10

Rescue plan

WARNING: Asuitableandsufcientriskassessmentmustbecarriedout

beforecommencingwithanykindofworkatheight,oranyworkthatrequires

theuseofpersonalprotectiveequipment(PPE)asacontrolmeasure.

• The user must have a rescue plan and the means at hand to implement it

• Theplanmusttakeintoaccounttheequipmentandspecialtrainingnecessary

toeffectivelyconductpromptrescueunderallforeseeableconditions

Accessories

• Additionalfallarrestgear,workwearandotherpersonalprotectionequipment

isavailablefromyourSilverlinestockist

Maintenance

Note: Allfallarrestequipmentmustberegularlyinspected,cleanedand

maintainedbyacompetentperson,inaccordancewithlocallawsand

regulations. Maintenance must be recorded in a dedicated service record (see

endofthismanual).

WARNING: Carryoutavisualandtactileinspectionofallcomponentsevery

timetheequipmentisused.Carryoutadetailedexaminationiftheequipment

has not been used for some time.

Note: Athorough,detailedexaminationoftheequipmentmustbecarriedoutat

regularintervals,atleastonceannually,ormorefrequentlydependingonuse.

WARNING: ItisILLEGALtocarryoutanykindofrepairormodicationto

this equipment.

WARNING: Shouldanydamagebedetected,removetheequipmentfrom

serviceimmediately.Itmustthenberenderedunusableanddiscarded.

Harness visual/tactile inspection

Thefollowingdefectspotentiallyresultindegradationand/orweakeningof

equipment components:

• Cutsof1mmormoreattheedgesofwebbing

• Surfaceabrasionacrossthefaceofthewebbing,atwebbingloopsandaround

the edges

• Damage to stitching

• Knotsotherthanthoseintendedbythemanufacturer

• Chemicalattackpotentiallyresultinginlocalweakeningandsoftening(often

indicatedbyakingofthesurface).Discolourationofthebresmayalsobe

present

• Heatorfrictiondamageindicatedbybreswithaglazedappearancewhich

mayfeelharderthansurroundingbres

• UV-lightdegradationwhichcanbedifculttoidentify,particularlyvisually,but

theremaybesomelossofcolour(ifdyed)andapowderysurface

• Partiallydeployedenergyabsorber(e.g.shortpull-outoftearwebbing)

• Contamination(e.g.withdirt,grit,sandetc.)whichmayresultininternalor

external abrasion

• Damaged,oxidisedordeformedttings(e.g.karabiners,screwlink

connectors,scaffoldhooks)

• Damage to the sheath and internal damage to the core of a rope

Note: See ‘Service life and product obsolescence’ if such damage or other

defects are detected during inspection.

Karabiner & lanyard inspection procedure

• Thefollowingprocedurehelpsdetectdefectspotentiallyresultingin

degradationand/orweakeningoftheKarabiner(13)andScaffoldHook(9):

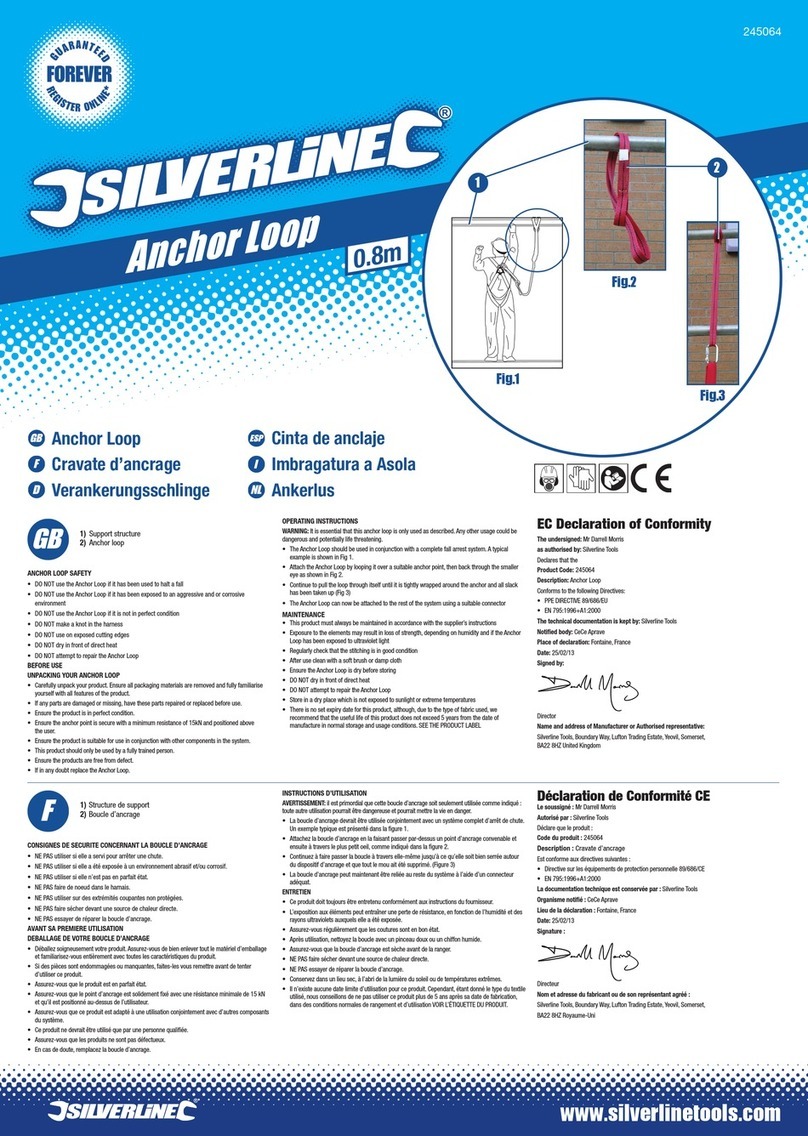

1. Inspectformissingoralteredparts.Refertotheimagein‘Product

Familiarisation’foridentication.Verifyeachitemispresentandhasnotbeen

tamperedwith

2. InspecttheentireKarabinerorhookforcracks,nicksorbreaksinthemetal.

Inspecteverymillimetre

Note:Ifnecessary,cleanbeforeinspection,tobeabletodetectevensmall

hairlinecracks.

3. Inspectfordeformation,bentordentedparts.OpentheGate(17)andinspect

theNose(14)oftheKarabinerorhookforsignsofwear,distortionordamage

4. Inspectthemetalsurfaceforanysignsofcorrosion.Steelkarabinersand

hooksmayshowreddustasevidenceofcorrosion,aluminiumkarabinersmay

develop pitting or scales

5. Inspectforheatdamage,whichcanusuallybeseenasdiscolorationor

darkeningofthemetalsurfaces

6. Performafunctionaltest:Thelockingmechanismmustfunctioneasily,and

theKarabinerorHookmustfullyopenandclosesmoothlyandeasily.When

locked,theGateMUSTNOTopenunderpressurefromanydirection

• Slowlypasstheropethroughyourhandstodetectsmalldefects,abrasions

andtwistdamage.Feelforsofteningandhardeningofbresandlookfor

ingress of contaminants

• Thefollowingdefectspotentiallyresultindegradationand/orweakeningof

thelanyard:

• Cut/brokenbresornicks

• Kinks,knots(otherthanthoseintendedbythemanufacturer)orhockling

(unravellingduetoconstantturningoftheropeinthesamedirection,or

duetoshockloading)

• Brittle,fuzzyorwornbres,frayingorabrasions

• Overall deterioration or discolouration

• Anykindofmodication/attemptedrepairs

• Hardorshinyspots,fusedbresorstrands

• Heatorfrictiondamageindicatedbybreswithaglazedappearance

whichmayfeelharderthansurroundingbres

• Burnt,charredormeltedbresorstrands

• Changeindiameter,comparedtotheoriginaldiameter(see

‘Specication’)

• Ropemarkedwithpaintorapermanentmarker

• Loose,missing,deformedordamagedRopeThimble(12)

• Eyedamage(cuts,nicks,fraying,fusing,abrasionetc.)

• Damage to protective covers/sleeves/sheaths

• Splicesstartingtounravel,orshowingsignsofdamageordeterioration

• Partiallydeployedenergyabsorber(e.g.shortpull-outoftearwebbing)

• Damage to stitching

• Chemicalattackpotentiallyresultinginlocalweakeningandsoftening

(oftenindicatedbyakingofthesurface)

• UV-degradationwhichisdifculttoidentify,particularlyvisually,butthere

maybesomelossofcolour(ifdyed)andapowderysurface

• Contamination(e.g.withdirt,grit,sandetc.)whichmayresultininternal

or external abrasion

• Damaged,oxidisedordeformedttings(e.g.karabiners,screwlink

connectors,scaffoldhooks)

• Inspectallothercomponentsorsubsystemofthefallarrestequipment

accordingtomanufacturer'sinstructions

• Record inspection date and results in a dedicated service record (see end of

thismanual)

Note: Referto‘Servicelifeandproductobsolescence’ifanydamageorother

defects are detected during inspection.

Cleaning

Note: Correctcleaningisessentialtoensureintegrityofthisequipment.Follow

thecleaninginstructionsbelowwithoutdeviation.

• Cleanlanyard,webbingstrapsandbucklesinwarmwater(30–60°C)with

amildpHneutral(pH7)householddetergent.Intheeventofminorsoiling,

wipewithacottonclothorcarefullycleanusingasoftbrush

Note: Takecarethatwaterdoesnotenterunderneaththeprotectivesheathof

theEnergyAbsorber(10).Incaseofminorsoiling,wipewithacottonclothor

carefullycleanusingasoftbrush.

• CleantheKarabiner(13)andhookbywipingitwithasoft,lightlyoiledcloth

• DONOTunderanycircumstancesuseanyabrasivematerials,acids,basic

detergents or solvents

• Disinfectpartsthatcomeintocontactwiththeoperator’sskin,usinga

disinfectantsuitableforthematerialoftheequipment(see‘Specication’).

Strictlyfollowthedisinfectantmanufacturer’srecommendationsand

procedures

255234_Manual.indd 10 13/12/2019 09:30