4 … 10

M/CD • Karl Dungs Inc. • FRI Gas Pressure Regulator • Edition 2015.02 • P/N 261 400

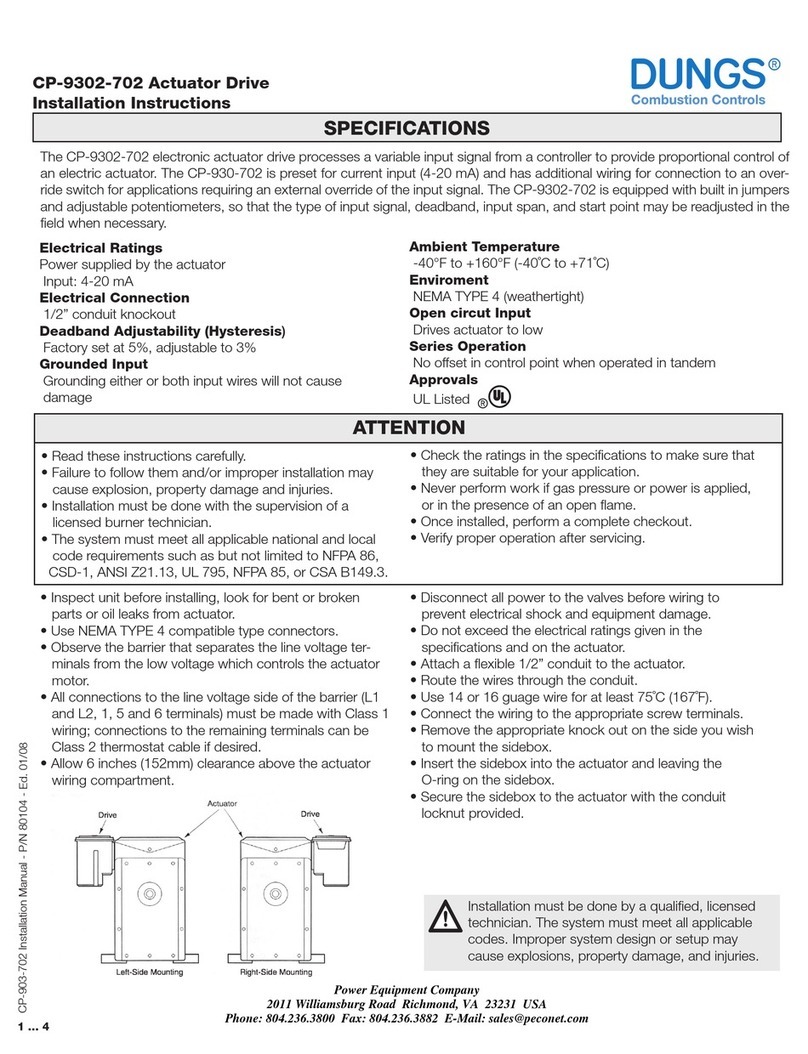

Mounting & Installation

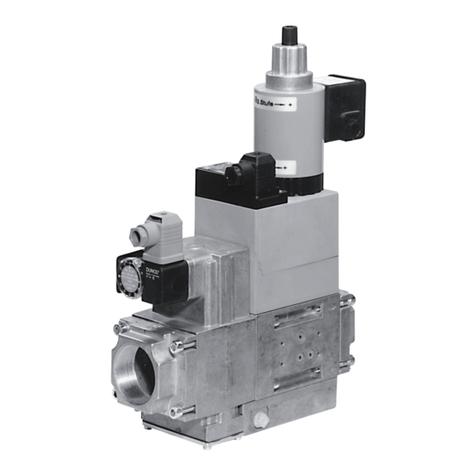

Recommended Procedure to Mount Flanges

1. Makesuretheo-ringsandthegroovesarecleanandin

goodcondition.

2. InstalltheFRI/6withthegasowmatchingthedirection

indicatedbythearrowsonthecasting.

3. MounttheFRI/6verticaluprighttohorizontal.

4. Cleanthemountingsurfaceoftheanges.Makesurethey

areingoodcondition.

5. AttachtheFRI/6totheangesusingtheappropriateM6

orM8socketcapscrewssupplied.

• Theregulatorcanbemountedeitherupstreamordown-

streamoftheDMV.Itcanalsobemountedasastandalone

regulatorusingtwoangesandtheangemountingkit.

• Themaingassupplymustbeshutobeforestartingthe

installation.

• Examinetheregulatorforshippingdamage.

• Theinsideoftheregulatorandpipingmustbecleanand

freeofdirt.

Recommended Procedure to Mount the FRI/6 regulator

to a DMV 701, 702, or 703 series safety shuto valve.

1. Replacetheo-ringinthegrooveonthesideoftheDMV

bodywiththeovalo-ringsuppliedwiththemountingkit.

2. Makesuretheovalo-ringandthegroovearecleanand

ingoodcondition.

3. InstalltheFRI/6regulatorandDMVseriesvalvewiththe

gasowmatchingthedirectionindicatedbythearrows

onthebody.

4. AttachtheregulatortotheDMVseriesvalvebodyusingthe

socketcapcrewssuppliedintheFRI/DMVmountingkit.

5. Usea5mmAllenwrenchfortheFRI705/6&707/6.

6. Usea6mmAllenwrenchfortheFRI710/6&712/6.

7. Tightenthescrewsincrisscrosspattern.

8. Donotovertightenthescrews.Followthemaximumtorque

valueslistedbelow.

9. Afterinstallationiscomplete,performaleaktesttoverify

thatnoleakageoccurs.

Recommended Piping Procedure & Applying Pressure

• Usenew,properlyreamedandthreadedpipefreeofchips.

• Applygoodqualitypipesealant,puttingamoderateamount

onthemalethreadsonly.Ifpipesealantlodgesonthe

regulatorseat,itwillpreventproperoperation.IfusingLP

gas,usepipesealantratedforusewithLPgas.

• Donotthreadpipetoofar.Valvedistortionand/ormalfunc-

tionmayresultfromexcesspipeinthevalvebody.

• Applycounter pressureusinga paralleljawwrenchonly

totheatsontheangewhenscrewingthepipeintothe

anges.

• Donotovertightenthepipe.Followthemaximumtorque

valueslistedbelow.

• Afterinstallationiscompleteandpressureisapplied,per-

formaleaktest.

6. Usea5mmAllenwrenchfortheFRI705/6&707/6.

7. FortheFRI710/6&712/6,theretwooptionsforbolts:

For 1” and 1 1/4” anges, the M8 x 35 mm bolts must

be used.

For 1 1/2” and 2” anges, the M8 x 40 mm bolts must

be used.

8. Tightenthescrewsinacrisscrosspattern.

9. Donotovertightenthescrews.Followthemaximumtorque

valuesbelow.

10.Afterinstallationiscomplete,performaleaktest.

If the ow is not in the same direction of the

arrows the regulator will not operate properly.

Recommended Torque for Piping

” ” 1” 1” 1” 2” NPT

pipe

375 560 750 875 940 1190 [Ib-in]

Recommended Torque for Mounting Screws

M6 M8 Screw Size

62 134 [Ib-in]

Recommended Torque Screws

M6 M8 Screw Size

62 134 [Ib-in]

When rst applying pressure, open the inlet

manual shuto valve slowly. Quickly opening

the inlet manual shuto valve can permanently rup-

ture the internal, balancing diaphragm.