ENGLISH

- 10 -

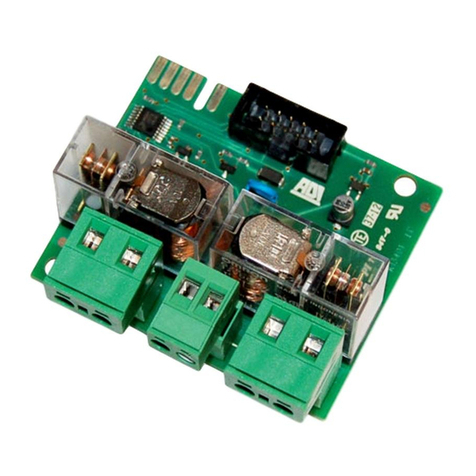

DESCRIPTION OF THE CONTROL UNIT

TheFLEXY2controlunitisaninnovativeV2productguaranteeing

safetyandreliabilityforswinggateautomation.

TheFLEXY2designhasbeenaimedatcreatingaproductwhich

adaptstosuitallneeds,thusobtaininganextremelyversatile

controlunitsatisfyingallthenecessaryrequirementsfora

functionalandefcientinstallation.

• 230V-50Hzor120V-60Hzpowersupplies,dependingonthe

model,for2singlephasemotors(700Wglobal).

• Inputforkeyswitchorpush-button.

• Inputforsafetyphotocell.

• Inputforsafetyedge,capableofhandlingstandardedges

withswitchnormallyclosedandconductiverubberedgeswith

nominalresistanceof8.2kOhms.

• Inputsforopenandcloselimitswitches

• Pre-openingsafetydevicetesting.

• Dip-switchprogrammableoperationallogic.

• Adjustmentofmotorpowerandoperationtimebymeansofa

trimmer.

• Fitted433.92MHzradioreceiver

• Possibilityofsaving240PersonalPasstransmitters

(433.92MHz)

• LEDmonitoringofinputs.

• Courtesylightoutput.

• RJ45connectortoconnectthecontrolunittotheprogrammer

PROG2viastandardnetworkcable(UTP)

• IP55casing.

INSTALLATION

Installationofthecontrolunit,thesafetydevicesandaccessories

mustbeperformedwiththepowersupplydisconnected.

POWER SUPPLY

Thecontrolunitmustbepoweredbymeansofa230V-50Hz

or120V-60Hzpowerline,dependingonthemodel,protected

byadifferentialmagnetothermalswitchincompliancewithlegal

regulations.

ConnectthepowercablestothecontrolunitLand Nterminals.

MOTORS

ThecontrolunitcancontroloneortwoasynchronousACmotors.

Ifthecontrolunitisusedtocontrolonlyonemotor,thenthis

mustbeconnectedtotheterminalsrelatingtomotor1.

Connectthecablesformotor1asfollows:

• OpeningcabletoterminalK3

• ClosingcabletoterminalK5

• CommonreturncabletoterminalK4

• Start-upcapacitorbetweenterminalsK3 and K5

Connectthecablesformotor2(ifpresent)asfollows:

• OpeningcabletoterminalK6

• ClosingcabletoterminalK8

• CommonreturncabletoterminalK7

• Start-upcapacitorbetweenterminalsK6 and K8

PHOTOCELLS

Thecontrolunithasa24VACpowersupplyforphotocellswith

switchnormallyclosed,andcanperformanoperationaltest

beforetostartingthegateopeningprocedure.

Thephotocellcanbeusedwithtwosettings:

1. Photocell always active:

Interventionofthephotocellduringopeningorclosingcauses

thegatetostop.Whenthephotocellrestores,thegatere-

opens completely.

2. Photocell NOT active during opening:

Interventionofthephotocellduringopeningisignored.

Interventionofthephotocellduringclosingcausesthegateto

re-open completely.

Independentlyofthesettingselected,whenthegateispaused

whileopening,thetimecountforanyautomaticre-closurewill

onlystartafterthephotocellrestores.

• Connectthephotocelltransmitterpowercablesbetween

terminals L10 (GND)andL11 (+)onthecontrolunit.

• Connectthephotocellreceiverpowercablesbetweenterminals

L10 (GND)andL9 (+)onthecontrolunit.

• ConnectthephotocellreceiveroutputbetweenterminalsL4

and L8 on the control unit.

SAFETY EDGES

Thecontrolunithasaninputforcontrollingsafetyedges;this

inputiscapableofcontrollingstandardedgeswithswitch

normallyclosedandconductiverubberedgeswithnominal

resistanceof8.2kOhms.

Edgescanbeusedwithtwosettings:

1. Edge always active:

Interventionoftheedgeduringopeningorclosingcauses

inversionofthedirectionofmovementinordertofreethe

bodythatcausedtheedgetointervene.Thegatestopsafter

approx. 3 seconds.

2. Edge NOT active during opening:

Interventionoftheedgeduringopeningisignored.

Interventionoftheedgeduringclosingcausesthegateto

re-open completely.

Independentlyofthesettingsselected,anysubsequentautomatic

re-closurewillbecancelled.

Standard edge with switch normally closed: connecttheedge

cablesbetweenterminalsL5 and L8 on the control unit.

InordertosatisfytherequirementsofstandardEN12978,it

isnecessarytoinstallsafetyedgeswithacontrolunitwhich

constantlymonitorscorrectoperation.Ifcontrolunitsareused

withtheoptionofrunningtestsbymeansofinterruptingthe

powersupply,connectthecontrolunitpowersupplycables

betweenterminalsL10(GND)andL11(+).

Conductive rubber edge:connecttheedgecablesbetween

terminalsL5andL8onthecontrolunit.

mPLEASE NOTE: operational testing on edges is

reserved for standard edges (only if equipped with suitable

control units).

DO NOT enable testing if conductive rubber edges are used

or standard edges used without a suitable control unit for

controlling function.