Hanil Smart R17 User manual

Table of contents

Other Hanil Laboratory Equipment manuals

Hanil

Hanil Supra R17 User manual

Hanil

Hanil M 13 User manual

Hanil

Hanil FLETA 4 User manual

Hanil

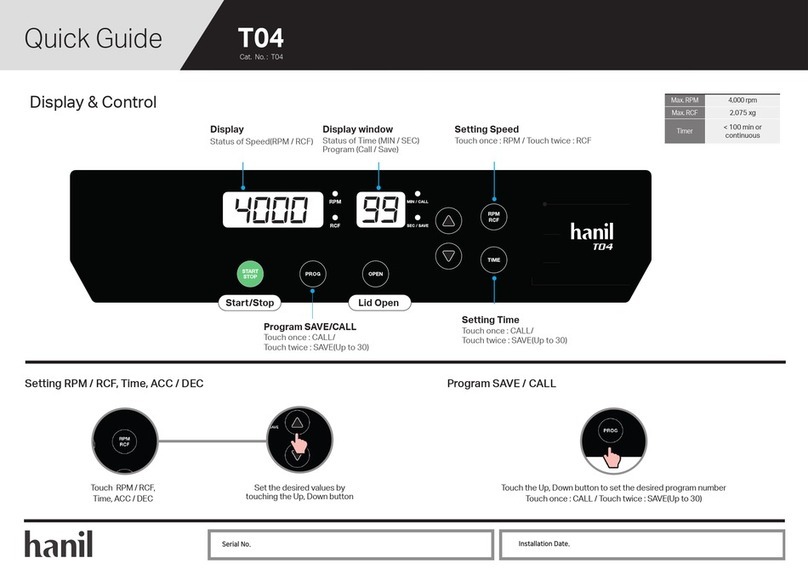

Hanil T04 User manual

Hanil

Hanil T04B User manual

Hanil

Hanil Supra R30 User manual

Hanil

Hanil M15S User manual

Hanil

Hanil Smart 15 Plus User manual

Hanil

Hanil Smart 13 User manual

Hanil

Hanil HyperVAC HVC-2124 User manual

Hanil

Hanil T04 User manual

Hanil

Hanil Ultra 5.0 User manual

Hanil

Hanil Fleta 5 User manual

Hanil

Hanil ARA Smart 6 User manual

Hanil

Hanil T05R User manual

Hanil

Hanil J1250 User manual

Hanil

Hanil Ultra 5.0 User manual

Hanil

Hanil Cellspin II User manual

Hanil

Hanil Micro 12 User manual

Hanil

Hanil Fleta5 User manual

Popular Laboratory Equipment manuals by other brands

Lovibond

Lovibond TC Series instruction manual

Response Biomedical

Response Biomedical RAMP 200 user manual

BIOMET

BIOMET OPTIVAC VACUUM MIXING SYSTEM Instructions for use

OfiTE

OfiTE MB HTHP instruction manual

Miele

Miele PG8582 CD Installations plan

Agilent Technologies

Agilent Technologies Labware MiniHub G5584A user guide

Sturdy

Sturdy SA-300MA instruction manual

Terra Universal

Terra Universal Smart Desiccator Installation and operating guide

Dionex

Dionex ICS-90 Operator's manual

diagenode

diagenode B01060002 user manual

Centurion Scientific

Centurion Scientific Pro-Research instruction manual

Metrohm

Metrohm 761 SD Compact IC Instructions for use