ENGL SH

28

MPORTANT REMARKS

For any installation problem please contact our Customer Service

at the number +39-0172.812411 operating Monday to Friday

from 8:30 to 12:30 and from 14:00 to 18:00.

V2 has the right to modify the product without previous

notice; it also declines any responsibility to damage or

injury to people or things caused by improper use or

wrong installation.

Please read this instruction manual very carefully

before installing and programming your control unit.

• This instruction manual is only for qualified technicians,

who specialize in installations and automations.

• The contents of this instruction manual do not concern the

end user.

• Every programming and/or every maintenance service

should be done only by qualified technicians.

AUTOMAT ON MUST BE MPLEMENTED N COMPL ANCE

W TH THE EUROPEAN REGULAT ONS N FORCE:

EN 60204-1 (Machinery safety. electrical equipment of

machines, part 1: general rules)

EN 12445 (Safe use of automated locking devices,

test methods)

EN 12453 (Safe use of automated locking devices,

requirements)

• The installer must provide for a device (es. magnetotermical

switch) ensuring the omnipolar sectioning of the equipment

from the power supply.

The standards require a separation of the contacts

of at least 3 mm in each pole (EN 60335-1).

• After making connections on the terminal board, use one

hose clamp to fix dangerous voltage wires near the terminal

board and another hose clamp to fix safety low voltage wires

used for accessories connection; this way, in case of

accidental detachment of a conducting wire, dangerous

voltage parts will not come into contact with safety low

voltage ones.

• The plastic case has an IP55 insulation; to connect flexible

or rigid pipes, use pipefittings having the same insulation

level.

• Installation requires mechanical and electrical skills,

therefore it shall be carried out by qualified personnel only,

who can issue the Compliance Certificate concerning the

whole installation (EEC Machine Directive 89/392, Annex IIA).

• The automated vehicular gates shall comply with the

following rules: EN 12453, EN 12445, EN 12978 as well

as any local rule in force.

• Also the automation upstream electric system shall comply

with the laws and rules in force and be carried out

workmanlike.

• The door thrust force adjustment shall be measured

by means of a proper tool and adjusted according to

the max. limits, which EN 12453 allows.

• We recommend to make use of an emergency

button, to be installed by the automation (connected

to the control unit STOP input) so that the gate may

be immediately stopped in case of danger.

• Always remember to connect the earth according to

current standards (EN 60335-1, EN 60204-1).

DECLARAT ON OF CONFORM TY

V2 S.p.A. hereby declare that CITY2+ products conform to the

essential requirements established in the following directives:

- 89/336/CEE (EMC Directive in accordance with standards

EN 55014-1, EN 55014-2, EN 61000-3-2, 61000-3-3)

- 2006/95/CEE (Low Voltage Directive in accordance with

standards EN 60335-1 + EN 60335-2-103)

- 99/05/CEE (Radio Directive in accordance with standard

EN 301 489-3)

Racconigi, 12/01/2009

V2 S.p.A. legal representative.

Antonio Cristina

TECHN CAL SPEC F CAT ONS

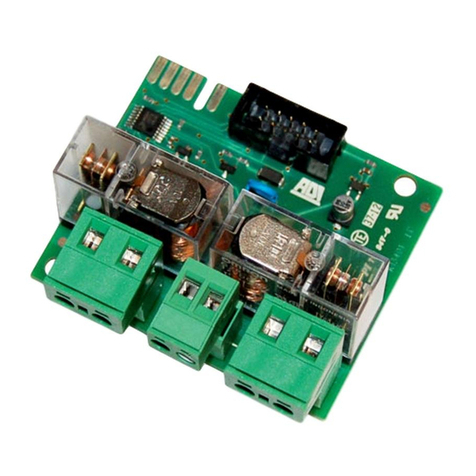

DESCR PT ON OF THE CONTROL UN T

The digital control unit C TY2+ is an innovative V2 product that

guarantees a safe and reliable automation of leaf swing or

sliding gates.

C TY2+ is provided with a display that, not only makes

programming simple, but also allows a continuous monitoring of

the input statuses; in addition, thanks to a menu structure, the

working schedule and the operation logic can be set easily.

In compliance with the European standards concerning

electrical safety and electromagnetic compatibility

(EN 60335-1, EN 50081-1 and EN 50082-1) it has been

equipped with the low voltage circuit total electric insulation

(motors included) from the network voltage.

Other characteristics:

• Power supply protected from short circuits within the

controller, on the motors and on the connected accessories.

• Adjustment of the power by partializing the current.

• Detecting obstacles by monitoring the current on the motors

(current sensing probe)

• Automatic learning of the operation time.

• Tests for safety devices (photocells, safety ribbons and

mosfet) before each opening.

• Deactivation of safety inputs through the configuration

menu: no jumper is required for terminals concerning safety

devices that have not been installed, yet. You will only need

to disable this function from its relevant menu.

• The device can operate without mains power, by using the

optional battery pack (code 161212).

• Low voltage output that can be used for a signal light or a

24 V flashing light.

• Auxiliary relay with programmable logic for courtesy light,

flashing light or other use.

C TY2+

Power supply 230VAC - 50Hz

Max total load 250W

Max load for each motor 150W

Duty clcle 40%

Max accessories load 24Vdc 15W

Working temperature -20 ÷ +60°C

Protection fuse F1 = 2,5A

Dimensions 295 x 230 x 100 mm

Weight 3000g

Protection IP55