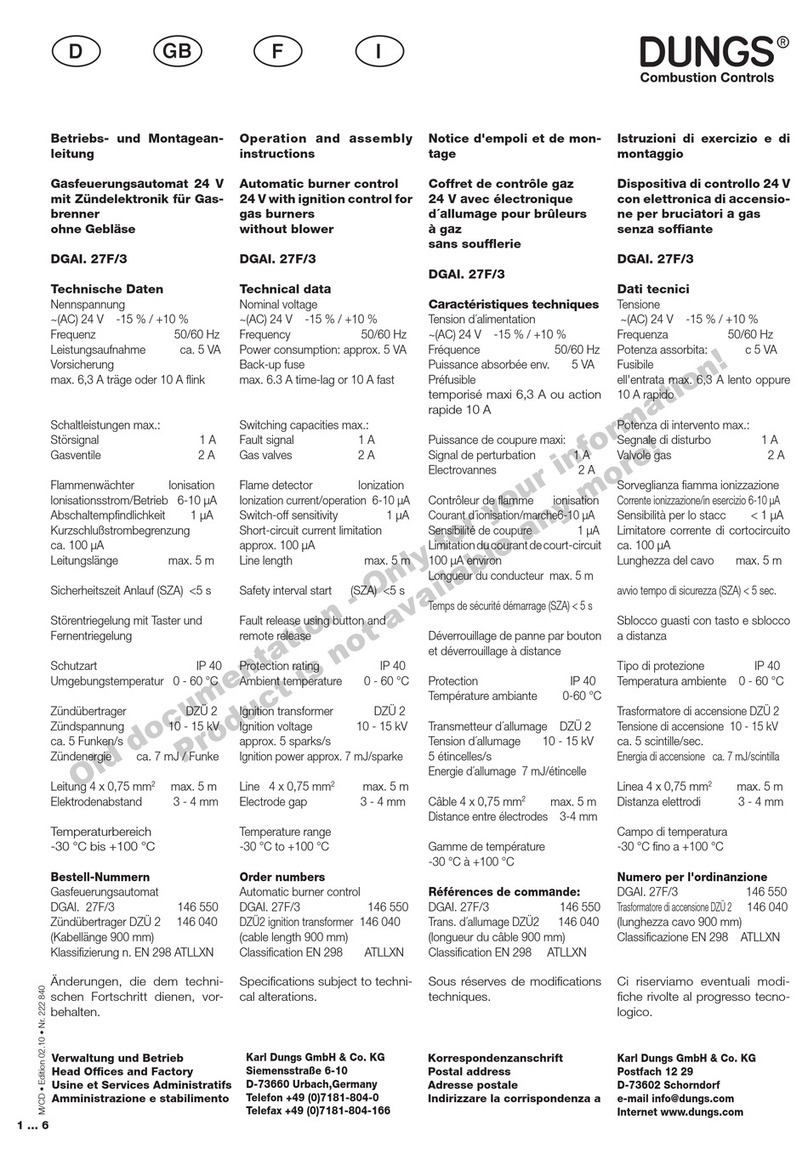

Karl Dungs, Inc

524 Apollo Drive,Suite 10 Lino Lakes, MN 55014 U.S.A.

Phone: (651) 792-8912 Fax: (651) 792-8919 Website: www.dungs.com E-mail: [email protected] 1 … 3

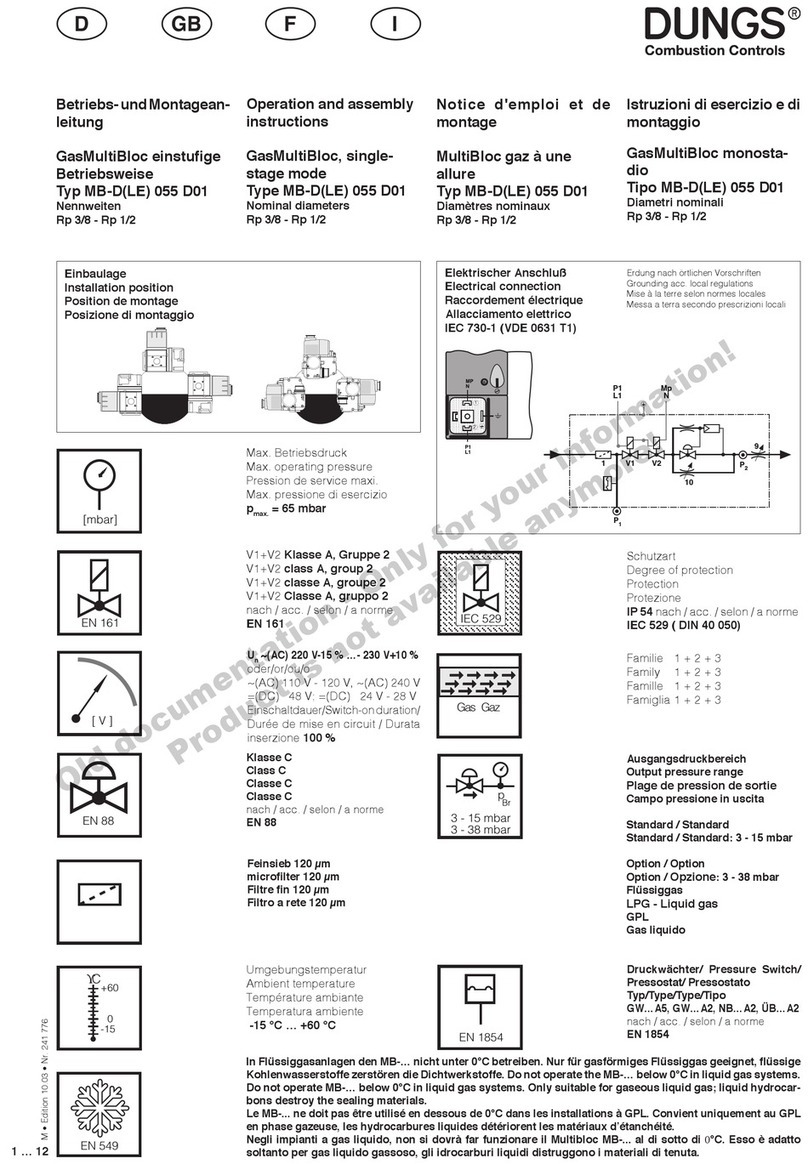

Max. Body Pressure

15 PSI (1000mbar)

Mounting Position

Mulitpoised

Ambient Temperature for DMK

+5° F to +140° F (-15° C to 60° C)

Actuator angle

90 degrees from open to closed

Approvals

UL Listed Component: File No. MH18741

Commonwealth of Massachsetts Approved Product

Approval code G1-1107-35

Max. Contact Rating for Auxiliary Switch

1.5 Amps at 120 Vac 50/60 Hz

Enclosure Rating

NEMA Type 1 enclosure (standard with DMA)

NEMA Type 4 enclosure avaliable (Part #D240 456)

Input Control

4 to 20 mA

Position Feedback or Slave Output

4 to 20 mA; 500 ohm maximum impedance.

Resistence across terminals 8 & 10 is 250 Ohms.

Ambient Temperature Rating

+15 °F to +120 °F (-10 °C to 50 °C)

Approvals

UL Recognized Component: File No. E142163

CSA Certified: File No.157406-1378915

Commonwealth of Massachsetts Approved Product

Approval code G1-1107-35

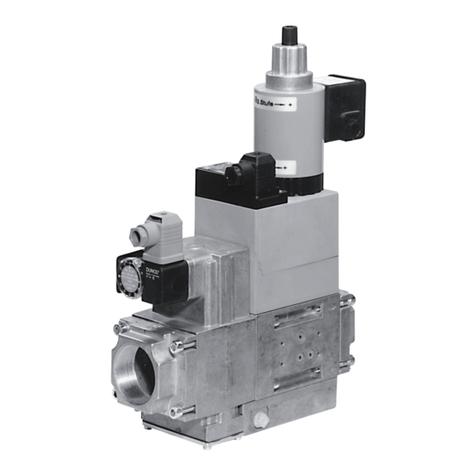

The DMK/6 butterfly control valve actuates from 0 to 90

degrees in either direction; it is not a tight shut-off valve.

Input-side male thread and output-side female thread en-

able assembly directly to DUNGS shutoff valves.

Gases

Natural gas, propane, butane, noncorrosive gases,

and air. Suitable for up to 0.1% by volume, dry H2S.

Max. Pressure

7 PSI (500mbar) MH194167

Max. Differential Pressure

1.5 PSI (100mbar)

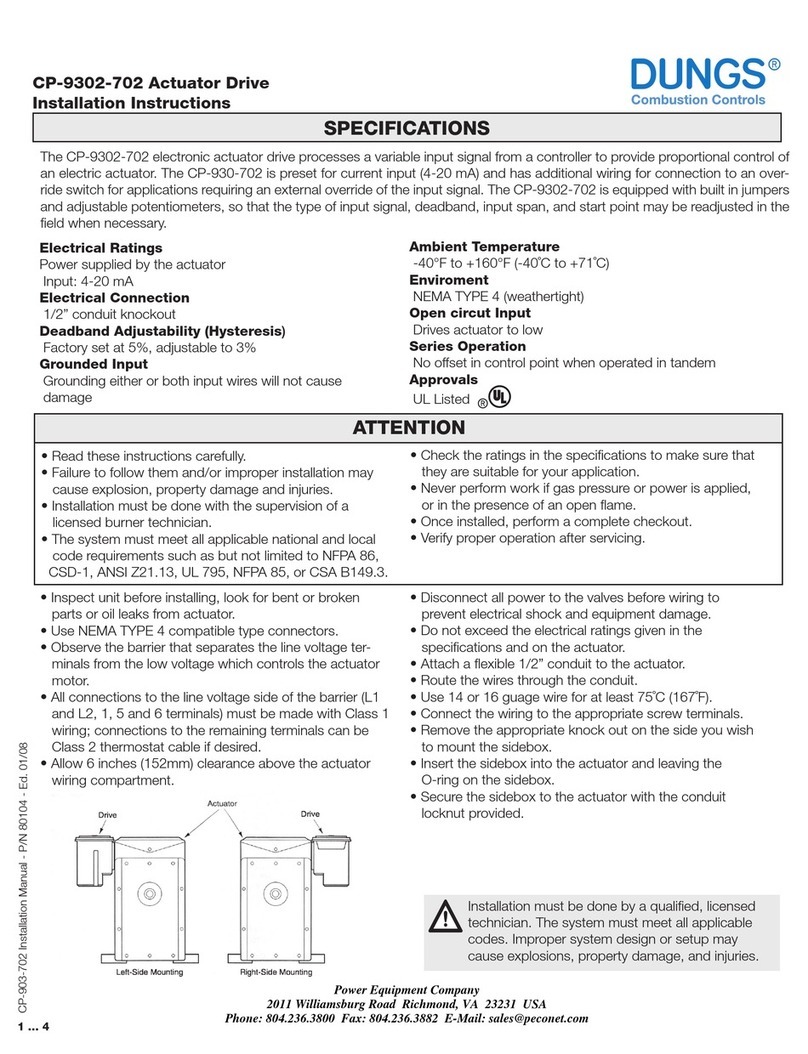

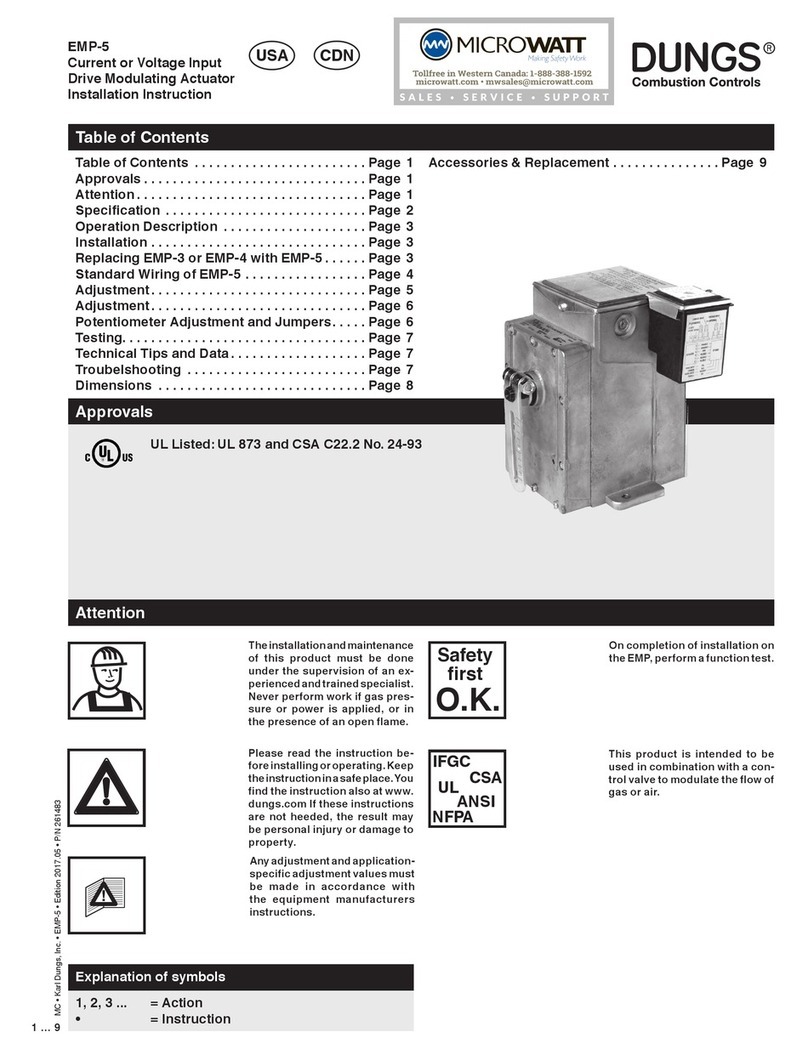

DMA

Motor Actuator

Installation Instructions

The DMA actuator drives from 0 to 90 degrees via 4-20 mA

input signal. It can move in any direction and stop anywhere

over the entire 90 degree stroke.

Electrical Rating

110-120 Vac (+10 / -15%) 50-60 Hz

Max. Power Rating

2.0 VA Holding, 5.4 VA Operating

Max. Torque Ratings

Timing Holding Operating

6 12.4 in-lb 5.3 in-lb

12 24.8 in-lb 8.9 in-lb

30 26.5 in-lb 17.7in-lb

Position Resolution

0.08mA resolution; minimum of 0.45° per step

DMA ACTUATOR SPECIFICATIONS

DMA/DMK Installation Manual - P/N 80118 - Ed. 01/08

DMK/6

Butterfly Control Valve

Installation Instructions

ATTENTION

• Read these instructions carefully.

• Failure to follow them and/or improper installation may

cause explosion, property damage and injuries.

• Installation must be done with the supervision of a

licensed burner technician.

• Check the ratings in the specications to make sure that

they are suitable for your application.

• Never perform work if gas pressure or power is applied,

or in the presence of an open flame.

• Once installed, perform a complete checkout including

leak testing.

• Verify proper operation after servicing.

• The system must be installed, used, and maintaned to

meet all applicable national and local code requirements

such as but not limited to NFPA 86,CSD-1, ANSI Z21.13,

UL 795, NFPA 85, or CSA B149.3.

DMK BUTTERFLY VALVE SPECIFICATIONS

Burnerparts.com

Industrial Combustion Components