Hioki MEMORY HiCORDER 8855 Instruction manual

Other Hioki Test Equipment manuals

Hioki

Hioki 3541 User manual

Hioki

Hioki MEMORY HiCORDER 8855 User manual

Hioki

Hioki 3280-10 User manual

Hioki

Hioki BT3564 User manual

Hioki

Hioki 3169-21 Instruction manual

Hioki

Hioki IR4053 User manual

Hioki

Hioki 3560 User manual

Hioki

Hioki ST5680 User manual

Hioki

Hioki 3257-50 User manual

Hioki

Hioki 3288 User manual

Hioki

Hioki ST5680 User guide

Hioki

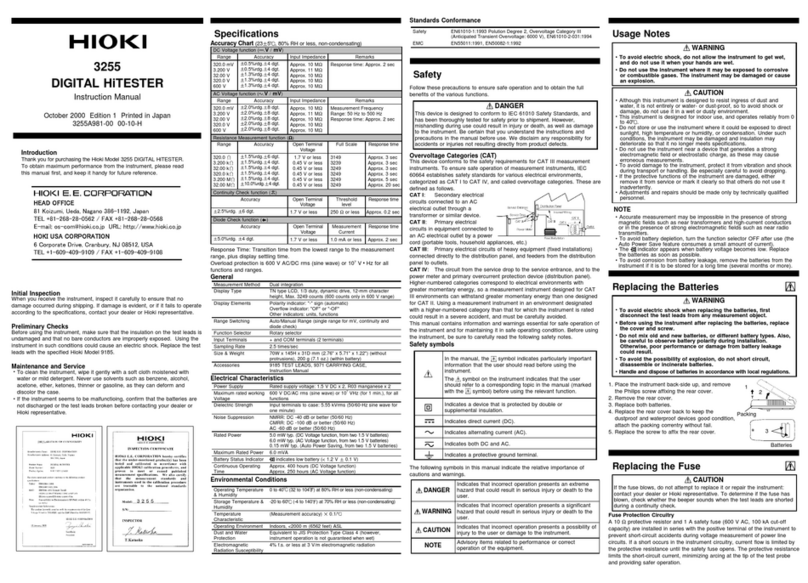

Hioki 3255 User manual

Hioki

Hioki 7016 User manual

Hioki

Hioki FT3151 User manual

Hioki

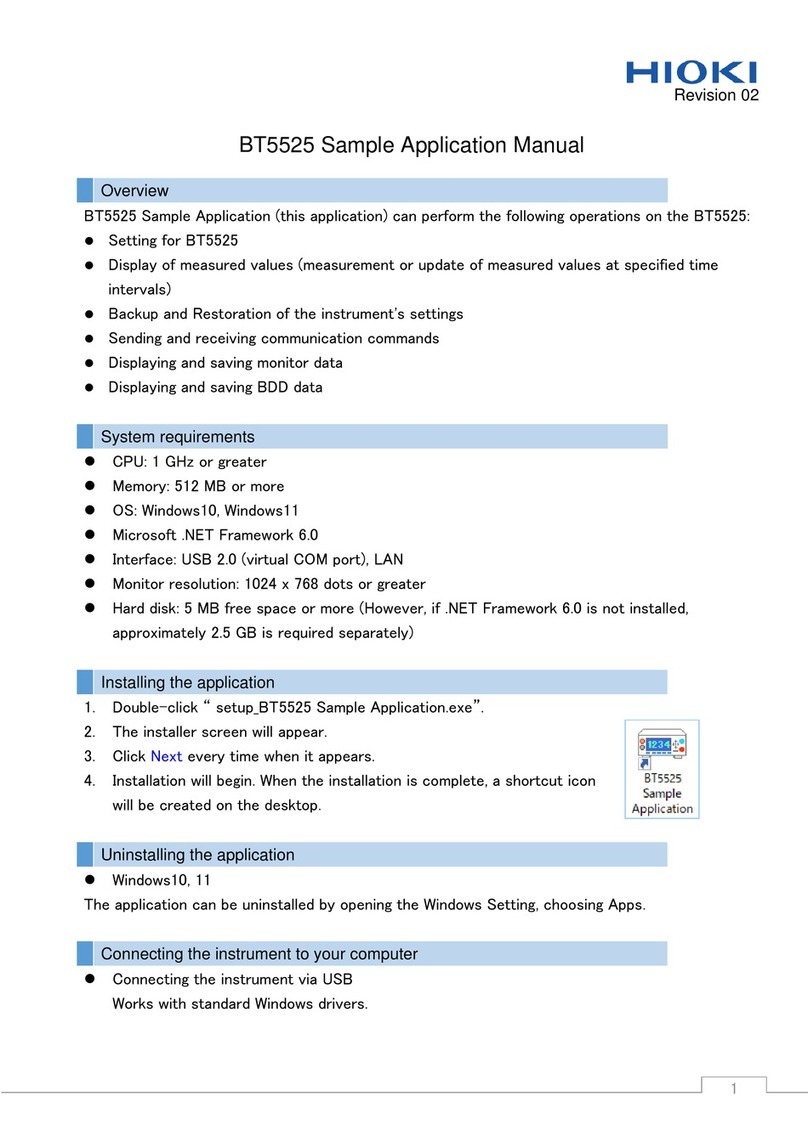

Hioki BT5525 Instructions for use

Hioki

Hioki 3285-20 User manual

Hioki

Hioki 3154 User manual

Hioki

Hioki TS2400 User manual

Hioki

Hioki CLAMP ON LEAK HiTESTER 3283 User manual

Hioki

Hioki ST5680 User manual