S100 Extreme InstallaonSECTION C / PART 2 WIRE GUIDE INSTALLATION Cont ... WIRE GUIDES

Page 4

iii)i) i)iv) vi)

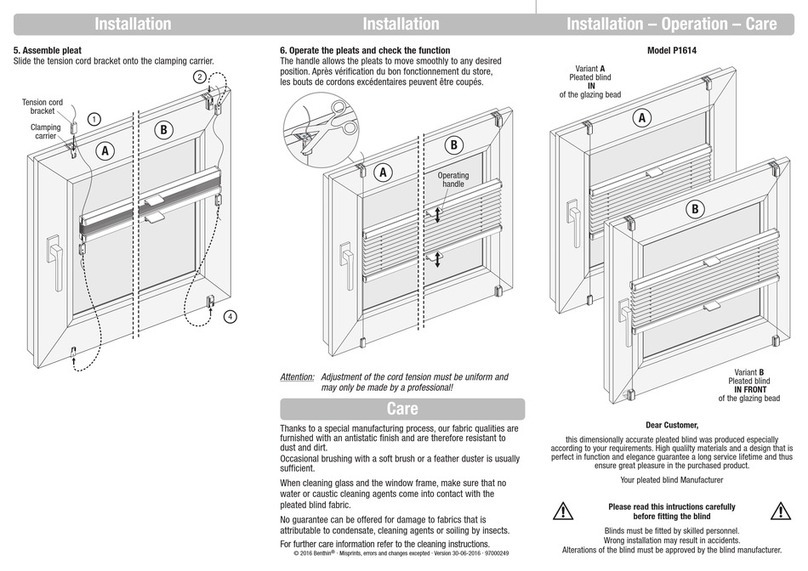

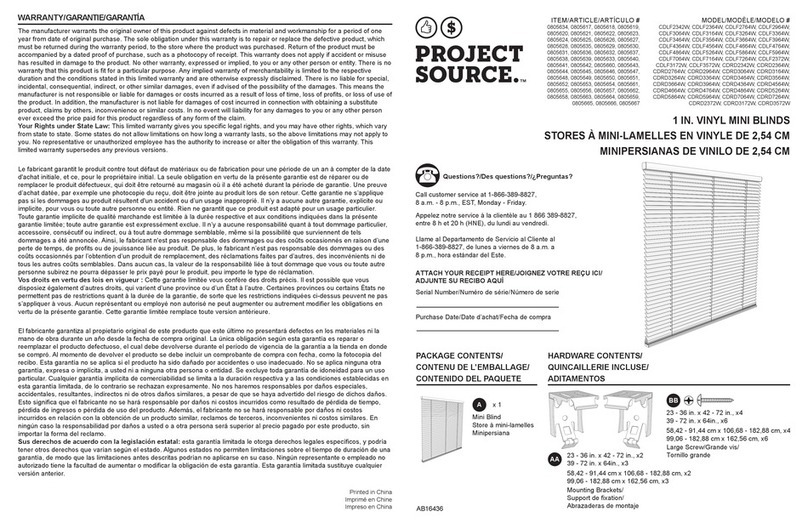

Tensioning Bracket - Floor/Side/Face Fix

Note: Refer to deducons for theorecal cable lengths. Measure, cut & crimp wire onsite to validate & ensure correct cable length.

Stud Terminal - Side/Face Fix

v)ii)

Refer

Crimp

Detail

Refer

Crimp

Detail

ii)

Refer

Swage

Detail

iii)

Refer

Crimp

Detail

Cable Length (C)

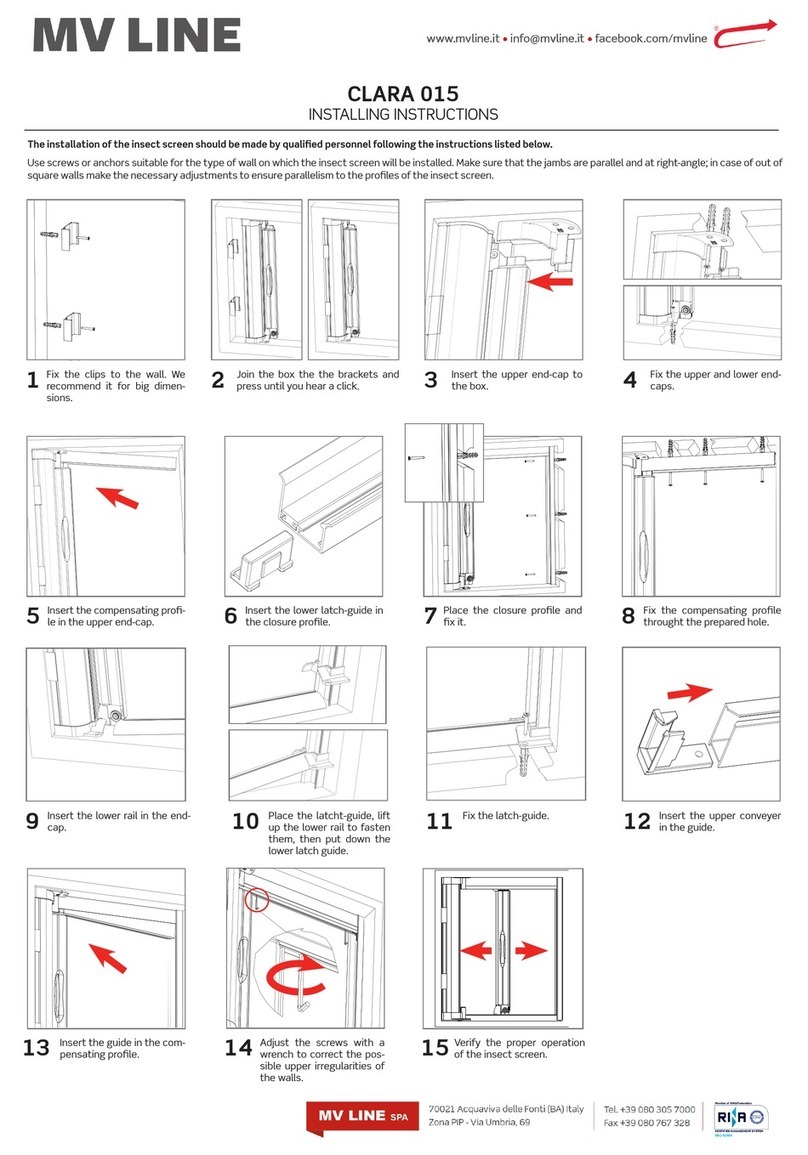

b) Ensure 2x crimps minimum per terminal. c) Minimum Crimp specificaon guide.

Minimum Crimp Specificaons

a) Ensure cable is fully inserted into terminal

Refer to table below for guide of crimp posion and sizing for all terminals.

BB

C1C2 A

NOTE: Ensure jaws of crimp tool close completely to acheive maximum

possible crimp strength - use dimension A as a guide).

Item

A (Crimp Hex AF)

B (Crimp spacing)

C1/C2 (Crimp length)

Size

(mm)

6.5

3.0

7.5

Size

(in)

0.26”

0.12”

0.30”

Note: Ensure end cap and terminal

have been inserted onto wire in the

correct order before crimping

S100 Extreme InstallaonSECTION C / PART 2 WIRE GUIDE INSTALLATION Cont ... WIRE GUIDES

Page 4

iii)i) i)iv) vi)

Tensioning Bracket - Floor/Side/Face Fix

Note: Refer to deducons for theorecal cable lengths. Measure, cut & crimp wire onsite to validate & ensure correct cable length.

Stud Terminal - Side/Face Fix

v)ii)

Refer

Crimp

Detail

Refer

Crimp

Detail

ii)

Refer

Swage

Detail

iii)

Refer

Crimp

Detail

Cable Length (C)

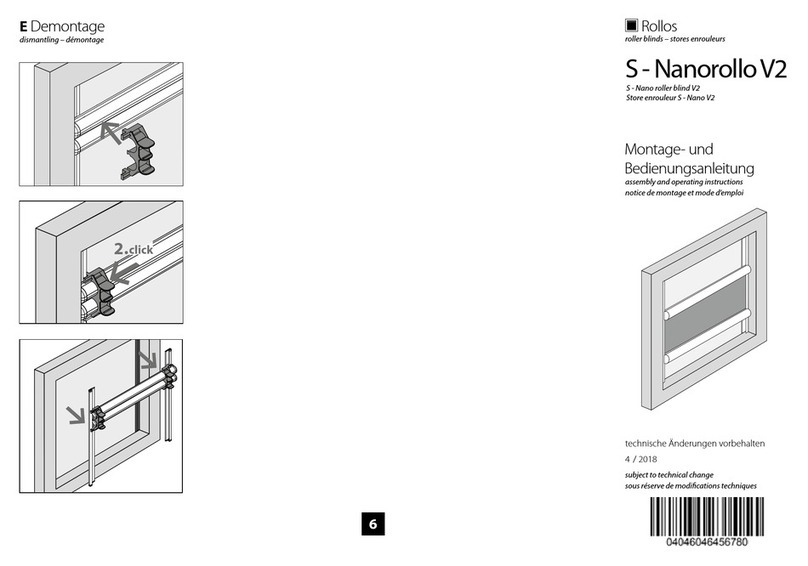

b) Ensure 2x crimps minimum per terminal. c) Minimum Crimp specificaon guide.

Minimum Crimp Specificaons

a) Ensure cable is fully inserted into terminal

Refer to table below for guide of crimp posion and sizing for all terminals.

BB

C1C2 A

NOTE: Ensure jaws of crimp tool close completely to acheive maximum

possible crimp strength - use dimension A as a guide).

Item

A (Crimp Hex AF)

B (Crimp spacing)

C1/C2 (Crimp length)

Size

(mm)

6.5

3.0

7.5

Size

(in)

0.26”

0.12”

0.30”

Note: Ensure end cap and terminal

have been inserted onto wire in the

correct order before crimping

S100 Extreme InstallaonSECTION C / PART 2 WIRE GUIDE INSTALLATION Cont ... WIRE GUIDES

Page 4

iii)i) i)iv) vi)

Tensioning Bracket - Floor/Side/Face Fix

Note: Refer to deducons for theorecal cable lengths. Measure, cut & crimp wire onsite to validate & ensure correct cable length.

Stud Terminal - Side/Face Fix

v)ii)

Refer

Crimp

Detail

Refer

Crimp

Detail

ii)

Refer

Swage

Detail

iii)

Refer

Crimp

Detail

Cable Length (C)

b) Ensure 2x crimps minimum per terminal. c) Minimum Crimp specificaon guide.

Minimum Crimp Specificaons

a) Ensure cable is fully inserted into terminal

Refer to table below for guide of crimp posion and sizing for all terminals.

BB

C1C2 A

NOTE: Ensure jaws of crimp tool close completely to acheive maximum

possible crimp strength - use dimension A as a guide).

Item

A (Crimp Hex AF)

B (Crimp spacing)

C1/C2 (Crimp length)

Size

(mm)

6.5

3.0

7.5

Size

(in)

0.26”

0.12”

0.30”

Note: Ensure end cap and terminal

have been inserted onto wire in the

correct order before crimping

S100 Extreme InstallaonSECTION C / PART 2 WIRE GUIDE INSTALLATION Cont ... WIRE GUIDES

Page 4

iii)i) i)iv) vi)

Tensioning Bracket - Floor/Side/Face Fix

Note: Refer to deducons for theorecal cable lengths. Measure, cut & crimp wire onsite to validate & ensure correct cable length.

Stud Terminal - Side/Face Fix

v)ii)

Refer

Crimp

Detail

Refer

Crimp

Detail

ii)

Refer

Swage

Detail

iii)

Refer

Crimp

Detail

Cable Length (C)

b) Ensure 2x crimps minimum per terminal. c) Minimum Crimp specificaon guide.

Minimum Crimp Specificaons

a) Ensure cable is fully inserted into terminal

Refer to table below for guide of crimp posion and sizing for all terminals.

BB

C1C2 A

NOTE: Ensure jaws of crimp tool close completely to acheive maximum

possible crimp strength - use dimension A as a guide).

Item

A (Crimp Hex AF)

B (Crimp spacing)

C1/C2 (Crimp length)

Size

(mm)

6.5

3.0

7.5

Size

(in)

0.26”

0.12”

0.30”

Note: Ensure end cap and terminal

have been inserted onto wire in the

correct order before crimping

Page. 10 EXTREME Wire Guide Installation Manual | v 3.0

2020 © Copyright All Rights Reserved Rollease Acmeda

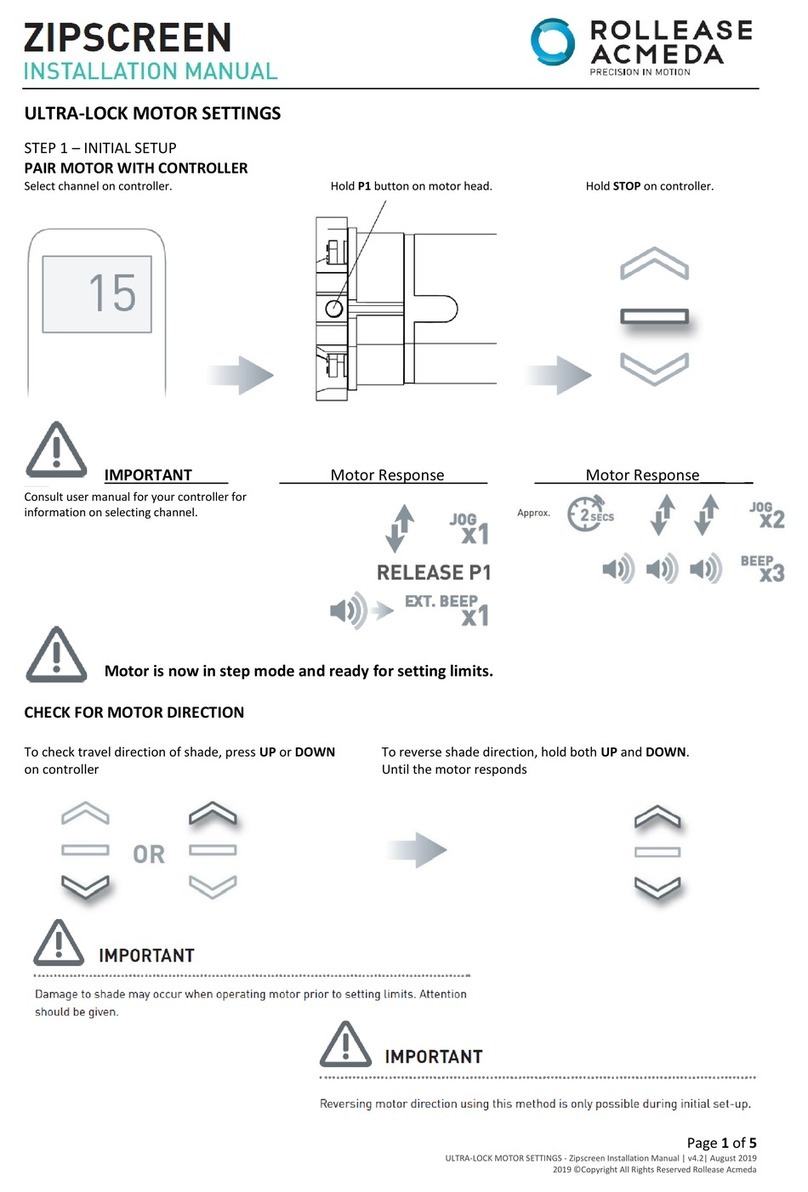

SECTION 3 | INSTALLATION

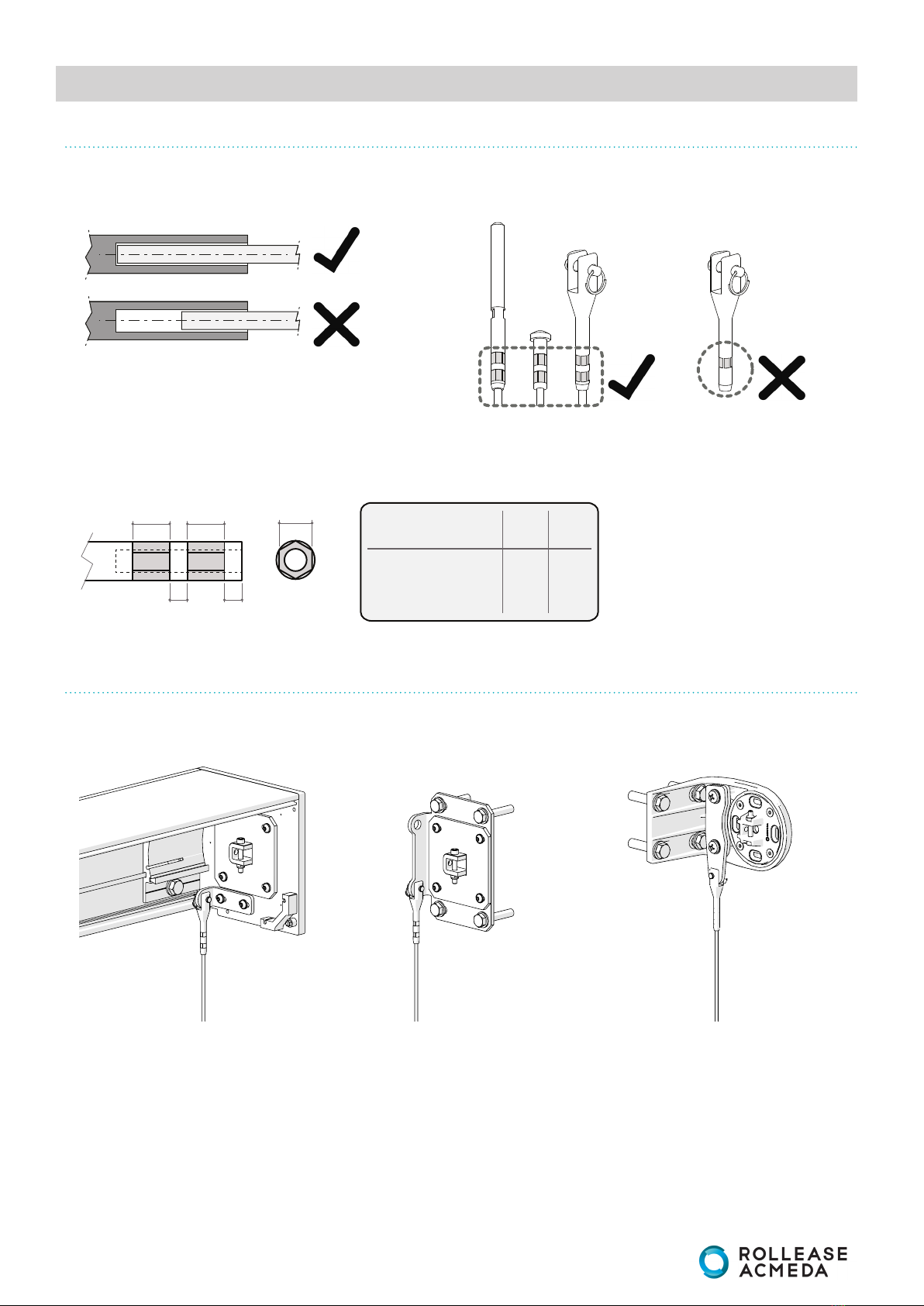

MINIMUM CRIMP SPECIFICATIONS

STEP 4 ATTACH FORK TERMINAL (CRIMPED) TO WIRE GUIDE ADAPTOR

a) Ensure cable is fully inserted into terminal b) Ensure 2x crimps minimum per terminal.

NOTE: Ensure jaws of crimp tool close completely to achieve maximum possible crimp strength - use dimension A as a guide.

c) Crimp guide - refer to tools section for recommended crimp tool.

Refer to table below for guide of crimp position and sizing for all terminals.

MOUNTING WIRE GUIDE TERMINALS