2USER MANUAL

____________________________________________________________________________________________________________________

Contents:

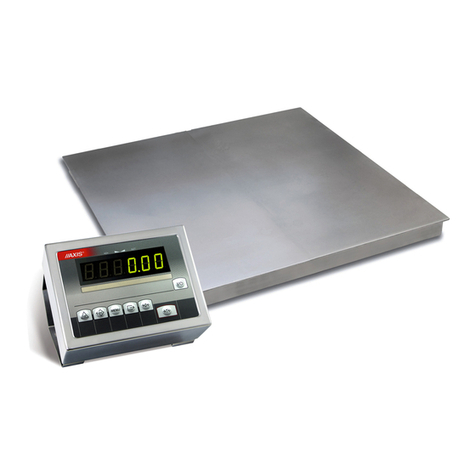

1. General description .................................................................................................................................................................. 3

2. Set .................................................................................................................................................................................... 3

3. Safety rules .............................................................................................................................................................................. 4

4. Technical data .......................................................................................................................................................................... 5

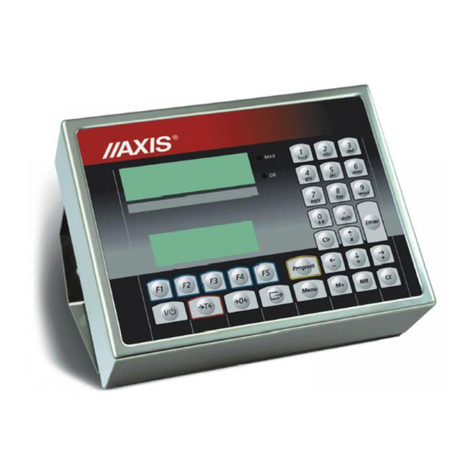

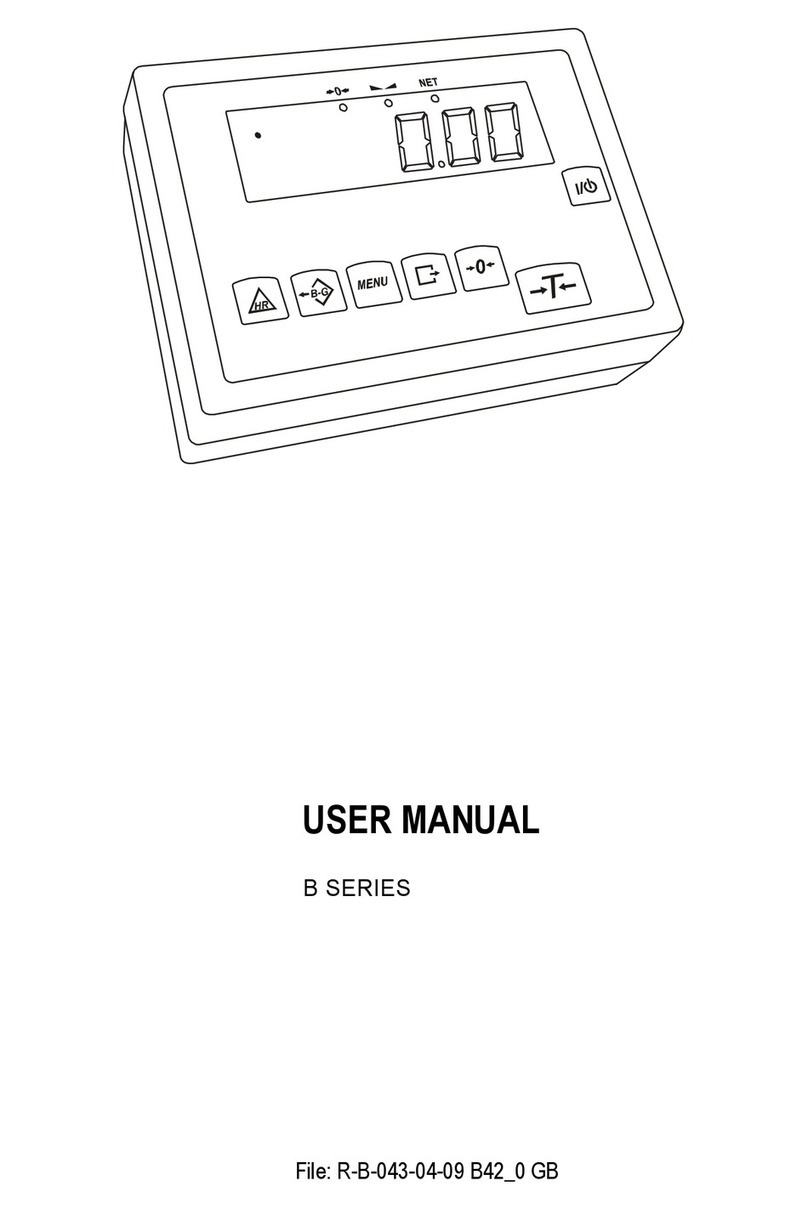

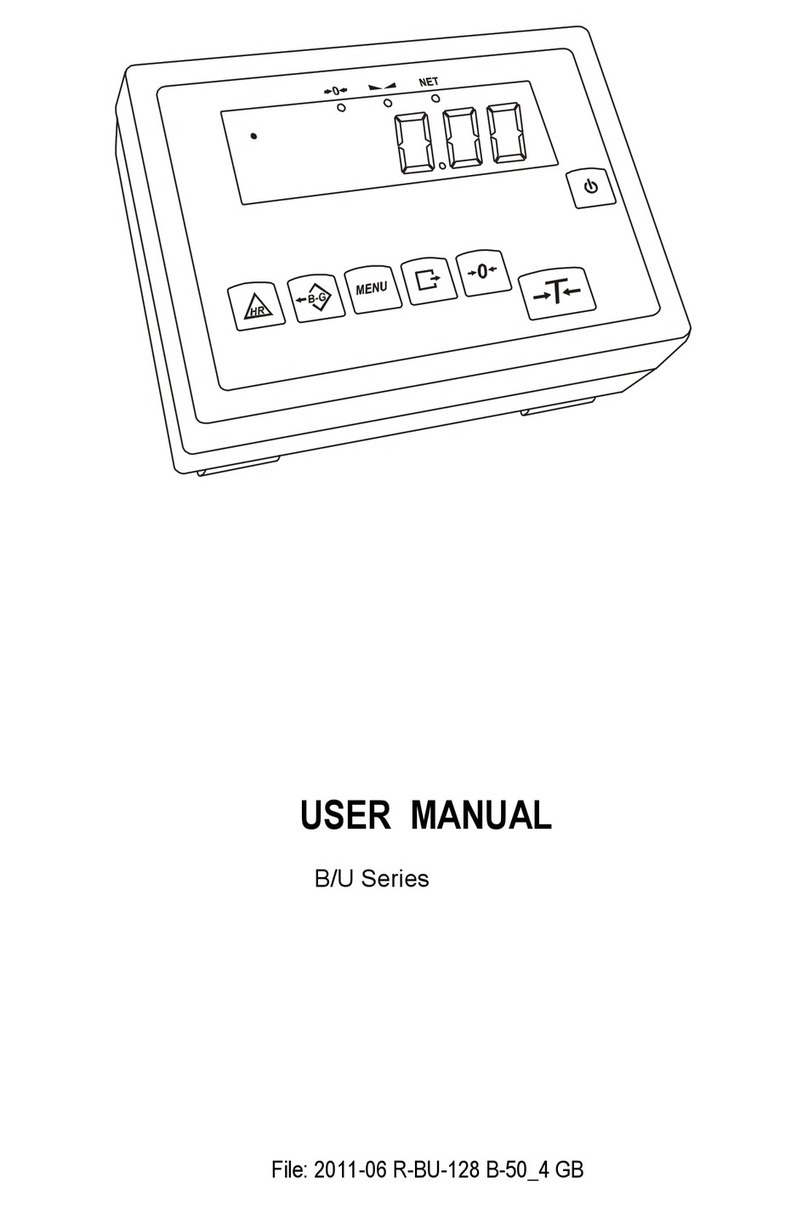

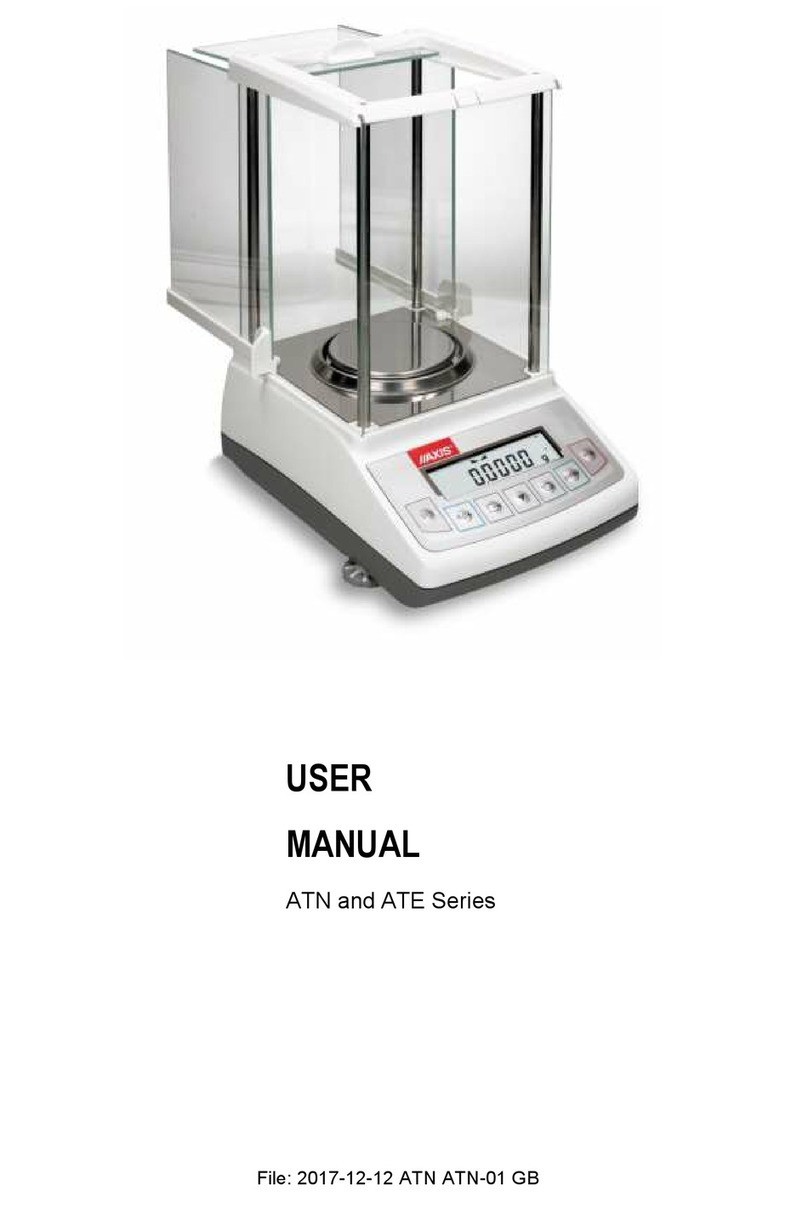

5. General balance description..................................................................................................................................................... 6

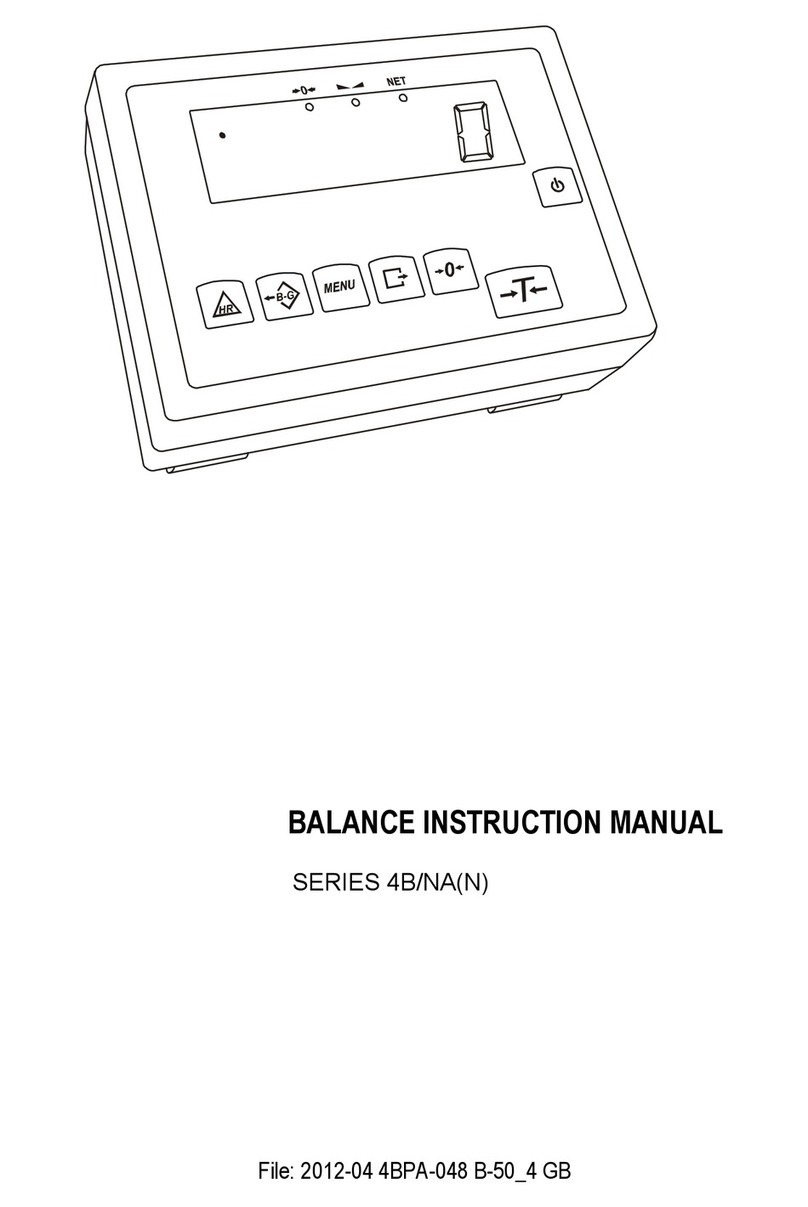

6. Keys and indicators .................................................................................................................................................................. 8

7. Preparing working environment................................................................................................................................................ 9

8. Preparing balance to work...................................................................................................................................................... 10

9. General operation principles .................................................................................................................................................. 11

10. Start-up................................................................................................................................................................................. 12

11. Internal calibration................................................................................................................................................................ 12

12. Checking the balance........................................................................................................................................................... 13

13. Connecting the balance to computer or printer .................................................................................................................... 14

14. Menu navigation ................................................................................................................................................................... 16

15. Setup .................................................................................................................................................................................. 17

15.1 Application selection –creating personalized menu................................................................................................. 18

15.2 Calibration with external weight / calibration options............................................................................................... 19

15.3 Auto-zeroing function................................................................................................................................................ 23

15.4 Unit selection ............................................................................................................................................................ 23

15.5 Interface parameters setting..................................................................................................................................... 25

15.6 Print setup................................................................................................................................................................. 26

15.7 LCD settings ............................................................................................................................................................. 28

15.8 Language selection................................................................................................................................................... 28

15.9 Setting date and time................................................................................................................................................ 29

15.10 Keyboard options...................................................................................................................................................... 29

15.11 Analog output............................................................................................................................................................ 30

15.12 Speed ....................................................................................................................................................................... 30

16. Applications .............................................................................................................................................................. 30

16.1 Product and user identification ................................................................................................................................. 32

16.2 Pieces counting ........................................................................................................................................................ 33

16.3 Unit ........................................................................................................................................................................... 34

16.4 Percentage ............................................................................................................................................................... 35

16.5 Animals weighing...................................................................................................................................................... 36

16.6 Tare setting............................................................................................................................................................... 37

16.7 Max or minimum value indication ............................................................................................................................. 38

16.8 Force indication (Newton)......................................................................................................................................... 39

16.9 Total.......................................................................................................................................................................... 40

16.10 Checkweighing function (thr) .................................................................................................................................... 41

16.11 Stats.......................................................................................................................................................................... 44

16.12 Density measurement............................................................................................................................................... 47

16.13 Recipe....................................................................................................................................................................... 51

16.14 Packing goods control (TP) ...................................................................................................................................... 52

17. Detailed information about balance communication ................................................................................................. 55

17.1 Long protocol description.......................................................................................................................................... 55

17.2 Protocol EPL description .................................................................................................................................................... 57

18. Troubleshooting and maintenance ..................................................................................................................................... 58