8. Fill fuel tank with gasoline before starting the en-

gine. Avoid spilling gasoline. Since gasoline is flam-

mable, handle it carefully.

A. Use an approved gasoline container.

B. Do not fill tank while engine is hot or

running.

C. Do not smoke while handling gasoline.

While Operating

10. DON’T TAKE AN INJURY RISK! When a person or

pet appears unexpectedly in or near the WORKING

area, STOP AERATING.

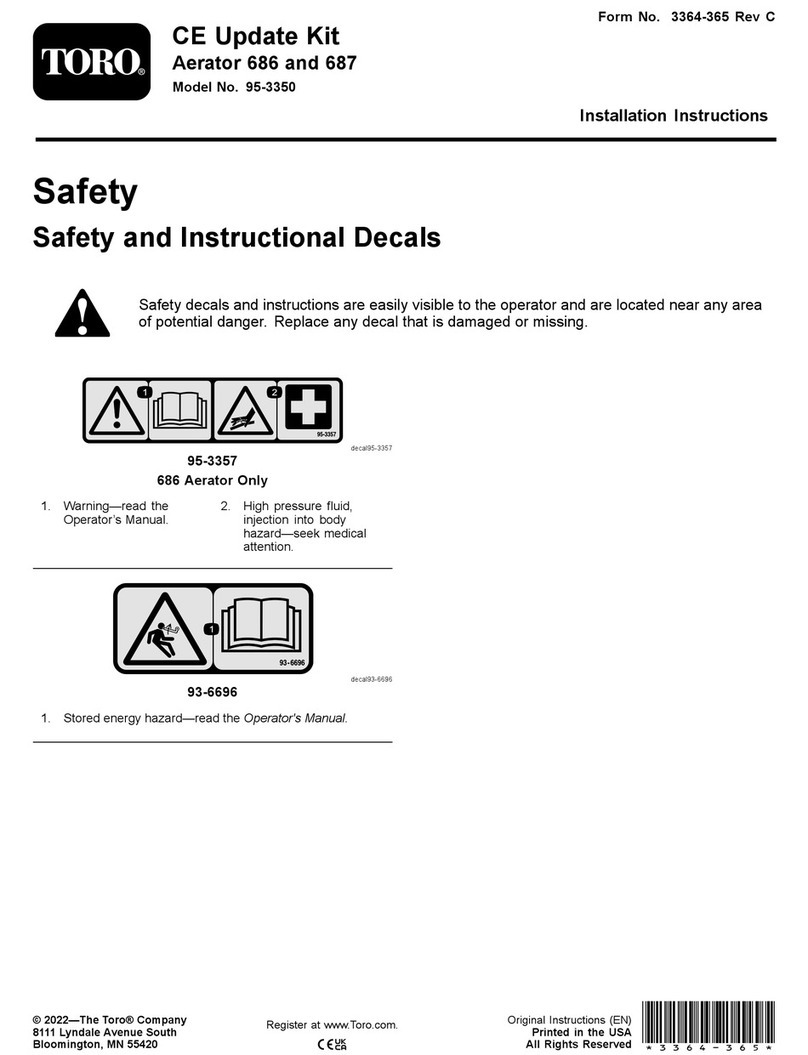

11. Keep hands and feet away from nozzle and roller

area. High velocity water jets can penetrate hands and

feet. Penetration by the high velocity water jets can

cause serious personal injury. If accidental penetration

occurs, seek medical attention immediately.

12. Never use chemicals in the water supply system.

13. Do not operate water injection system on concrete

or asphalt because water jets will permanently damage

these surfaces.

14. Start engine with parking brake engaged.

15. Do not run the engine in a confined area without ad-

equate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

16. Using the machine demands attention, and to pre-

vent loss of control:

Maintenance

21. Disconnect wires from spark plugs to prevent acci-

dental starting of the engine when servicing, adjusting or

storing the machine.

22. If machine must be tipped to perform maintenance

or an adjustment, close fuel shut–off valve, drain gaso-

line from fuel tank, oil from crankcase and remove bat-

tery.

23. To reduce potential fire hazard, keep the engine free

of excessive grease, grass, leaves and accumulations

of dirt.

24. Be sure machine is in safe operating condition by

keeping nuts, bolts and screws tight. Check all bolts and

nuts frequently to be sure they are tightened to specifi-

cation.

25. If the engine must be running to perform a mainte-

nance adjustment, keep hands, feet, clothing and other

parts of the body away from any moving parts.

26. Make sure all hydraulic line connectors are tight, and

all hydraulic hoses and lines are in good condition be-

fore applying pressure to the system.

Safety Hydroject 3010

D. Fill fuel tank outdoors and up to about one

inch (25 mm) from top of the tank, not the

filler neck.

E. Wipe up any spilled gasoline.

9. Check interlock switches daily for proper operation.

If a switch fails, replace it before operating the machine.

The interlock system is for your protection, so do not by-

pass it. Replace all interlock switches every two years.

A. Use only in daylight or when there is good

artificial light.

B. Watch for holes or other hidden hazards.

C. Do not transport machine close to a sand

trap, ditch, creek or other hazard.

17. If the machine starts to vibrate abnormally, shut the

engine off. Remove wires from spark plugs to prevent

possibility of accidental starting. Check machine for

damage and defective parts. Repair any damage before

restarting the engine and operating the machine.

18. Do not touch engine or muffler while engine is run-

ning or soon after it is stopped. These areas could be hot

enough to cause a burn.

19. Before leaving the operator’s position–behind han-

dle–engage parking brake.

20. When leaving the machine unattended, engage

parking brake , shut engine OFF and remove key from

ignition switch.

27. Keep body and hands away from pin hole leaks or

nozzles that eject water or hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to search

for leaks. Hydraulic fluid or water escaping under pres-

sure can have sufficient force to penetrate skin and do

serious damage. If either of these fluids are ejected into

the skin they must be surgically removed within a few

hours by a doctor familiar with this form of injury or gan-

grene may result.

28. Before disconnecting or performing any work on the

hydraulic oil system, all pressure in system must be re-

lieved by stopping engine and opening by–pass valve.

29. Make sure all water line connectors are tight, and all

hoses and lines are in good condition before applying

pressure to the system.

Page 1 – 2