plik: Instrukcja RTD-01 v1.3 en | modykacja: 20.11.2014

PROGRAMME SETTINGS – CONTINUATION

ERROR MASSAGES

CAUTION

HEATING INSTALLATION SETTING

Menu → Setting→ Install.

A/ Heating setting: adjust oor type (choose from the attached list), Adaptive (switching on the function causes the system

heats before returning home, PI controller (switching it on causes the heating system accurately reaches the target

temperature), First warning. It is a rst heating function. It must be activated during the rst time the room oor is heated.

The thermostat has this functionality for 21 days and then it will automatically switch off drying of the oor. This function can

be switched off at any time.

B/ Set offset:

Its aim is to calibrate the regulator’s temperature. For the room and oor sensors the adjustment is possible within -8 to

+8°C range.

C/ Program period set: The 24 hour day can be divided into 4 or 6 adjustment periods.

Default setting of the day is 6 periods.

D/ Set sensor (oor sensor adjustment). It is necessary to choose the sensor used in the oor. The regulator enables the

application not only of a oor sensor included in the set with a regulator (SASWELL100k) but also a sensor by other

producers. The regulator cooperates and the following sensors can be chosen: SASWELL 100k, SASWELL 10k, DEVI 15k,

OJ12k, Eberle 33k, Ensto 47k, FENIX 10k, TYCO 10k, Teplolux 6K8, Warmup 12k, aube 10k.

E/ Reset. It causes the return to default settings. YES conrmation causes the return to the default settings.

In case the expected temperature is higher than the real one, an icon meaning heating will appear on the screen:

TIME SETTING

Menu → Time (Date setting) → Next (Hour setting).

Adjust date by means of arrows up / down (day/mounth/year or year/mounth/day). By means of Next (Dalej) function we pass

to hour adjustment (hour/minute/second). The Next function helps to choose day format, mode, 12 hour or 24 hour format.

Conrm by Apply.

In case of power supply failure the clock resets and it is necessary to adjust date and time again.

The following massages can be displayed:

- „ The oor temperature sensor short-circuit. Please check it.” It is necessary to check if the oor sensor cable insulation

is damaged or the sensor wires are short circuited.

- „The oor tempereture sensor open circuit. Please check it.” It is necessary to check the wire connection of the external

sensor to the regulator. Check if the external sensor’s wire are not broken.

- „The room stemperature sensor short-circuit. Please check.”- It is necessary to check if the sensor protruding from the

bottom of the casing is damaged.

- „The room temperature sensor open circuit. Please check it.”- It is necessary to check if the sensor protruding from the

bottom of the casing is damaged.

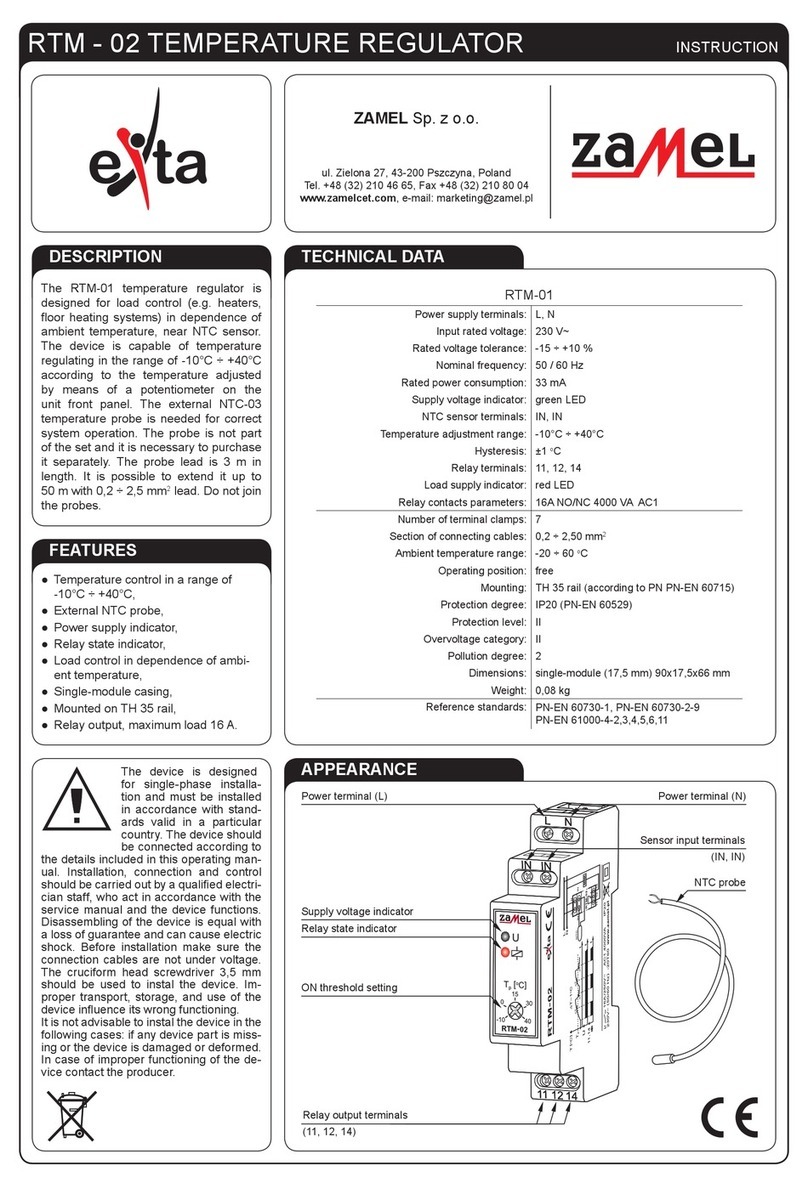

The device is designed for single-phase installation and must be installed in accordance with standards valid in a particular country. The

device should be connected according to the details included in this operating manual. Installation, connection and control should be carried

out by a qualied electrician staff, who act in accordance with the service manual and the device functions.

In case of casing dismantling an electric shock may occur, and the guarantee is lost then. Before installation make sure the connection cables

are not under voltage. The cruciform head screwdriver 3,5 mm should be used to mount the device. Improper transport, storage, and use of the

device inuence its wrong functioning. It is not advisable to mount the device in the following cases: if any device part is missing or the device

is damaged or deformed. In case of improper functioning of the device contact the producer.

page: 6

WARRANTY CARD

There is 24 months guarantee on the product

Salesman stamp and signature, date of sale

1. ZAMEL Sp. z o.o. assures 24 months guarantee for the product.

2. The manufacturer’s guarantee does not cover any of the following actions:

a) mechanical damage during transport, loading / unloading or under other circumstances,

b) damage caused by incorrect product mounting or misuse,

c) damage caused by unauthorised modications made by the PURCHASER or any third parties to the product

or any other devices needed for the product functioning,

d) damage caused by Act of God or any other incidents independent of the manufacturer - ZAMEL Sp z o.o.

e) supply sources (batteries) included in the device during selling (if they are included).

3. The PURCHASER shall lay any claims in writing to the dealer or ZAMEL Sp. z o.o.

4. ZAMEL Sp. z o.o. is liable for processing any claim according to current Polish legislation.

5. ZAMEL Sp. z o.o. shall process the claim at its own discretion: product repair, replacement ormoney return.

6. The manufacturer’s guarantee is valid in the Republic of Poland.

7. The PURCHASER’s statutory rights in any applicable legislation whether against the retailer arising from the

purchase contract or otherwise are not affected by this warranty.

ZAMEL Sp. z o.o.

ul. Zielona 27, 43-200 Pszczyna, Poland

Tel. +48 (32) 210 46 65, Fax +48 (32) 210 80 04

plik: Instrukcja RTD-01 v1.3 en | modykacja: 20.11.2014

DESCRIPTION

TECHNICAL PARAMETERS

FEATURES

The temperature regulator RTD-01

is a 7-day programmable regulator

designed for electric oor heating

systems. It is operated by means of

a touch screen.

The regulator is mounted on a wall

in a junction box ¢60 x 60 mm. It is

compatible with oor sensors: SAS-

WELL 100k, SASWELL 10k, DEVI

15k, OJ12k, Eberle 33k, Ensto 47k,

FENIX 10k, TYCO 10k Teplolux 6k,

Warmup 12k, Aube 10k.

Supply terminals: N (1), L (2)

Power supply voltage: 100÷240 V AC

Nominal frequency: 50/60 Hz

Nominal power consumption: 1,5 W (STANDBY)

Battery backup: no

NTC sensor terminal: (6), (7)

Temperature sensor: NTC 10k lub 100k dla 25°C

Room temperature range: +5 ÷ +35°C

Floor temperature range: +5 ÷ +40°C

Operating temperature range: 0 ÷ +50°C

Temperature range during transport : -10 ÷ +60°C

Temperature measuring accuracy: ±0,5°C

Output terminals: (3), (4)

Type of output: voltage contact 1NO-16 A / 250 V AC

Number of connecting cables: 7

Cross section of connecting cables: 0,5 ÷ 2,5 mm2

Humidity: <90%, without condensation

Mounting: deeper junction box ¢ 60 mm x 60 mm

Casing material: engineering plastic, PC

Casing protection degree: IP21

Protection class: II

Overvoltage category: II

Nominal surge voltage: 2500 V

Pollution level of a regulator: 3 A level

Application environment: 2 pollution degree (domestic application

with standard air circulation)

Ball pressure temperature: 125°C

Dimensions: 81,5 x 81,5 x 21/41 mm ( height x width x depth )

Weight: 130 g

Reference standard: PN-EN 60730-1:2012

PN-EN 60730-2-9:2011

PN-EN 55014-1

PN-EN 55014-2

PN-EN 61000-3-2

PN-EN 61000-4-3

PN-EN 61000-4-11

PN-EN 61000-4-6

• 2,4” LCD display of 320x240 pxl

resolution

• Adjustment by means of a touch

screen

• Energy monitoring function

• Anti frost protection function

• Menu includes 11 languages: En-

glish, French, German, Dutch, Rus-

sian, Polish, Norwegian, Swedish,

Danish, Finnish, Romanian.

• Cooperation with NTC sensor of dif-

ferent manufacturers

• Blockades against children

• Holiday mode (holiday)

Temperature Regulator RTD-01 MANUAL INSTRUCTION

page: 1

ZAMEL Sp. z o.o.

ul. Zielona 27, 43-200 Pszczyna, Poland

tel. +48 32 449 15 00, +48 32 210 46 65, fax +48 (32) 210 80 04

plik: Instrukcja RTD-01 v1.3 | mody kacja: 05.04.2016_plik: Instrukcja RTD-01 v1.3 | mody kacja: 05.04.2016_