3-4

C) Winterizing: Light should be left in place for winterization.

2-4

120CM MIN.

WATER LEVEL

6.6CM

29.6CM

RIGID CONDUIT

TO POWER SOURCE;

FEED PARAFFIN

CONCRETE MUST BE CUT BACK

AROUND NICHE TO ALLOW FOR

A COMPACT PLASTER SEAL

45CM MIN. FROM WATER LINE

TO TOP OF LENS

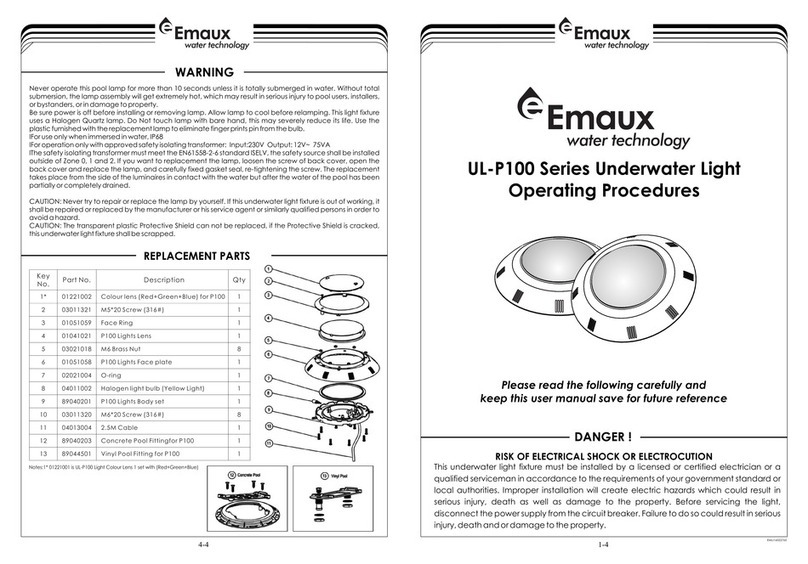

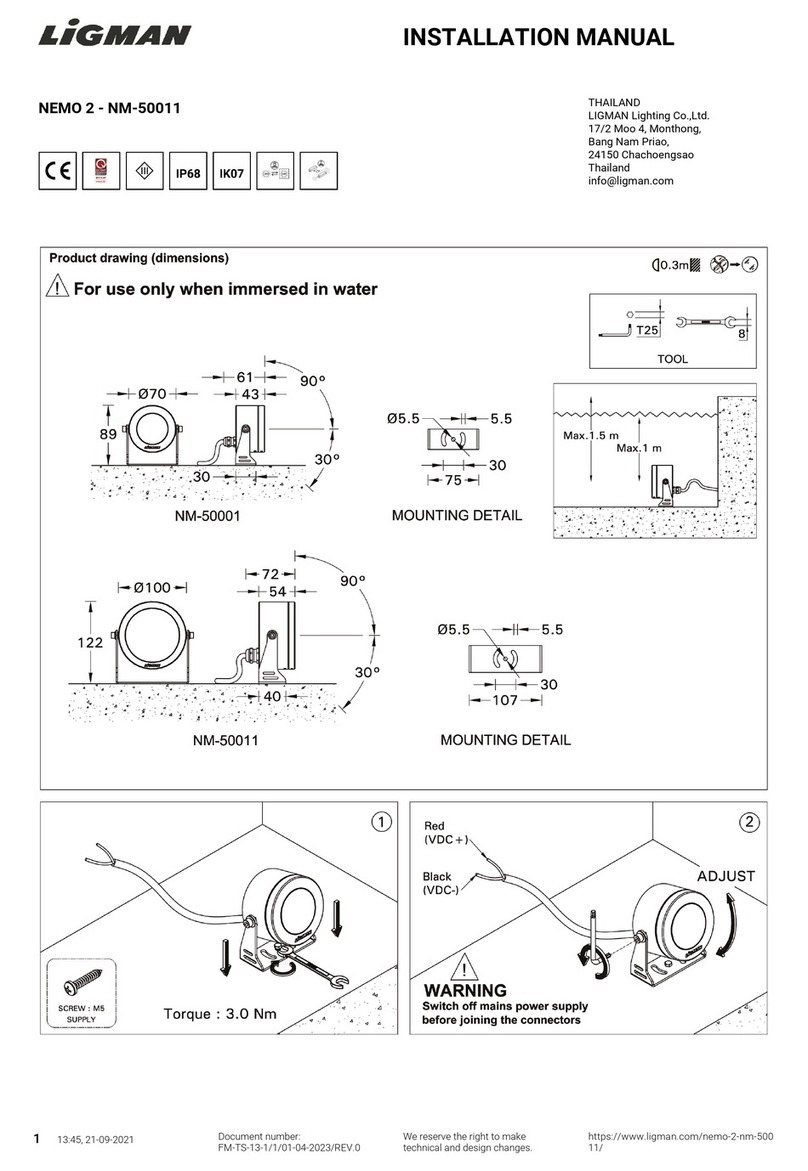

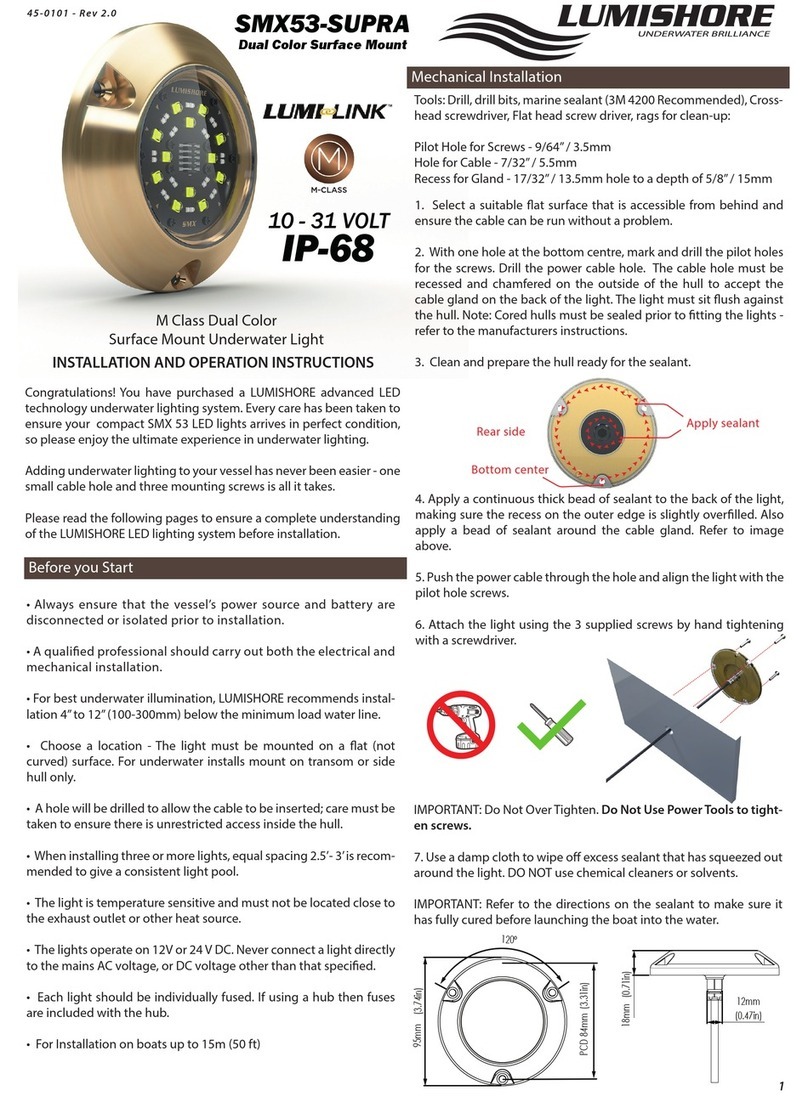

A) Preparatory steps which must be completed by the electrician before light

is installed, see Figure 1.

INSTALLATION

Figure 1.

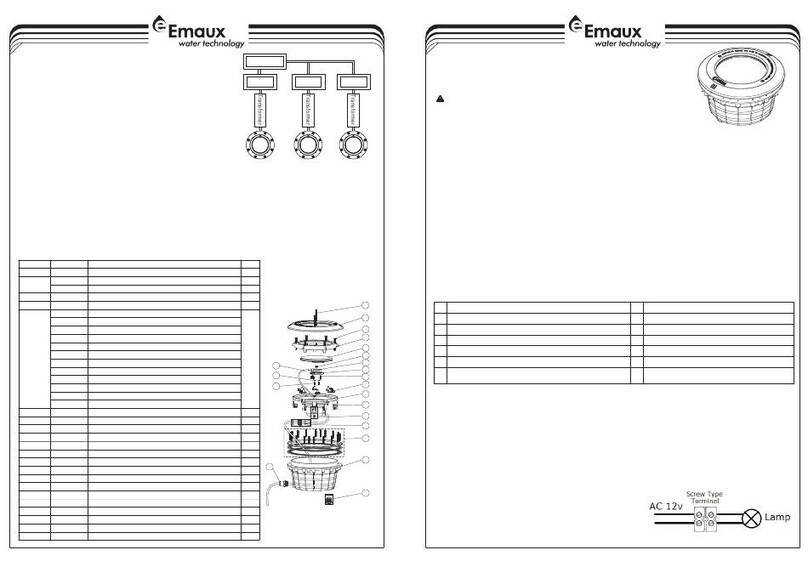

2 Connect conduit to midst of Mounting Spacer (left of Bracket),see Figure 2.

3) If pool surface is to be plastered, you must allow proper concrete cutback for

plaster thickne-ss. Finish concrete surface must be flush with Mounting Spacer.

CAUTION: Finish area surrou-nding Mounting Spacer MUST be flat and flush with the

face of Mounting Spacer, this ensures a snug fit between light and wall, see Figure 3.

4) After pool surface is finished, trim the Conduit.

5) Wrap a length of the cord up to a maximum of 2.4mt long on the back of the light

assembly. This extra cord allows you to bring the light out of the pool for relamping and

servicing.

6) Connect cord electrical wires at Junction box, through Conduit, be careful not to pull

the 75mm-80mm of slack cord at the light through the con-duit when connecting the

wires.

7) Connect all wires to the corresponding circuit wires in the junction box and feed paraffin.

8) Secure the junction box cover in place.

9) Before operating the light for more than 10 sec-onds fill pool until the Underwater Light is

comp-letely submerged in water. To check for proper operation turn on main switch

or circuit breaker as well as the switch that operates the Underwater Light itself.

10) Rotating Locking System ensures light is sec-ured to bracket, see Figure 4.(Figure 5.)

)

B) Perform the following steps after the electrical system requirements are met.

1 Locate position on a vertical wall where light is to

plate must be 45 cm below normal water level, see Figure 1.

) Be installed. The edge of the face

FOR FIBREGLASS POOL, PRE-FAB

MODULAR POOL AND VINYL LINER POOL

Figure 3.

Figure 2.

DO NOT MOUNT ON:

REVERSE RADIUS

SURFACE

IRREGULAR OR

UNEVEN SURFACES

DO MOUNT ON:

FLAT

SURFACE

WALLS WITH NO TIGHTER

THAN 6 FT. RADIUS AS

VIEWED FROM TOP

MOUNTING BRACKET

CONDUIT

LIGHT

Figure 4.

O P E N

P O S I T I O N

L O C K

P O S I T I O N

F O R C O N CR E T E P O O L

O P E N

P O S I T I O N

L O C K

P O S I T I O N

Figure 5.

F O R F I B RE G L A S S P O O L,

P R E - F AB M O D U L A R P O OL

A N D V I N YL L I N E R P O O L

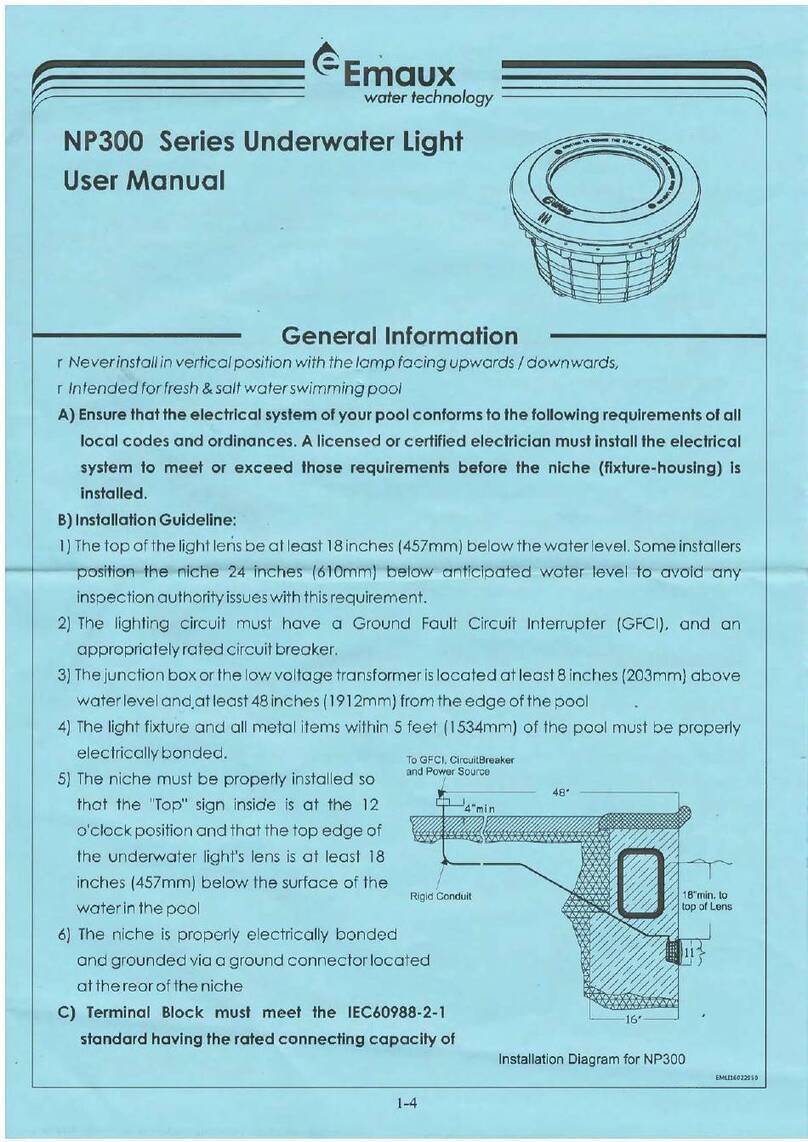

1) Ensure that the electrical system and its wiring for the pool conform to the requirements

of your govenment or your local authorities. The installa-tion of the Underwater Light

should only be per-formed by a licensed electrician.

a) The junction box, or the low voltage transfor-mer for 12 volt Underwater Light model is

to be located at least 120cm from the edge of the pool, see Figure 1.

b) The light fixture and all metal parts that are within 240cm of the pool must be properly

protected with non-ductile materials and that the connections must be waterproof.

c) The mounting bracket must be properly instal-led so that the top edge of the

Underwater Light lens is at least 45cm below the surface of the water in the pool, see

Figure 1.

2) Consult the local Government Building Departm-ent to be certain that the pool's

electrical system meets all applicable requirements.