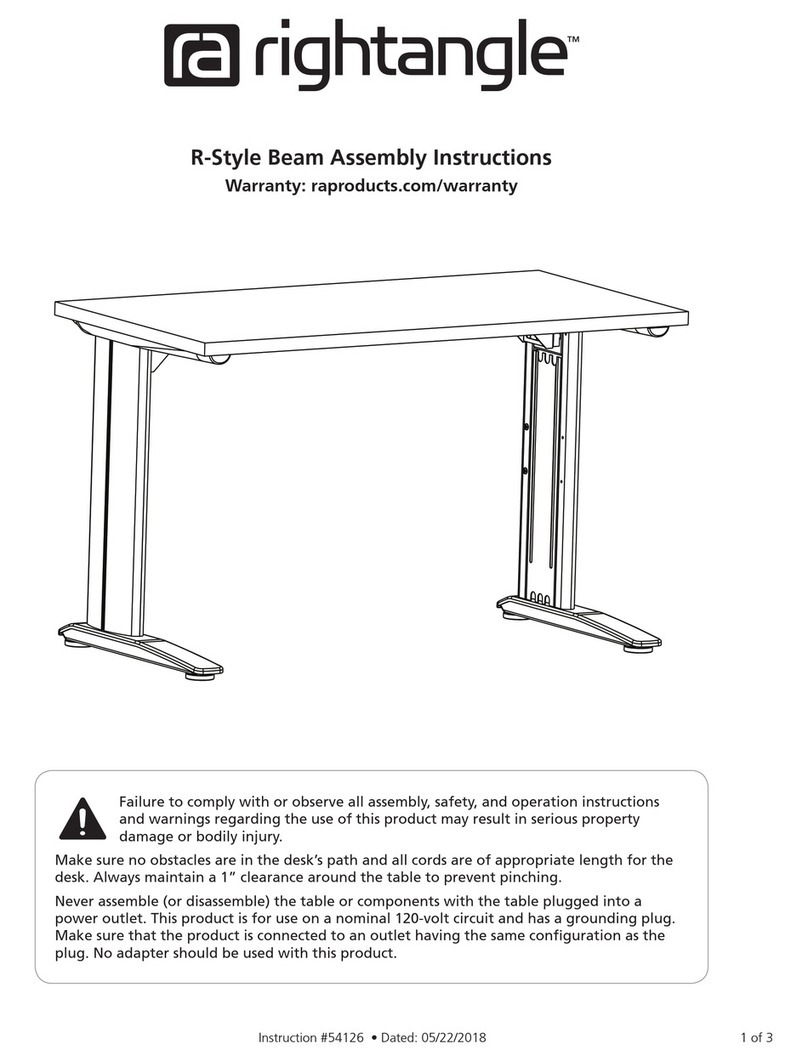

RIGHT ANGLE R-Style Beam User manual

RIGHT ANGLE

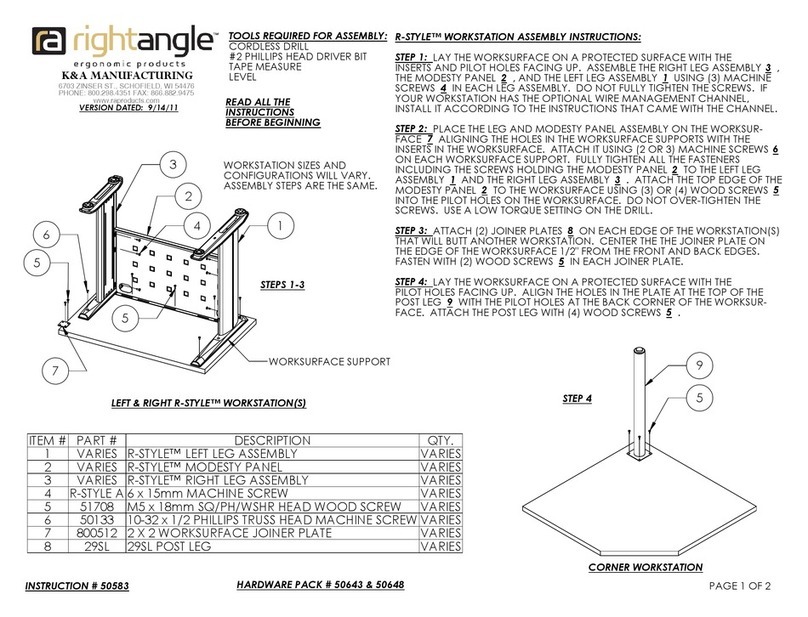

RIGHT ANGLE R-STYLE WORKSTATION 50643 User manual

RIGHT ANGLE

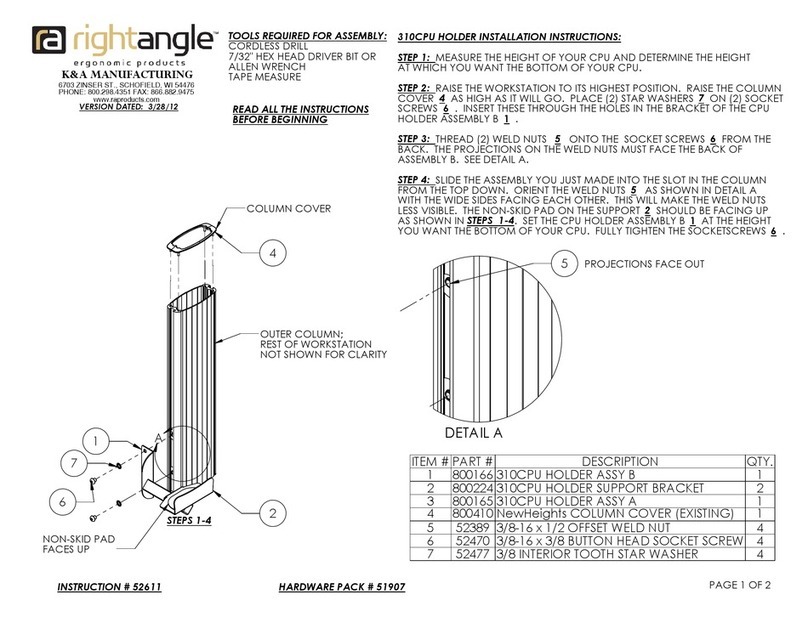

RIGHT ANGLE 310CPU User manual

RIGHT ANGLE

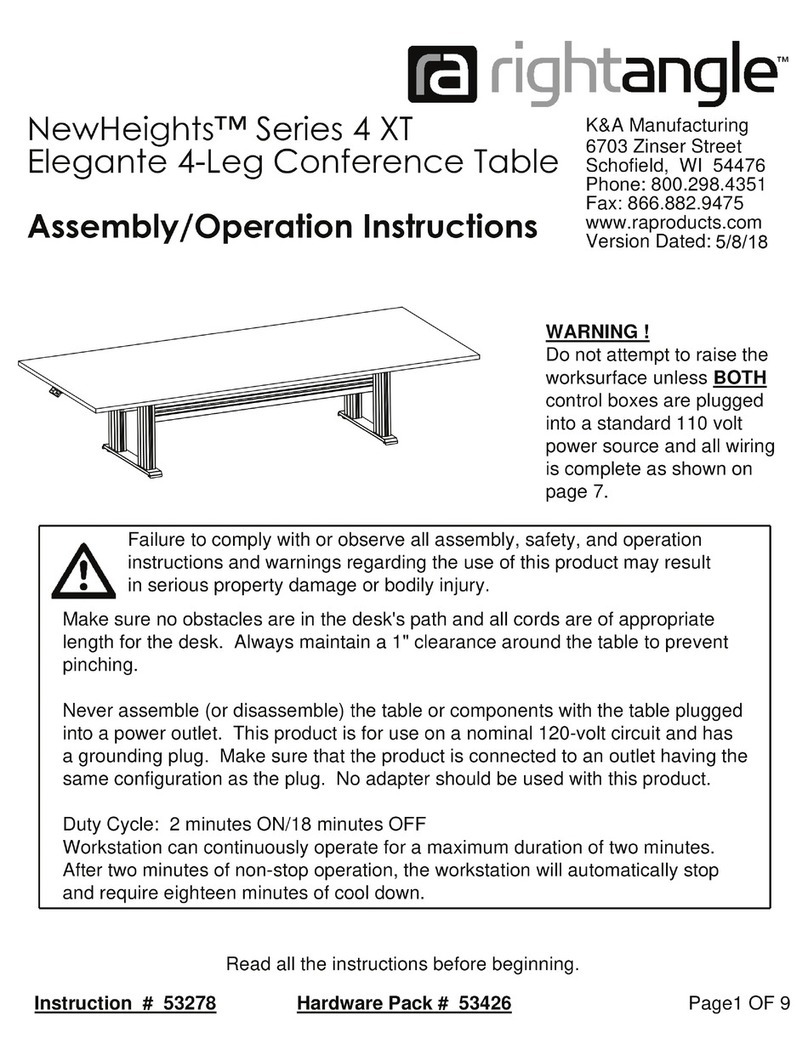

RIGHT ANGLE NewHeights 4 XT Series Parts list manual

RIGHT ANGLE

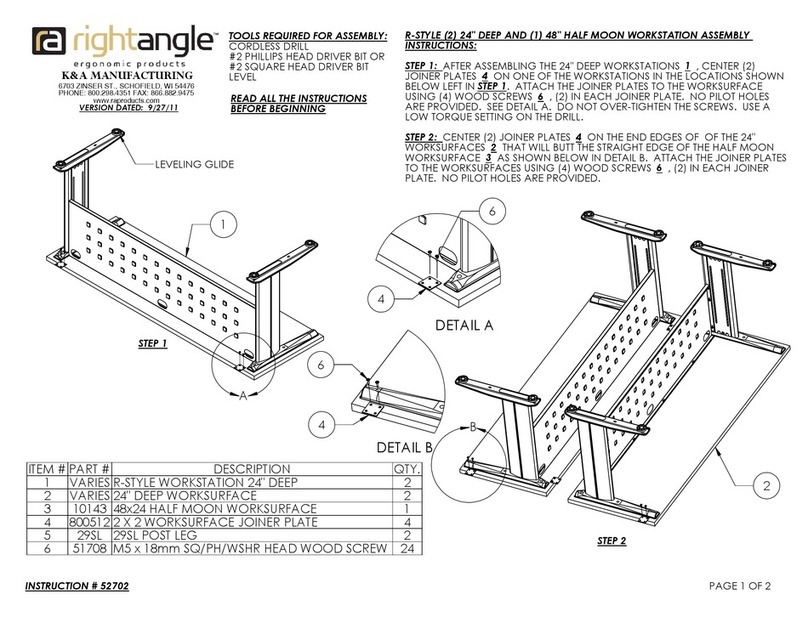

RIGHT ANGLE 48 HALF MOON ON R-STYLE User manual

RIGHT ANGLE

RIGHT ANGLE NEWHEIGHTS Series 4 XT Parts list manual

RIGHT ANGLE

RIGHT ANGLE NewHeights Series User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights 4 LT Series User manual

RIGHT ANGLE

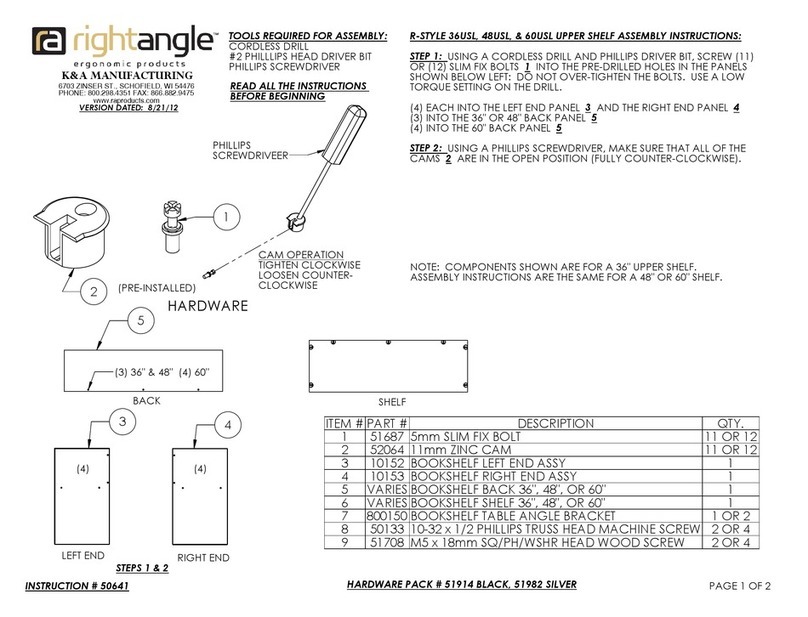

RIGHT ANGLE R-STYLE 36USL User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights Series User manual

RIGHT ANGLE

RIGHT ANGLE NewHeight 4 Series User manual

RIGHT ANGLE

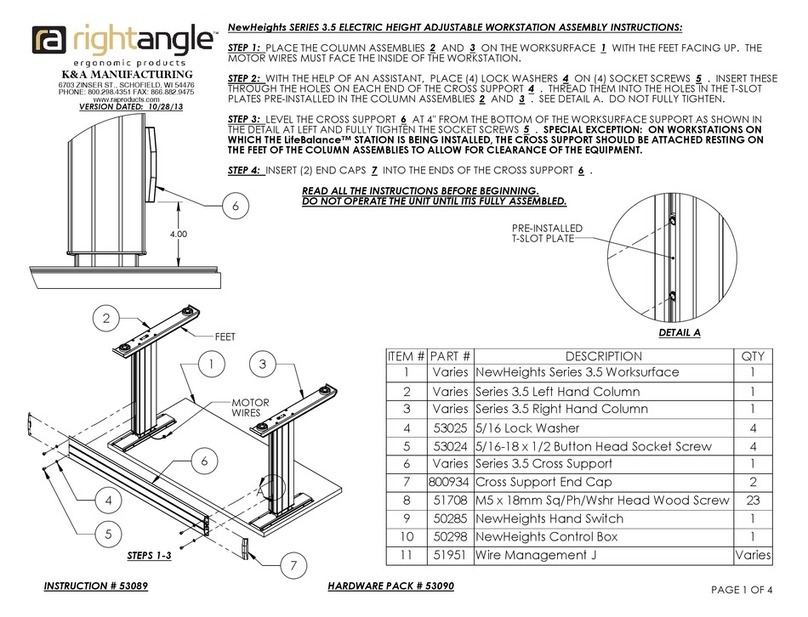

RIGHT ANGLE NewHeights Electric Height Adjustable... User manual

RIGHT ANGLE

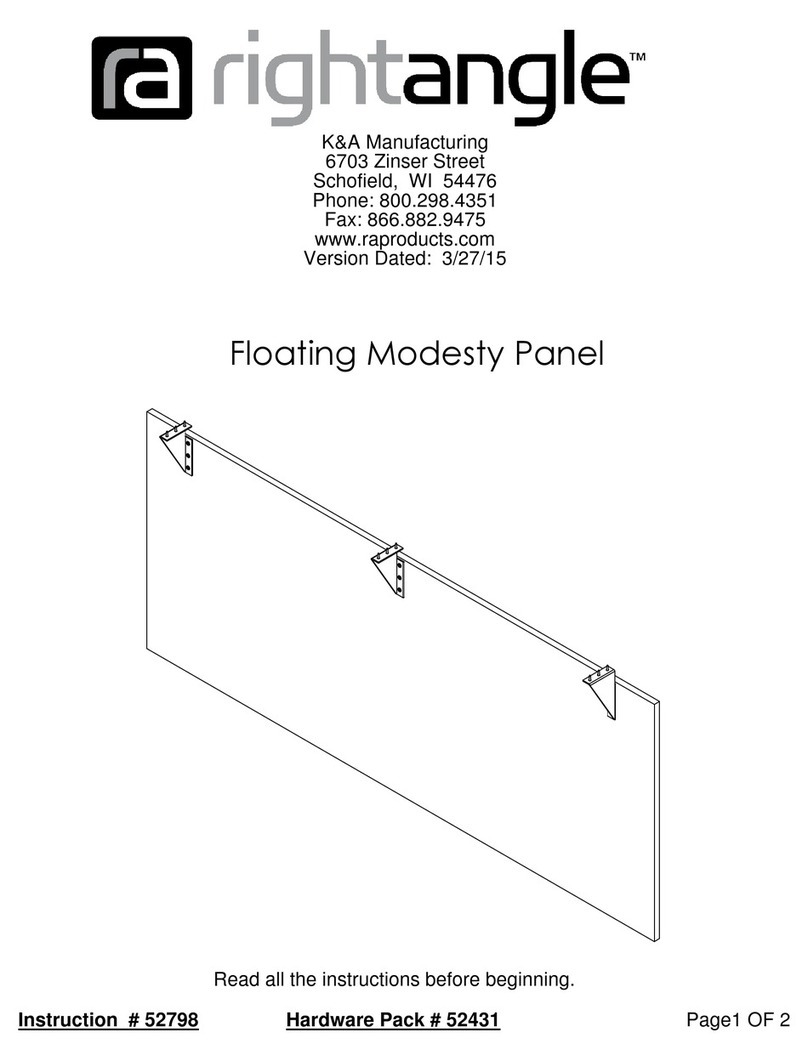

RIGHT ANGLE R-Style Modesty Panel User manual

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual