3

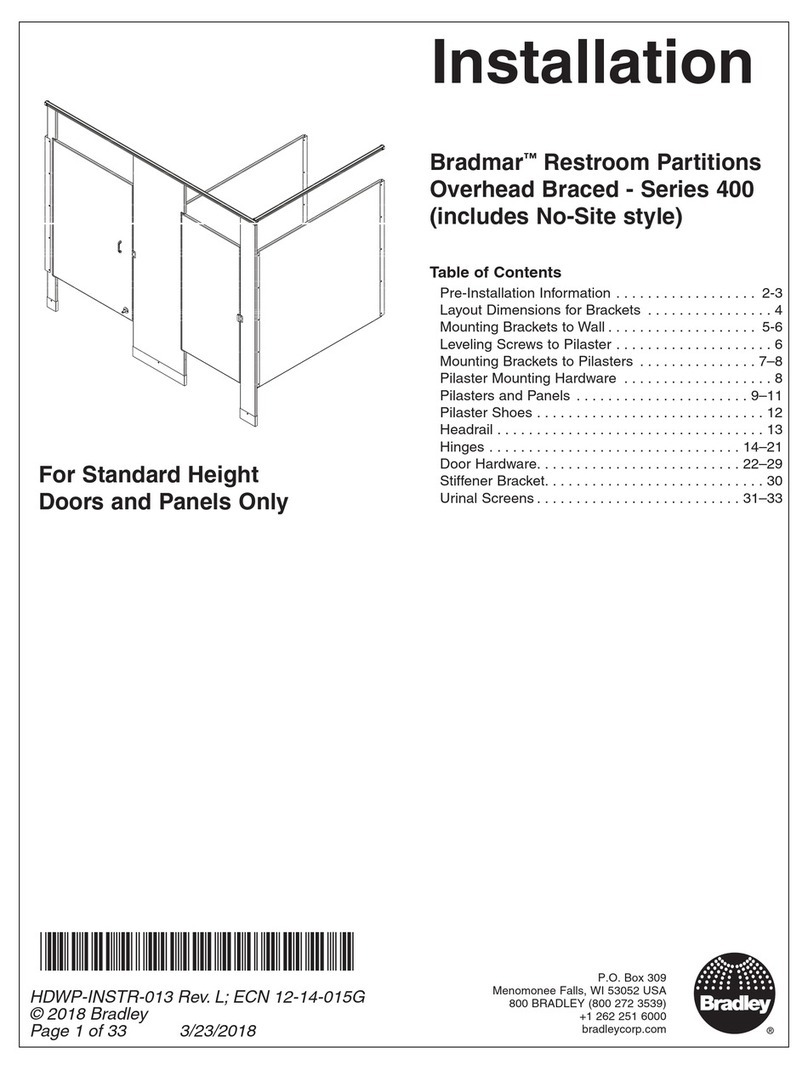

Installation Plastic Laminate Restroom Partitions, Floor-Braced — Series 500

Bradley • HDWL-INSTR-002 Rev. D; ECN 13-14-030B 8/29/2013

C

L

C

L

C

L

C

L

*

*

*

*

*

*

*

*

*

C

L

C

L

C

L

C

L

C

L

C

L

Pilaster plumb line

When installing the partition components, consult

the applicable Mills Partition submittal drawing

for compartment layout dimensions.

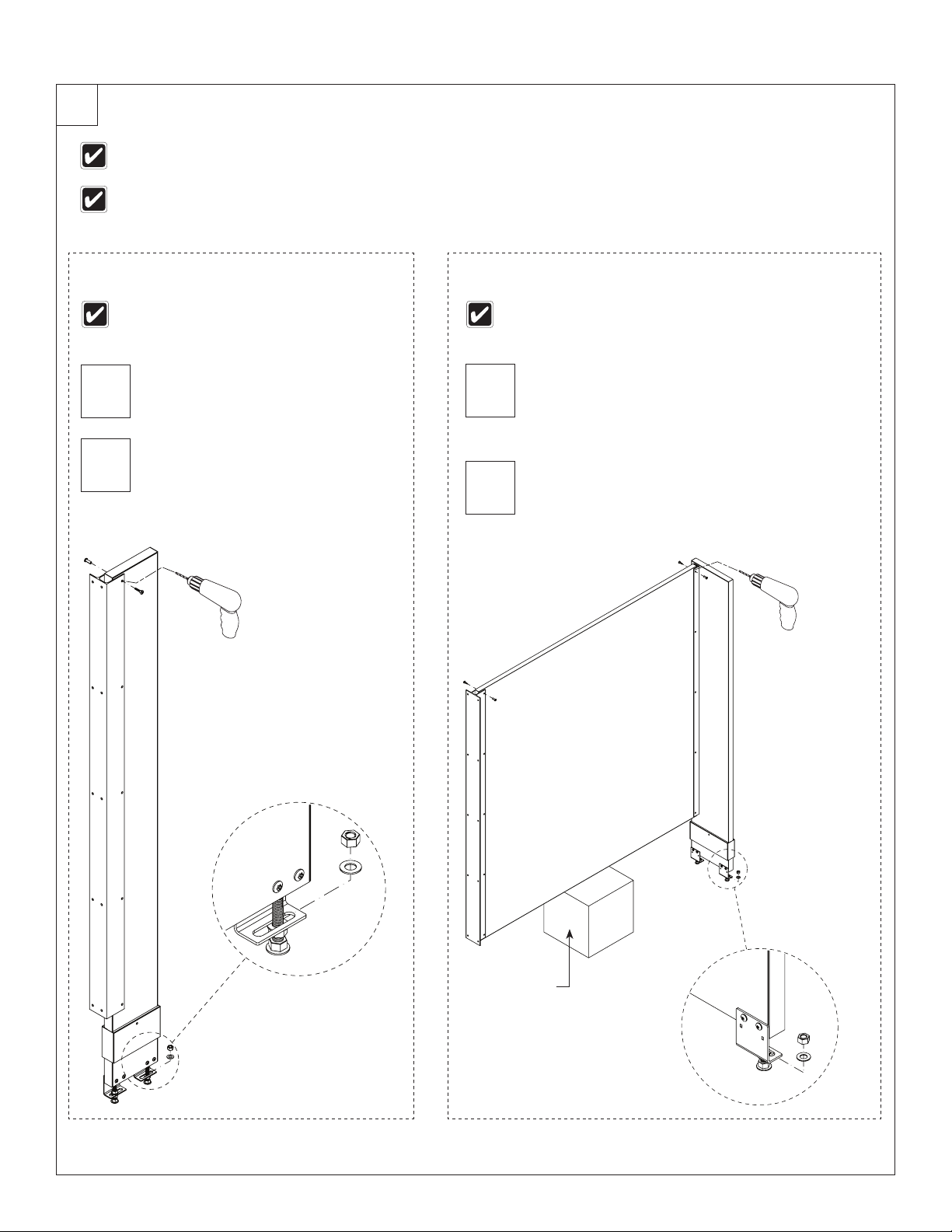

1Layout Dimensions - Stirrup Bracket (Standard)

Pilaster centerline: Measure from the back

wall forward to the face of the compartment,

subtract ⁵⁄₈" (16mm) and mark this location on

the floor (“A”). Mark the same measurement

on the opposite end of your layout (“A1”) and

draw a straight line connecting both marks.

FOR FREESTANDING (FS) PARTITIONS:

Refer to submittal drawings and determine

the approximate location of the outside

panels. Establish dimensions “A” and “A1” as

explained above.

A

Panel centerline: Measure the stall width across the

back wall and place a mark at the base of the rear wall

(“B”). Repeat this step for each panel, starting each

measurement from the last panel centerline (“B1”).

B

Stirrup brackets: Draw a plumb line on all walls

from each pilaster and panel centerline. From the

highest point in the room, measure 18" (457mm)

and 64" (1626mm) from the floor and place a

mark on the pilaster/panel plumb line. These

marks represent the hole center line of the stirrup

brackets. Use a level to transfer that mark to all

other plumb lines (“C”).

C

Panel

plumb line

Pilaster plumb line

When installing the partition components,

consult the applicable Mills Partition submittal

drawing for compartment layout dimensions.

1a Layout Dimensions - Continuous Bracket (Optional)

Pilaster centerline: Measure from the

back wall forward to the face of the

compartment, subtract ⁵⁄₈" (16mm) and

mark this location on the floor (“A”). Mark

the same measurement on the opposite

end of your layout (“A1”) and draw a

straight line connecting both marks.

FOR FREESTANDING (FS) PARTITIONS:

Refer to submittal drawings and determine

the approximate location of the outside

panels. Establish dimensions “A” and “A1”

as explained above.

A

Panel centerline: Measure the stall width across the

back wall and place a mark at the base of the rear wall

(“B”). Repeat this step for each panel, starting each

measurement from the last panel centerline (“B1”).

B

Continuous brackets: Draw a plumb line on all walls from each

pilaster and panel centerline. From the highest point in the room,

measure 12½" (318mm) (for stainless steel) or 12¼" (311mm) (for

aluminum) from the floor and place a mark on the pilaster/panel plumb

line. Use a level to transfer that mark to all other plumb lines (“C”).

C

Panel plumb line

64"

(1626mm)

18"

(457mm)

"C"

"C"

"C"

"C"

"C"

"C"

"C"

"C"

"B"

"B"

"B1"

"B1"

"A1"

"A1"

"A"

"A"

"C"