AD-P03 Special DB2013 09.02

1 - 1

2.0 Details about the machine..................... 1

2.1 Operational range ...................................... 1

2.2 Manufacturer ............................................. 1

2.3 Conformity declaration .............................. 1

2.4 Details when making enquiries

and ordering .............................................. 1

2.5 Type plate ................................................. 1

2.6 Technical data ........................................... 2

2.7 On receipt of the machine ......................... 2

2.8 AMAZONE WS (Suffolk)-coulter ................ 3

2.9 AMAZONE-sabre coulter tip

(Option) ..................................................... 4

2.10 AMAZONE RoTeC-coulter ......................... 5

2.11 ydraulic circuit diagram

Pack Top seed drill AD-P Special .............. 6

2.12 Details

about noise level ....................................... 7

2.13 Declined use

of the machine .......................................... 7

3.0 Safety ...................................................... 1

3.1 Dangers when not adhering

to the safety advice ................................... 1

3.2 Qualification of operator ............................. 1

3.3 Symbols in this

instruction manual ..................................... 1

3.4 Warning pictographs and

hint symbols on the machine .................... 2

3.5 Safety conscious operation ....................... 6

3.6 Safety advice

for the operator .......................................... 6

3.7 Determination of total weight, axle loads,

load capacity of the tyres as well as the

required minimum ballast when combining

tractor and mounted implement ............... 10

4.0 Preparing for machine operation ......... 1

4.1 First fitting ................................................. 1

4.2 Setting up the machine in the field ............ 3

4.3 During operation ........................................ 3

4.4 After the first 10 hours .................................

of operation ............................................... 4

4.5 Parking the AD-P combination .................. 4

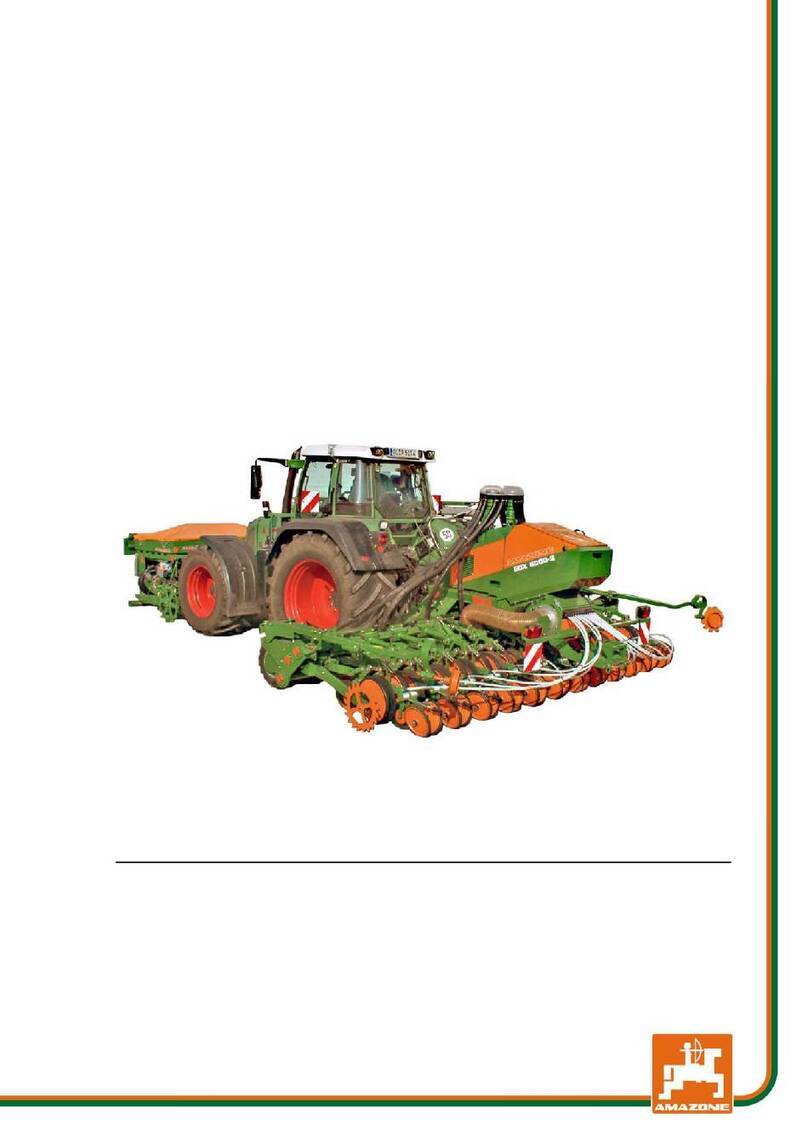

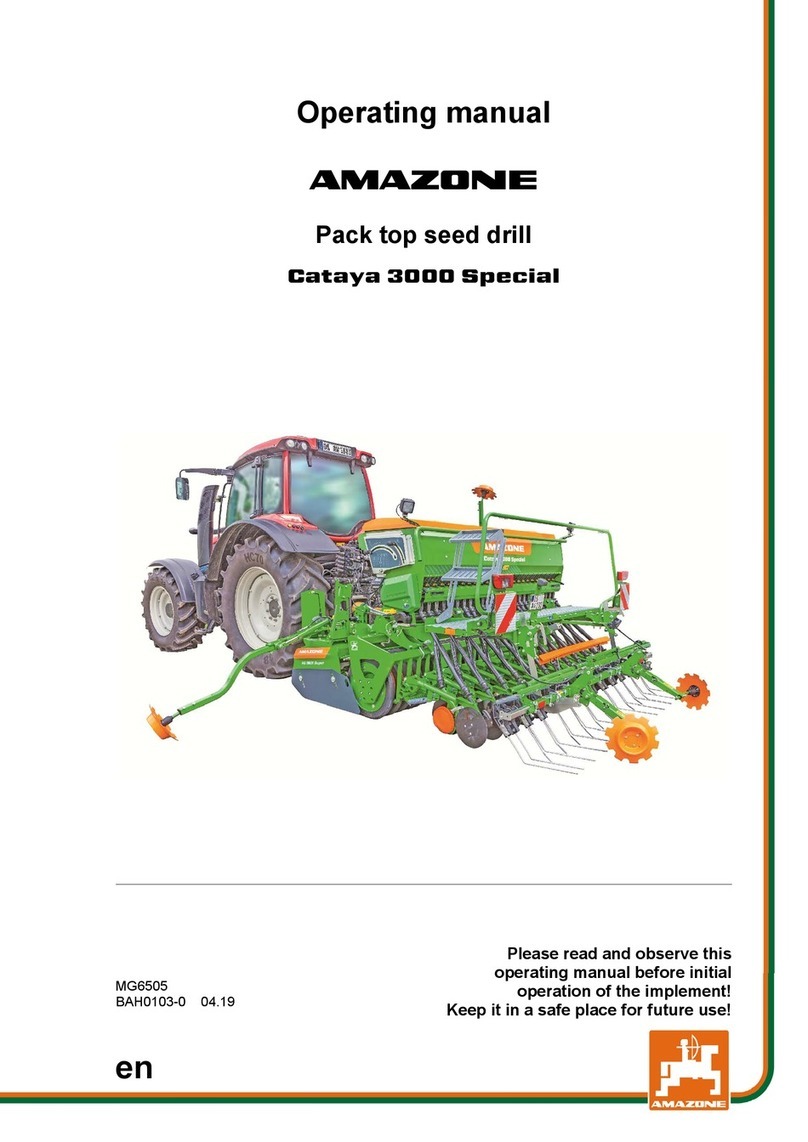

5.0 Mounting the Pack Top seed drill

AD-P Special

onto rotary harrows KE and

rotary cultivators KG .............................. 1

5.1 Equipping wedge ring rollers KW580 and

tyre packer rollers RP

with coupling parts .................................... 1

5.2 Equipping wedge ring roller KW450 and

tooth packer roller PW500

with coupling parts .................................... 2

5.3 Attaching the coupling frame

onto the rotary harrow/cultivator KE/KG .... 2

5.4 Coupling the AD-P SPECIAL ..................... 3

6.0 Attaching AMAZONE-Pack Top seed

drills AD-P Special onto soil tillage

implements of other manufacturers...... 1

6.1 Mounting the

Pack Top seed drill AD-P Special

to Kuhn rotary harrow ................................ 2

6.1.1 Basic setting of the

Pack Top seed drill

AD-P Special ............................................ 3

6.2 Mounting the

Seed drill AD-P Special

onto rotary harrows from

Messrs. Lemken/Maschio/Rabe ................ 4

7.0 Blower fan with belt drive ..................... 1

7.1 Fitting the belt drive ................................... 1

7.2 andling the

taper tensioning bushings

for V-belt pulleys ....................................... 3

7.3 Throttle flap ............................................... 4

8.0 Blower fan

with hydraulic drive ............................... 1

8.1 Blower fan speed ...................................... 1

8.2 Speed monitoring ...................................... 2

8.3 Circuit diagram

blower fan with hydraulic drive ................... 3

8.3.1 Explanations for the circuit diagram .......... 3

9.0 Seed box

filling and emptying ............................... 1

9.1 Filling the seed box ................................... 1

9.2 Emptying the seed box ............................. 2

10.0 Setting the metering unit

to a particular seed ................................ 1

10.1 Switching

the metering wheels on and off .................. 2

10.2 Sowing with both main metering wheels .... 2

10.3 Sowing

with the fine seed metering wheel .............. 3

10.4 Shear off safety ......................................... 3

11.0 Determining

the gearbox setting

for the desired seed rate ....................... 1

11.1 Calibration test .......................................... 3

11.2 Determining the gearbox setting with

the aid of the disc rule ............................... 5

11.3 Seed rate deviations between

the setting and the sowing ........................ 6

12.0 Track marker ........................................... 1

12.1 Bring markers

into operating or transport

position ..................................................... 2

12.2 Setting the marker arms

to the correct length .................................. 4

12.3 Obstacles in the field ................................ 5