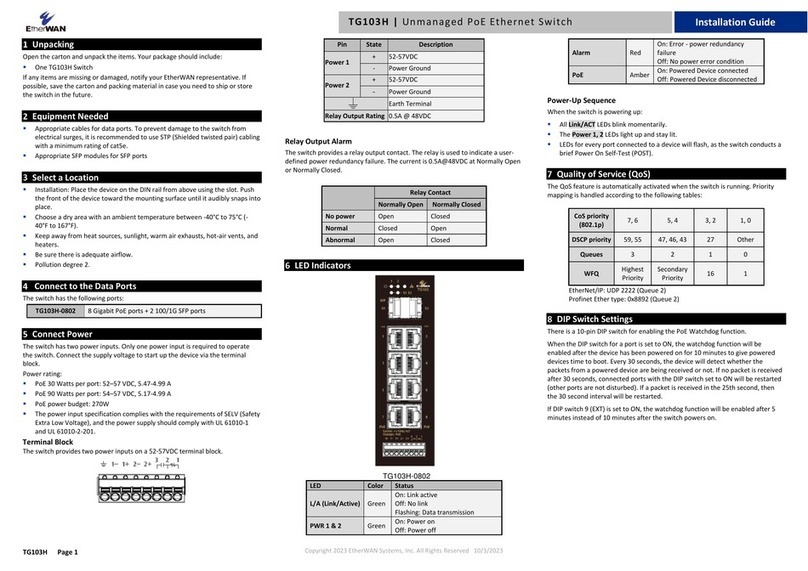

To enable digital input alarms globally:

1. Choose Enable from the drop down menu in the Set State field.

2. Click on the Update Setting button to the right of the field.

To enable specific digital input alarms:

1. Enter a name or description of the alarm in the Description field.

2. In the Alert field, choose Enable/High from the drop-down menu if you want

the alarm to trigger in an occurrence of high voltage (wet contact), or Open state

(dry contact). Choose Enable/Low if you want the alarm to trigger in an

occurrence of low voltage (wet contact), or Closed to ground state (dry contact).

3. To set alarms for temperature and humidity, enter the threshold value in the

field provided, and select Enable from the drop down menu at the right.

4. Click on the Update Setting button at the bottom right to put the new settings

into effect. Then navigate to the Email configuration page.

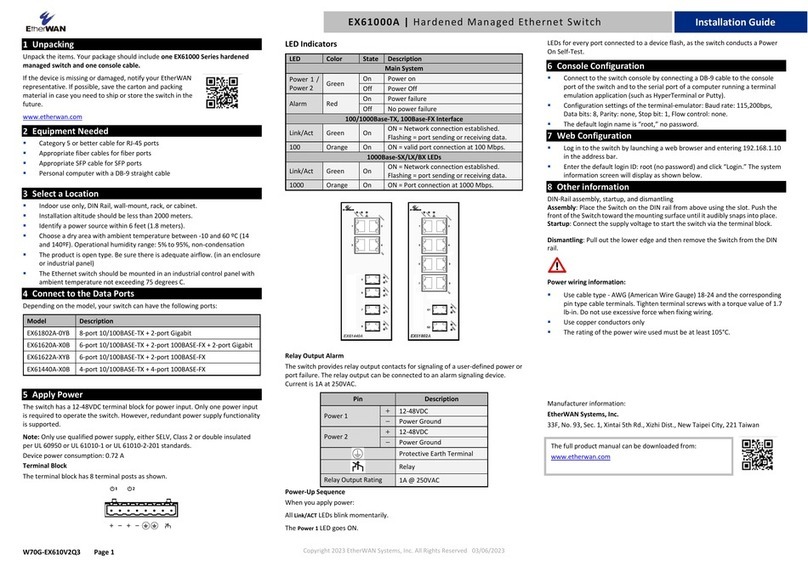

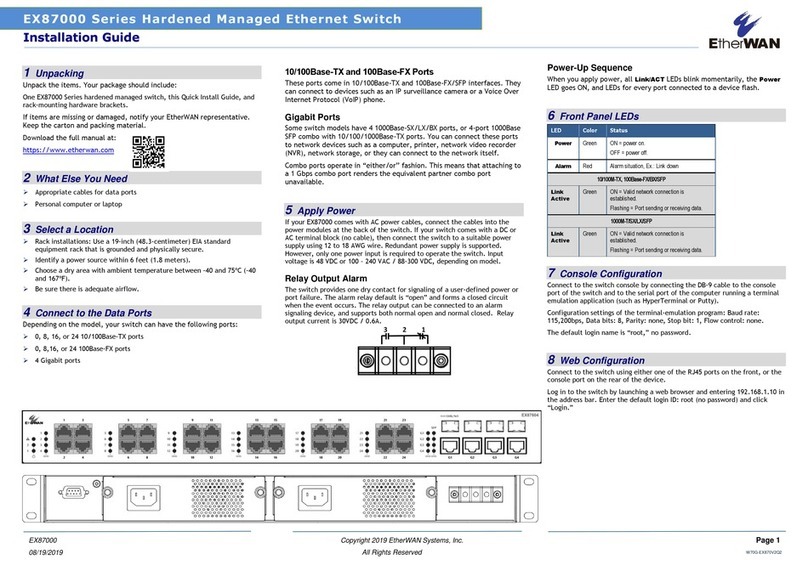

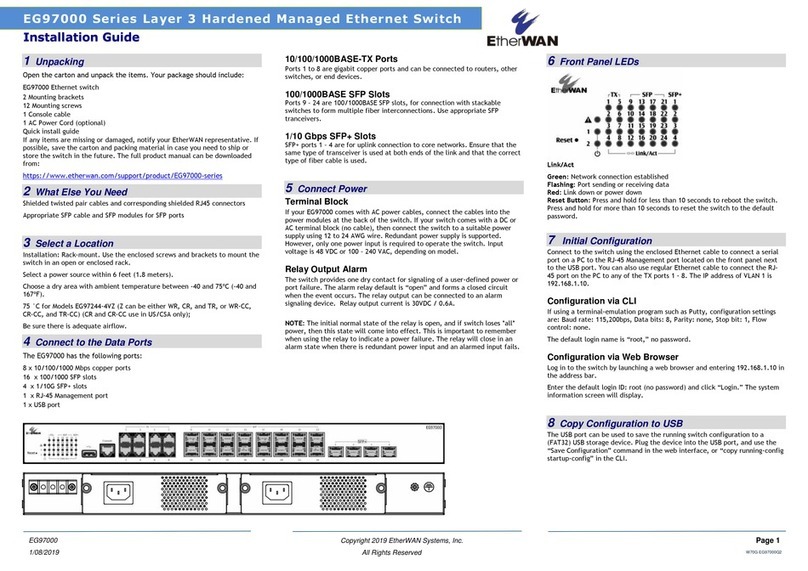

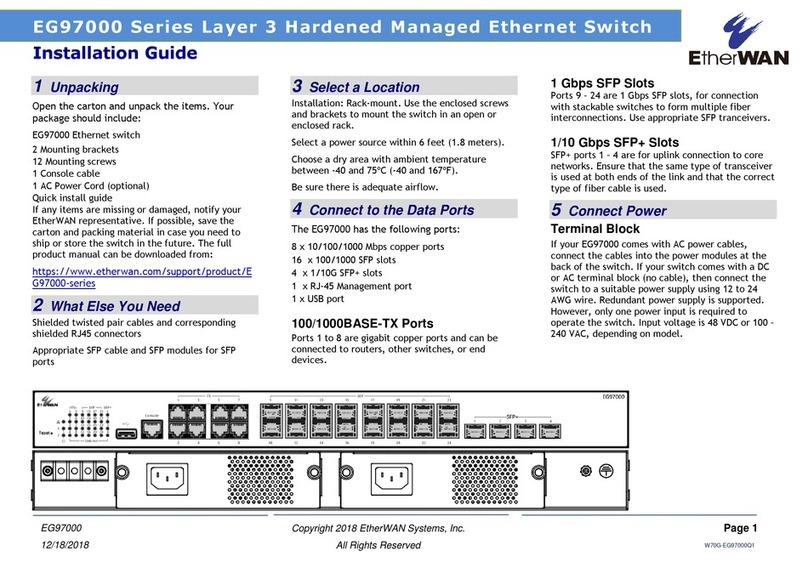

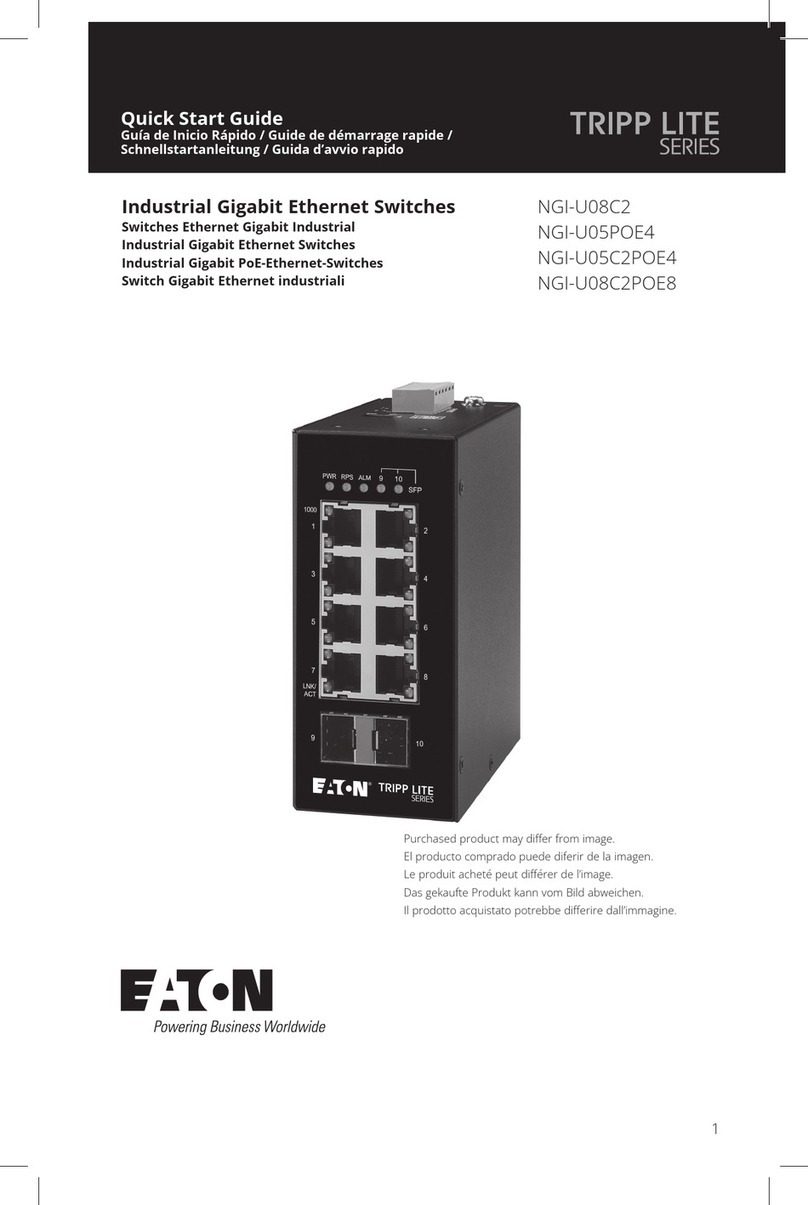

Console Configuration

Connect to the switch console by connecting the DB-9 cable to the console port of

the switch and to the serial port of the computer running a terminal emulation

application (such as HyperTerminal or Putty).

Configuration settings of the terminal-emulation program: Baud rate:

115,200bps, Data bits: 8, Parity: none, Stop bit: 1, Flow control: none.

The default login name is “root,” no password.

Web Configuration

Connect to the switch using either one of the RJ45 ports on the front, or the

console port on the rear of the device.

Log in to the switch by launching a web browser and entering 192.168.1.10 in the

address bar. Enter the default login ID: root (no password) and click “Login.”

Copy Configuration to USB

The switch is equipped with one USB port (Type A connector) for configuration

file and syslog backup. The USB port can be used to save the configuration and

Syslog to a (FAT32) USB storage device.

Plug the device into the USB port, and use the “Save Configuration” command in

the web interface, or “copy running-config startupconfig” in the CLI.

Safety Information

This equipment is intended to be used in a restricted access location and by

qualified personnel. This equipment is not suitable for use in locations where

children are likely to be present.

Pluggable optical modules and direct-attach cables shall meet the following

regulatory requirements:

• UL and/or CSA registered component for North America

• Class 1 Laser Product

• FCC 21 CFR Chapter 1, Sub-chapter J in accordance with FDA & CDRH

requirements

• IEC/EN 60825-1:2014, IEC/EN 60825-2:2004+A1+A2 or later, European Standard

(A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may be

greater than room ambient. Therefore, consideration should be given to installing

the equipment in an environment compatible with the maximum ambient

temperature (Tma).

B) Mechanical Loading - Mounting of the equipment in the rack should be such

that a hazardous condition is not achieved due to uneven mechanical loading.

C) Circuit Overloading - Consideration should be given to the connection of the

equipment to the supply circuit and the effect that overloading of the circuits

might have on overcurrent protection and supply wiring. Appropriate

consideration of equipment nameplate ratings should be used when addressing

this concern.

D) Reliable Earthing - Reliable earthing of rack-mounted equipment should be

maintained. Particular attention should be given to supply connections other than

direct connections to the branch circuit (e.g. use of power strips).

Do not disable the power cord grounding plug. The grounding plug is an

important safety feature.

Les matériels sont destinés à être installés dans des EMPLACEMENTS À ACCÈS

RESTREINT.

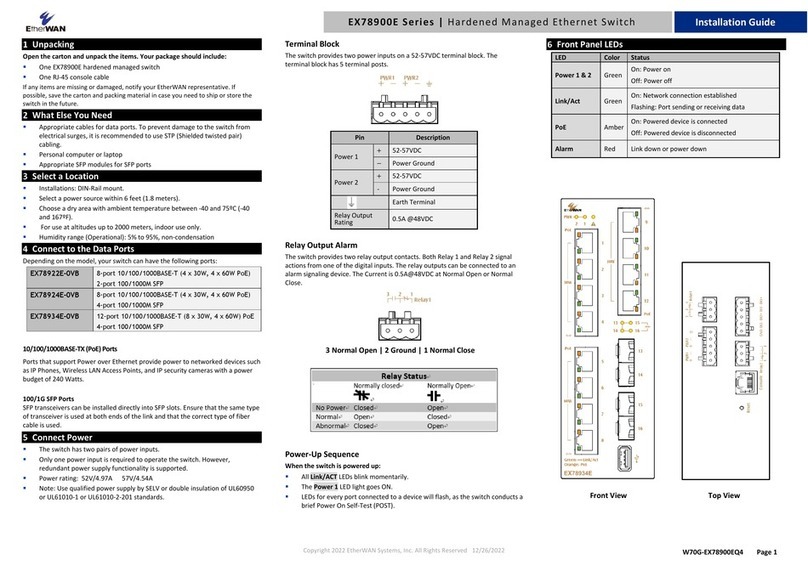

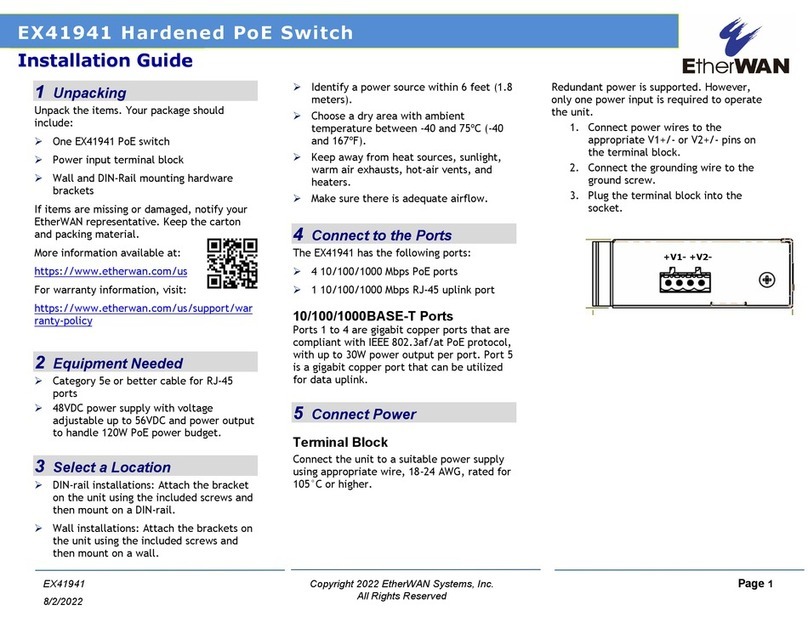

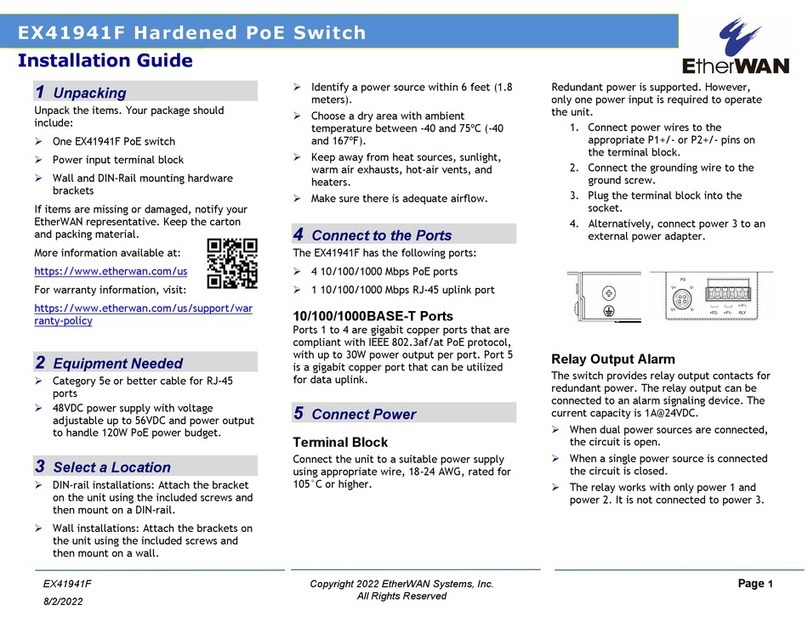

Power wiring information:

The rating of the power wire used must be at least 105°C.

USE COPPER CONDUCTORS ONLY.

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

WARNING –Explosion hazard. Do not disconnect the terminal block while the

circuit is live or unless the area is known to be free of ignitable concentrations.

For repair or maintenance needs, contact EtherWAN directly.

Informations de câblage d'alimentation:

Le calibre du fil d'alimentation utilisé doit être d'au moins 105°C.

DESTINÉ À ÊTRE UTILISÉ AVEC DES CONDUCTEURS EN CUIVRE SEULEMENT.

Si la méthode d'utilisation de l'équipement diffère de celle décrite par le fabricant,

la protection assurée par l'équipement risque d'être altérée.

Contactez-nous pour l'entretien ou la reparation.

Manufacturer information:

EtherWAN Systems, Inc.

33F, No. 93, Sec. 1, Xintai 5th Rd., Xizhi Dist., New Taipei City, 221 Taiwan