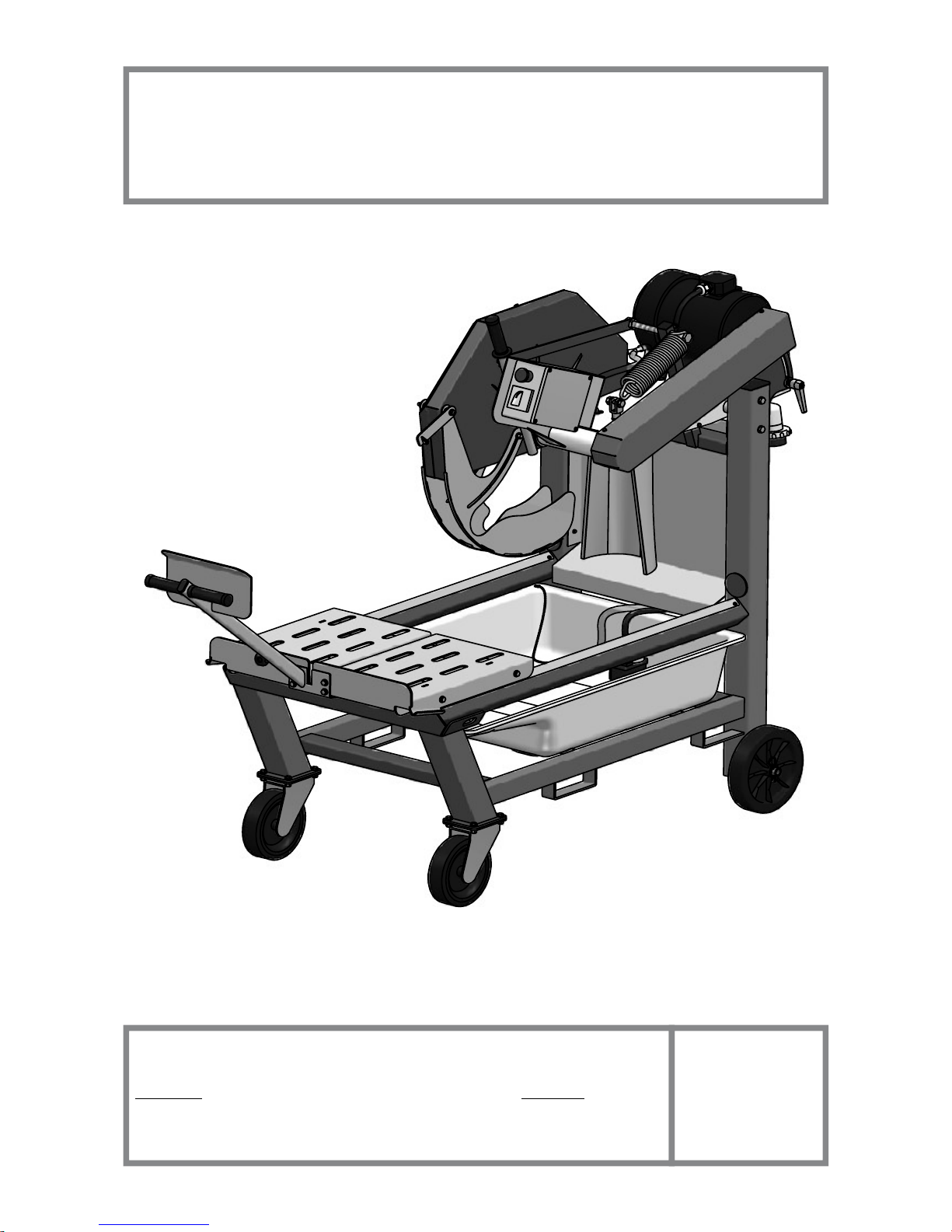

IMER MASONRY 700 Guide

MASONRY 700

SAWING MACHINE

OPERATING, MAINTENANCE, SPARE PARTS MANUAL

IMER WEST

3654, Enterprise Avenue

Hayward, CA 94545

Ph. 510.670.7970

Fax 510.783.4255

IMER EAST

221 Westhampton Place

Capitol Heights, MD 20743

Ph. 301.336.3700

Fax 301.336.6687

IMER

U.S.A. Inc.

Toll Free: 800.275.5463

www.imerusa.com

2010/07 - R04

Cod. 3228131

IMER U.S.A. Inc.

MASONRY 700

2

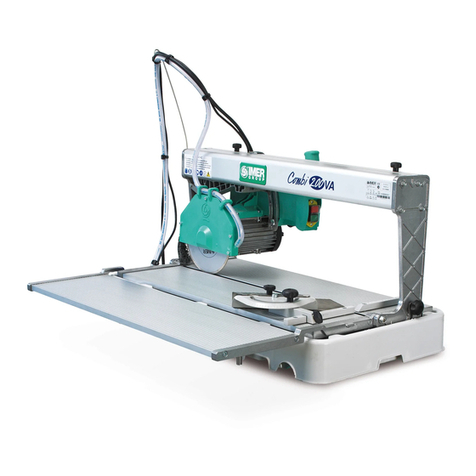

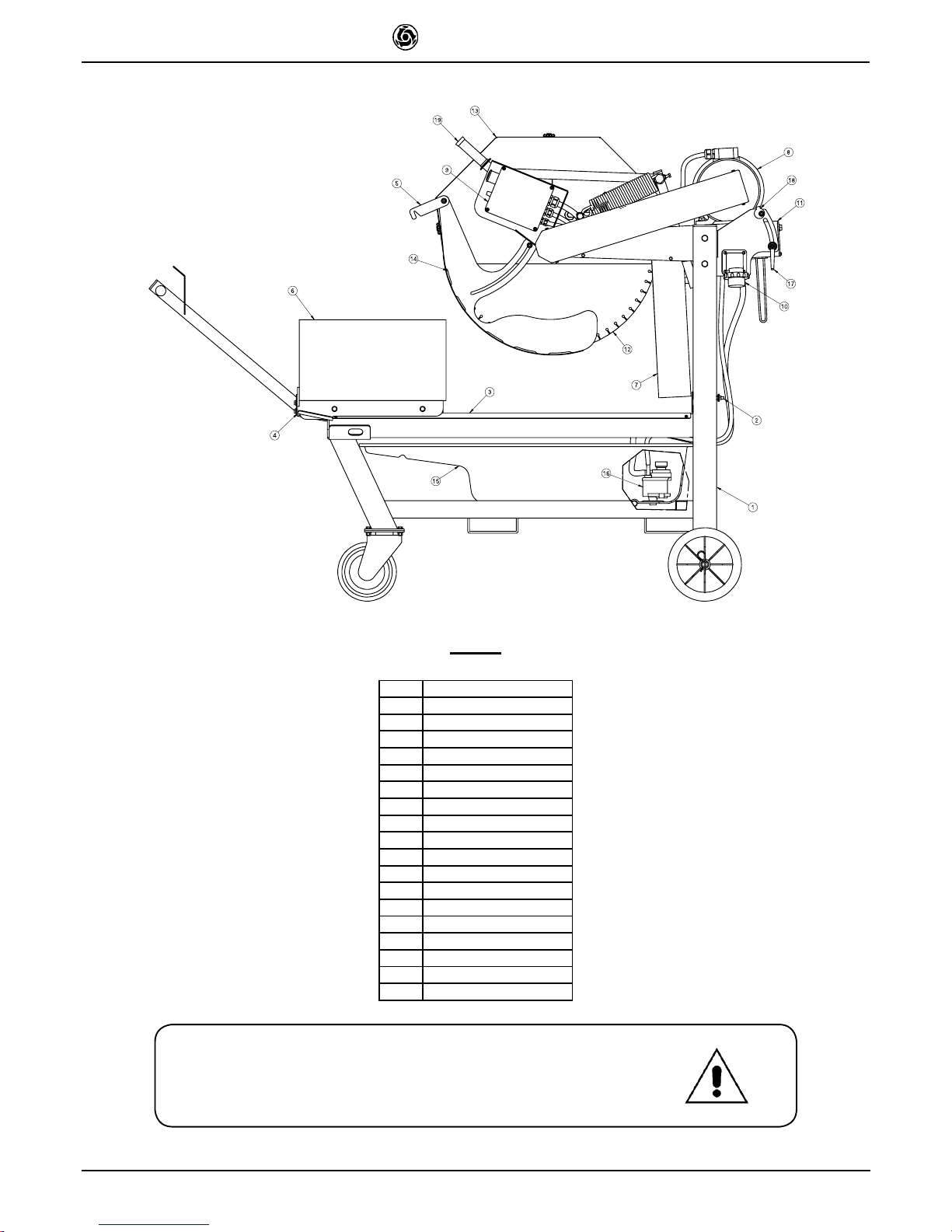

FIG. 1

REF.

DESCRIPTION

1

Frame

2

Screw

3

Guide bar

4

Carriage

5

Trolley clamping

6

Workpiece

7

Spray guard

8

Motor

9

Junction box

10

Plug

11

Cutting head group

12

Blade

13

Disc cover

14

Blade cover

15

Drum

16

Water pump

17

Adjusting cut lever

18

Cam

Special attention must be given to warnings with this symbol:

IMER U.S.A. Inc.

MASONRY 700

3

Dear Customer,

Congratulations on your choice of purchase: this IMER saw, the result of

years of experience, is a fully reliable machine and is equipped with the

latest technical innovations.

- WORKING IN SAFETY

To work in complete safety, read the following instructions care-

fully.

This OPERATION AND MAINTENANCE manual must be kept on site

by the person in charge, e.g. the SITE FOREMAN, and must always be

available for consultation.

This manual is to be considered an integral part of the machine, and

it must be preserved for future reference (EN 12100/2) throughout the

cement may be requested from the saw manufacturer.

The manual contains important information regarding site preparation,

installation, machine use, maintenance procedures and requests for

spare parts. Nevertheless, the installer and the operator must both have

adequate experience and knowledge of the machine prior to use.

To guarantee complete safety of the operator, safe operation and long

life of equipment, follow the instructions in this manual carefully, and

observe all safety standards currently in force for the prevention of

accidents at work. Use personal protection (safety footwear, suitable

clothing, gloves, goggles, etc.).

- The use of protective goggles is compulsory.

- Ear protection must be worn at all times.

- Make sure that warning signs are always legible.

the steel structure or working parts of the machine.

IMER INTERNATIONAL declines all responsibility for non-compliance

with laws and standards governing the use of this equipment, in par-

ticular; improper use, defective power supply, lack of maintenance,

instructions contained in this manual.

IMER INTERNATIONAL is entitled to modify the characteristics of the

sawing machine and/or the contents of this manual without necessarily

updating previous machines and/or manuals.

1. TECHNICAL DATA

2.

Table 1 - TECHNICAL DATA

Model

Masonry 700

Blade diameter

700 mm

Blade mounting hole

25,4 mm

Blade rpm (220V/60Hz) single-phase

Blade rpm (220V/60Hz) three-phase

1220 rpm

1710 rpm

Blade rotation direction

clockwise

Motor rating 220V/60Hz single-phase

Motor rating 220V/60Hz three-phase

4 kW

5.5kW

Cutting table dimension

490x660 mm

Overall dimensions

(width x length x height)

850x1550x1600 mm

Overall dimensions for transport

(width x length x height)

850x1550x1600 mm

Sawing machine operating weight 285 Kg

Weight for transport

202 Kg

Table 2

Feature

Motor (220V/60Hz)

three-phase

Motor (220V/60Hz)

single-phase

Power (kW)

5.5

4

Rated voltage (V)

220 220

Frequency (Hz)

60 60

Absorbed current

(A)

22

23.2

rpm

1710 1220

Service type

S1 S1

Insulation category

F F

Protection category

IP55 IP55

180

2. DESIGN STANDARDS

The MASONRY 700 sawing machine has been designed and manu-

factured in accordance with the following standards: EN 12100-1-2; EN

12418 and meets directives 89/336/EEC; 98/37/CE.

3. SOUND PRESSURE LEVEL AND VIBRATIONS

Table 3 shows the sound pressure level measured loadless at the ope-

PA

) and of the vibrations transmitted during operation.

Table 3

Model

Type of motor

L

pA

A

eq

Masonry 700

Electric 95 dB

2.33 m/s

2

4. CUTTING SPECIFICATIONS

This saw model has been specially designed for cutting stone, ceramics,

marble, granite, concrete and similar materials. Only water-cooled dia-

mond blades with continuous or segmented edges must be used. Under

no circumstances must dry cutting blades be used or materials other

sponsibility for damage caused by improper use of the above machine.

5. CUTTING CAPACITY

(Blade diameter 700 mm)

movement of the disk).

6. WARNING

(max. 40 kg)

wheels with the brake before starting cutting operations.

case, workpieces must not overhang the worktable.

cooling water contaminated with cutting dust.

7. SAFETY PRECAUTIONS

IMER saws are designed for work on construction sites and under con-

ditions of natural light, hence the workplace must be adequately lit (min

500 lux).

- It must never be used in environments where the danger of

devices, which must be in perfect condition.

2. Never use makeshift and/or faulty power cables.

3. Make electrical connections on the construction site where they

will not be subject to damage. Never stand the saw on power sup-

ply cables.

4. Lay power cables in such a way as to prevent water penetration.

5. Repairs to electrical installations must only be carried out by

nected from the power supply and is completely immobile during

repairs and maintenance operations.

earth system with a copper plait with a minimum cross

section of 16 mm

2

. The connection point is made with

with the earth symbol.

- Stop the saw only by means of the main switch

8. ELECTRICAL SAFETY

The IMER saw meets Std. EN 60204-1, EN 61029-1 and is in particular

IMER U.S.A. Inc.

MASONRY 700

4

9. TRANSPORTATION

- Before removing the panel saw, lock the carriage using the

ting the machine with a fork lift, insert the left fork in the slot provided

surfaces as follows:

1. make sure that the front wheel brakes are released.

2. make sure that the piece holder carriage is clamped with the special

3. pull the machine by hand using the piece holder carriage grip; move-

ment (also round corners) is facilitated by the front castor wheels.

10. INSTALLATION

1. Install the machine on a completely even and stable surface.

2. Block the front wheels with the brakes.

3. Release the carriage from the lever that secures it to the frame (ref.4,

11. ELECTRICAL MAINS CONNECTION

- Make certain that a residual current device and miniature

circuit breaker are installed on the electrical power line.

11.1 Connecting versions with motor 115V/60Hz

Ensure that the supply voltage corresponds to machine dataplate speci-

- To supply the machine it is necessary to use a 2-pole +

ground cable in order to ensure the machine's connection to the

site's equipotential system.

11.2 Connecting versions with motor 220V/60Hz

Ensure that the supply voltage corresponds to machine dataplate speci-

- To supply the machine it is necessary to use a 3-pole +

ground cable in order to ensure the machine's connection to the

site's equipotential system.

11.3 Sizing the power supply cable

The power supply line must be suitably sized to prevent voltage drops.

Do not use cable winders. The electric cable wire size must take into

account the operating currents and length of the line to avoid excessive

voltage drops (table 4).

Table 4

Model

Type of motor

1.5 2.5 4.0

Masonry 700

Single-phase

Masonry 700

Three-phase

220 V

23.2 A

0 - 12

13 - 24 25 - 50

220 V

22 A

0 - 12

13 - 24 25 - 50

sheathing that is resistant to wear, crushing and extreme weather condi-

tions (for example H07RN-F).

- All power supply installations must comply with CEI 64-8

standards (harmonised document CENELEC HD384).

12. MACHINE START-UP

Before connecting the machine to the power supply:

1. Ensure that the metal structure is connected to an earthing plant as

90 L).

3. Ensure that the power circuit corresponds to the requirements as in-

4. Connect the machine to the power supply

5. Turn the start-stop selector to the start position (star connection). Wait

for 5 sec. and turn to the running position (delta connection).

6. Check that the direction of blade rotation corresponds to that indica-

ted by the arrow on the blade guard.

the direction of rotation of the disk is the opposite of the arrow on

the protective guard, disconnect the power socket from the plug

on the machine and invert a phase. To do this, exchange the two

mobile terminals on the poles using a screwdriver. This operation

is carried out without removing the plug working on the rotary ele-

ment that holds the mobile poles.

guard (do not perform cutting without water).

8. If all is in order, proceed with cutting.

13. EMERGENCY STOP

- In the case of an emergency, stop the machine pressing the

special red mushroom button. To start again, reset the mushroom

button turning it clockwise and turn the selector to zero, then re-

14. BLADE INSTALLATION

2.Release the spring catches clamping the disk mobile guard (ref. 3,

thread).

- Never use worn blades or blades with missing segments.

- Only use blades that are designed for the number of revolu-

tions indicated on the machine rating plate.

- Check that the direction of rotation of the disk is as shown

on the disk guard.

counter-clockwise (left-hand thread).

7. Put the water pipe back in place and tighten the fastener until the pipe

Fig. 6

- Ensure that the blade guard (ref.3) is locked securely into

position.

tightened can provoke damage to the machine

or injury to persons.

- Note that the blade must have an external

diameter of 700 mm, a central hole diameter of

25.4 mm and max. thickness of 4 mm.

- Check that the blade to be used is suitable

for the material to be cut.

15. USE

- Leave a space of 150 cm around the machine to operate in

full safety.

explosions.

dling.

- Ensure correct installation of all protective devices.

never necessary: N.B. the pump suction hose must always remain im-

mersed in water.

- For safety purposes the removal of protective guards from

the machine is strictly prohibited.

- The machine is protected against overload: this protection

triggers stopping the machine, after which the time necessary for

the overload to cool must pass before it is possible to restart the

machine.

- To resume work after a voltage cut-off, turn the selector to

IMER U.S.A. Inc.

MASONRY 700

5

15.1 Vertical disk movement

- Always switch off the machine before carrying out blade

adjustment.

the required height from the cutting table and tighten the clamping lever

starting to work.

15.2 Cutting

For safe use of the machine when cutting, push the carriage forwards

as the cut advances, placing your hands to the two sides of the carriage.

Never push directly on the piece to be cut.

- Check that the blade is aligned with the cutting line.

against the stop.

2. Start the engine.

3. Wait until the water reaches the blade.

4. Begin cutting.

5. Horizontal cutting movement is carried out by pulling the carriage

towards the blade.

- As cutting thickness increases, the blade is subjected

to greater stress. To avoid overloading the engine, the operator

should continually check blade feed speed. The speed will also

depend on the characteristics of the material being cut (hardness,

toughness etc.).

15.3.1 Cutting downwards from above

Position the piece to be cut. Start the sawing machine and start cutting

15.3.2 Changing the disk

For changing the disk, please refer to paragraph 4.

16. USING 650 DIAMETER CUTTING WHEEL

ration requires adjustment of the cutting head stroke, which is set by the

manufacturer for a 700 mm diameter disk. If not carried out properly, this

adjustment can damage the machine and cause hazard for persons, it

Proceed as follows:

1. Make sure that the machine is disconnected from the power supply.

2. Fit the 650 mm diameter disk according to the procedure described

in paragraph 14.

4. Lower the cutting head until the disk is in the best cutting position (the

disk outside diameter should protrude 15 mm from the cutting surface).

5. Turn the cam until locking the cutting head and tighten the bolt.

At this point, the cutting head is adjusted for a 650 mm diameter disk.

repeated restoring the original setting. If adjustment is not carried

out, the 700 mm disk would interfere with the piece holder carriage

structure and damage it with the risk of breakage.

- Note that the blade must have an external diameter of 650

mm, a central hole diameter of 25.4 mm and max. thickness of 4

mm.

17. MAINTENANCE

cians and only after the motor has been switched off.

- Always keep the guards in proper working order and free

from damage.Take particular care to ensure that the blade guards

- As there is the continuous risk of inadvertent damage to the

electric cables, these must be checked regularly each time before

the machine is used.

changing them when damaged.

Never leave the machine outdoors: it must be sheltered from the wea-

ther.

Below is a list of the cleaning operations that must be carried out at the

end of every shift.

17.1 Tank cleaning

Empty the tank by removing the drain plug. Remove cutting residue

using a jet of water.

Empty the drum opening the drum cap from right or left side.

17.3 Work surface cleaning

Always keep work surfaces clean. Residual dirt can impair cutting pre-

cision.

17.4 Guide rail cleaning

It is good practice to remove all traces of dirt from the guides.

17.5 Cleaning and maintenance of cooling circuit

If water does not reach the blade stop the machine immediately to avoid

blade damage.

If necessary, after disconnecting the machine from the power supply

17.6 Tensioning the drive belt

1. Switch off the electric motor and remove the plug from the power

supply.

2. Unscrew the 4 screws that secure the movable belt guard (ref.1,

blade support.

4. Tension the belt using the nut (ref.3): applying a force of about F=6

Kg to the centre of the free section of the belt, the arrow should be about

alignment of the motor pulley and the blade pulley

- To avoid shortening the life of the belt, the bearings and the

blade shaft, do not overtension the belt. Finally, check the two pul-

leys are aligned.

17.7 Changing the drive belt

1. Switch off the electric motor and disconnect the plug.

disk holder arm.

with the new one.

is correct, applying a force of approx. F=6 Kg at the centre of the free

of the motor pulley and that of the disk.

17.8 Repairs

- Before carrying out any maintenance operations, switch off

the machine, and remove the plug from the power socket.

- If the guards are removed to carry out repairs, they must be

Only use genuine IMER spare parts and do not modify them.

IMER U.S.A. Inc.

MASONRY 700

6

18. RESIDUAL RISKS AND SAFETY SIGNS

Although the sawing machine has been manufactured fully in complian-

ce with current regulations, residual risks exist that cannot be eliminated

and involve the use of appropriate individual protection devices. Ade-

the behaviour to be followed.

NOISE RISK

Ear protection must be worn

RISK OF INJURY TO THE HANDS

Safety gloves must be worn

RISK OF INJURY TO THE EYES

Eye protection must be worn

ABNORMAL USE RISK

Reading the manual before use is compulsory

Cutting with water is compulsory

RISK OF DRAGGING, ABRASION AND CUTTING

Do not remove the guards

Do not touch transmission components

Danger cutoff

RISK OF ELECTROCUTION

Danger electricity

Please be reminded that checking the use of IPDs is delegated to the

employer.

19. TROUBLESHOOTING

- CAUTION!!! All maintenance operations must be performed

exclusively with the machine switched off, with the selector set to

Fault

Cause

Remedy

Motor does not start

when switch is turned

Defective power cable

Check power

cables *

Plug not inserted in

socket correctly

Ensure correct

connection

Power cable from plug to

control panel detached

Remake the

connection *

Loose wire inside motor

circuit board

Remake the

connection *

A wire has become

disconnected inside the

panel

Remake the

connection *

Faulty main switch

Replace switch

A fuse has blown

Replace the fuse *

The overload safety

device has been

activated

Wait for a few

minutes and then

try restarting the

machine

Horizontal carriage

movement not

smooth

Guide rails dirty

Clean the guide rails

Lack of cooling water

supply to blade

Refer to section "cleaning and maintenance of

cooling circuit" (chapter 17.5)

Blade does not cut

Blade is worn

Fit new blade

Drive belt not tensioned

Tension the belt

Motor starts but

blade does not rotate

Belt is broken Replace drive belt

* Operation to be carried out by an electrician

IMER U.S.A. Inc.

MASONRY 700

7

FIG. 2 FIG. 4

FIG. 5 FIG. 7

FIG. 8 FIG. 9

IMER U.S.A. Inc.

MASONRY 700

8

IMER U.S.A. Inc.

MASONRY 700

9

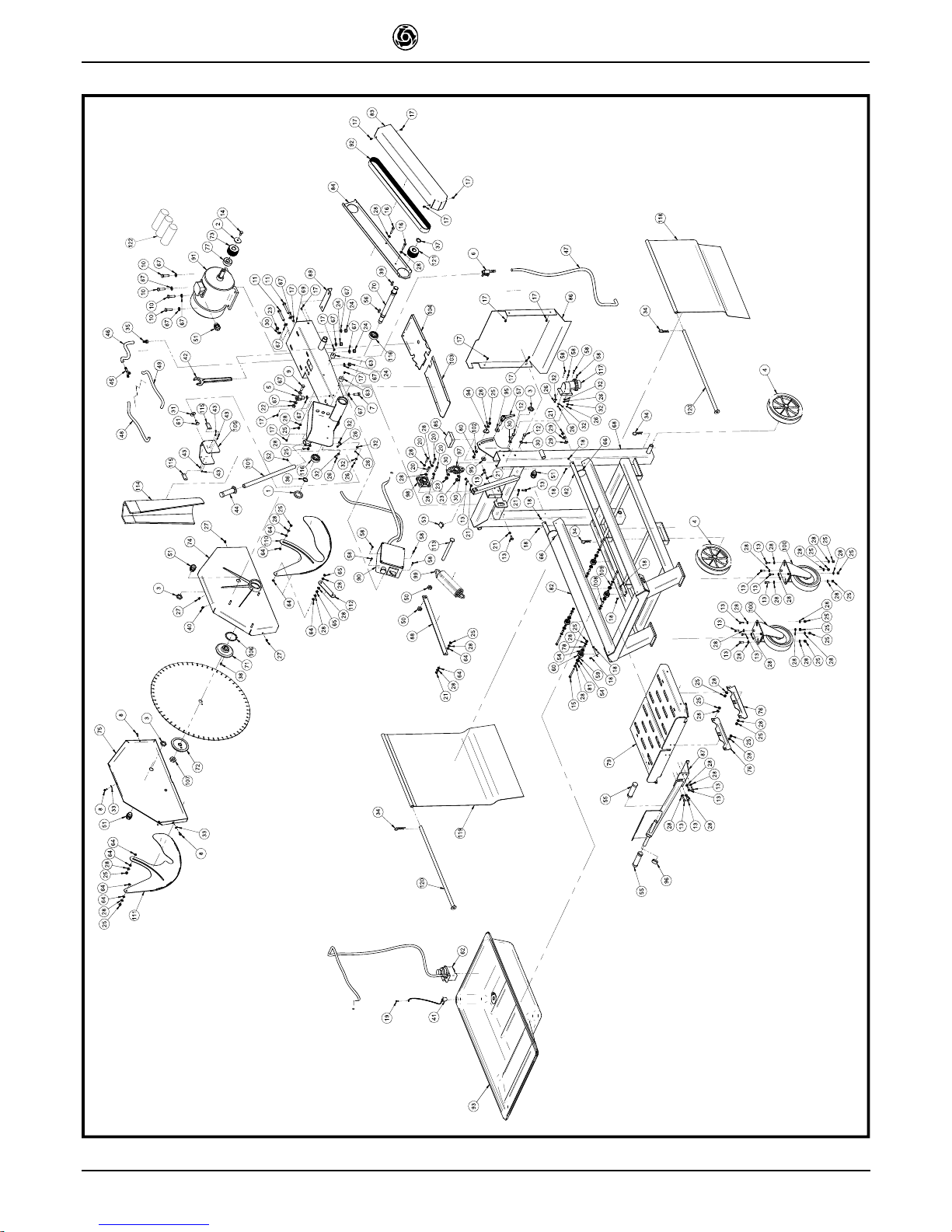

TAV.1 - MACHINE STRUCTURE

REF.

CODE

DESCRIPTION

NOTES

1

1207088

OIL SEAL RING

ADT D.45X62X8

2

1224113

WASHER

D.10X50X3 Z

3

1283984

NUT

PG 21

4

2211150

WHEEL

5

2213840

FORK

1676 M12X62 Z

6

2218075

VALVE

7

2222007

BOLT

TE 8.8 5739 M12X35 Z

8

2222021

BOLT

TEFR 8.8 5739 M6X16 Z

9

2222036

BOLT

TE 8.8 5739 M12X40 Z

10

2222050

BOLT

TE 8.8 5739 M12X45 Z

11

2222054

BOLT

TE 8.8 5739 M12X80 Z

12

2222073

BOLT

TE 8.8 5739 M10X35 Z

13

2222076

BOLT

TE 8.8 5739 M8X25 Z

14

2222077

BOLT

TE 8.8 5739 M10X20 Z

15

2222110

BOLT

TE 8.8 5737 M8X80 Z

16

2222176

BOLT

TE 8.8 5737 M8X50 Z

17

2222420

BOLT

AUT. TE 6950 D.4,8X13 Z

18

2222430

BOLT

AUTOF. TC 7971 4.8X9.5

19

2222449

BOLT

AUTOF. TC 6954 3.5X19

20

2222530

BOLT

TCEI 5931 M8X35 Z

21

2223570

NUT

5588 M8 Z

22

2223700

NUT

5588 M12 Z

23

2223920

SELF LOCKING NUT

AUTOBL. M10 7474

24

2223921

SELF LOCKING NUT

AUTOBL. M12 7474

25

2223923

SELF LOCKING NUT

AUTOBL. M8 7473

26

2223927

SELF LOCKING NUT

AUTOBL. M5

27

2224006

THREADED INSERT

28

2224140

WASHER

6593 D.8X18 Z

29

2224204

WASHER

6593 D.8X24 Z

30

2224340

WASHER

6592 D.10X21 Z

31

2224430

WASHER

6593 D.14X36 Z

32

2224528

WASHER

D.5X15 Z

33

2224531

WASHER

D.6X18 Z

34

2226700

SPLIT PIN

35

2226778

ELBOWN

F.3/8" D.10 RO150

36

2227240

OIL SEAL RING

7435 E/30

37

2227300

OIL SEAL RING

3653 E/28

38

2228738

PIN

1707 D.10X14

39

2229350

KEY

8X7X35

40

2230550

GREASER

1/8 DIRITTO SGS - 196

41

2235428

CONICAL CAP

42

2241574

KEY

43

2288810

RIVET

44

2288887

KNOB

45

2292355

Y DEVIATION

46

2292356

ANTI-FREEZE HOOSE

47

2292356

ANTI-FREEZE HOOSE

48

2292365

ANTI-FREEZE HOOSE

49

2292365

ANTI-FREEZE HOOSE

50

3201163

NUT

5589 M18

51

3201503

CABLE CLAMP

HSK-K PG21

52

3203921

BOLT

TC PH M5X10 N

53

3204420

CAP

54

3204945

BEARING

608 2RS1

55

3206079

KNOB

56

3206722

KEY

8X7X30

57

3206973

LEVER

58

3207152

BOLT

TCB 7687 M5X20

59

3207393

SPACER BRACKET

60

3207397

WHEEL

61

3208455

BOLT

TTDE M10X35 5732 Z

62

3208726

WATER PUMP

63

3210411

SPACER BRACKET

64

3210576

WASHER

D.8.4X17X1.5

65

3210623

SELF LOCKING NUT

M8 7474

66

3210646

CAP

67

3211038

WASHER

6592 D.13X24 Z

TAV.1 - MACHINE STRUCTURE

REF.

CODE

DESCRIPTION

NOTES

68

3224476

FRAME

69

3224479

CUTTING HEAD

GROUP

70

3224482

BLADE SHAFT

71

3224483

INNER FLANGE

72

3224484

OUTER FLANGE

73

3224486

3230340

PULLEY

THREE-PHASE

SINGLE-PHASE

74

3224510

DISC COVER

75

3224513

GUARD

76

3224514

PLATE

77

3224565

SPACER BRACKET

78

3224566

SPACER BRACKET

79

3234187

CARRIAGE

80

3224626

BOLT

TTCQ 5732-65 M8X25 Z

81

3224680

SPACER BRACKET

82

3224705

GUIDE BAR

83

3224740

GUARD

84

3224741

GUARD

85

3224814

CAP

86

3225043

PROTECTION

87

3225543

HANDGRIP

88

3225548

BLADE GUARD

ROTATION ROD

89

3225551

PLATE

90

3228124

3230332

JUNCTION BOX

THREE-PHASE

SINGLE-PHASE

91

3228123

3230330

MOTOR

THREE-PHASE

SINGLE-PHASE

92

3225564

BELT

93

3225642

DRUM

94

3225955

CAM

95

3225956

SPACER

96

3225984

PLUG

97

3225993

SUPPORT

98

3225994

SUPPORT

99

3225996

SPRING

100

3225997

WHEEL

101

3226001

HANDGRIP

102

3226002

WASHER

PS 13X19X1

103

3226003

FRONT HEAD

PROTECTION CASING

104

3226004

REAR HEAD

PROTECTION CASING

105

3226009

REAR SPLASHGUARD

SUPPORT

106

3226015

OIL SEAL RING

7435 E/75

107

3226028

NUT

5589 M24X2 SIN Z

108

3226034

SPACER BRACKET

109

3226035

SPACER BRACKET

110

3226036

CUTTING WHEEL RH

GUARD

111

3226037

CUTTING WHEEL LH

GUARD

112

3226039

TROLLEY CLAMPING

113

3226040

BOLT

TE 8.8 5737 M18X200 Z

114

3226043

REAR SPLASHGUARD

115

3226044

PLATE

116

2204220

BEARING

THREE-PHASE

117

3228125

3230465

PLUG

THREE-PHASE

SINGLE-PHASE

118

3228471

RH SPLASHGUARD

OPTIONAL

119

3228472

LH SPLASHGUARD

OPTIONAL

120

3228543

SIDE SPLASHGUARD

SUPPORT

OPTIONAL

121

3224486

3230342

PULLEY

THREE-PHASE

SINGLE-PHASE

122

3210448

CAPACITOR

IMER U.S.A. Inc.

MASONRY 700

10

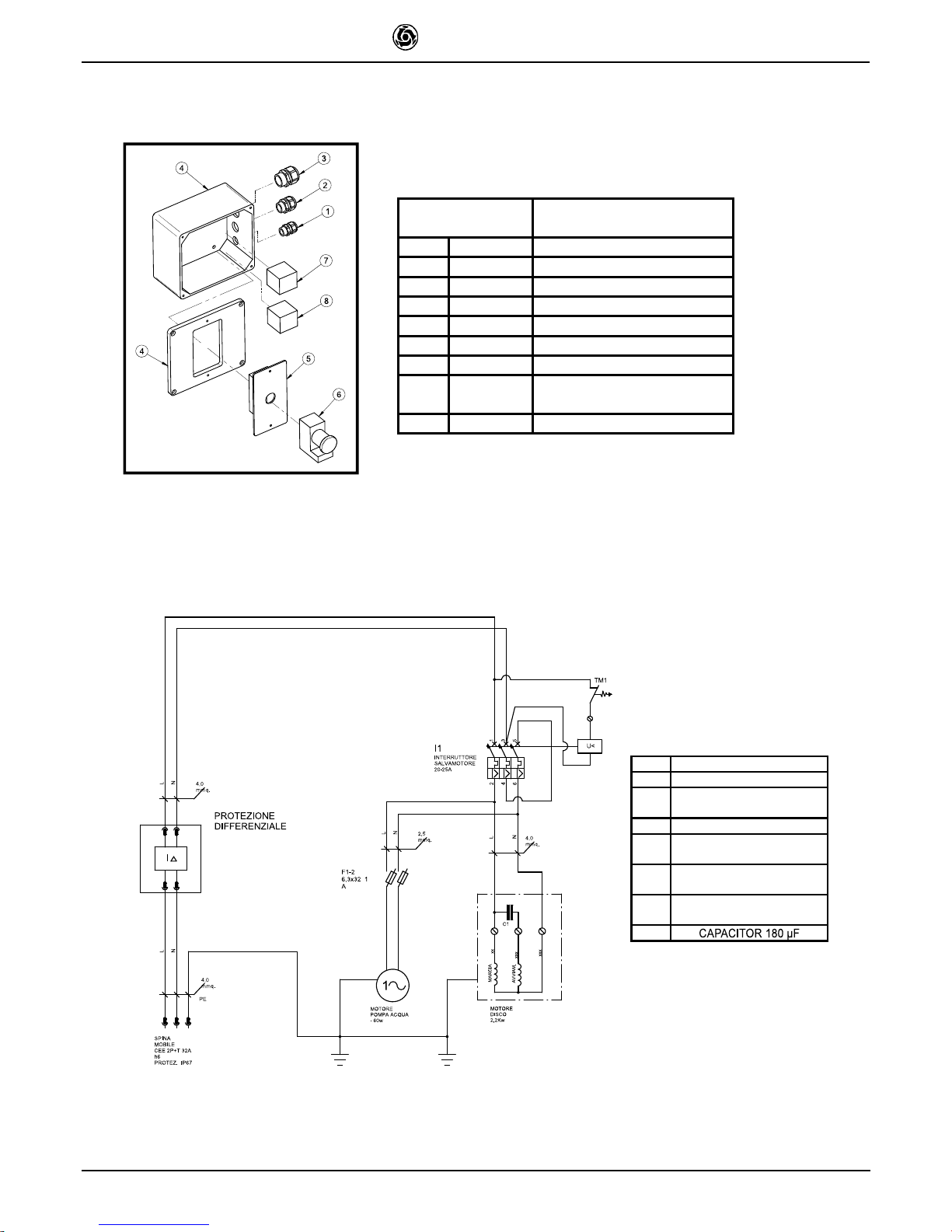

TAV.2 3228124 ELECTRIC PANEL THREE-PHASE

REF.

CODE

DESCRIPTION

1

3201217

CABLE CLAMP

2

3201442

CABLE CLAMP

3

3201503

CABLE CLAMP

4

3226296

JUNCTION BOX

5

3228375

SAFETY CATCH BUTTON

6

3226298

SWITCH

7

3228376

CONTACTOR

8

3228374

MAGNETOTHERMAL MOTOR OVERLOAD

PROTECTION CIRCUIT BREAKER

9

3228841

CONTROL CONTACTS

10

3228840

CONTROL RELAY

Table 4 MOBILE SOCKET

CODE

3230464

SINGLE-PHASE

CODE

3228456

THREE-PHASE

IMER U.S.A. Inc.

MASONRY 700

11

3230332

TAV.5 ELECTRIC PANEL

SINGLE PHASE

RIF.

COD.

1

3201217

CABLE CLAMP

2

3201442

CABLE CLAMP

3

3201503

CABLE CLAMP

4

3230333

ELECTRIC BOARD

5

3207929

SUPPORT

6

3207928

START AND STOP SWITCH

7

3207924

THERMO-MAGNETIC

CUTOUT SWITCH

8

3207922

COIL

RIF.

ID

CUTOUT SWITCH 30 mA

I1

THERMO MAGNETIC

CUTOUT SWITCH 20-25A

U <

MINIMUM VOLTAGE COIL

TM1

THERMAL PAD MAIN

ENGINE

F1

FUSEHOLDER 6,3x32 +

FUSE 1A

F2

FUSEHOLDER 6,3x32 +

FUSE 1A

C1

IMER U.S.A. Inc.

MASONRY 700

12

IMER U.S.A. Inc.

MASONRY 700

13

ONE YEAR WARRANTY

We warrant to the original purchaser that the IMER equipment described herein (the "equi-

pment") shall be free from defects in material and workmanship under normal use and

service for which it was intended for a period of one (1) year from the date of purchase by

the original purchaser.

Our obbligation under this warranty is expressely limited to replacing or repairing, free of

charge, F.O.B. our designated service facility, such part or parts of the equipment as our

inspection shall disclose to be defective. Parts such as engines, motors, pumps, valves,

electric motors, etc. furnished by us but not manifactured by us will carry only the warranty

of the manifacturer. Transportation charges or duties shall be borne by the purchaser. This

shall be the limit of our liability with respect to the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been damaged

by reason of accident, negligence, unreasonable use, faulty repairs, or which has not been

mantained and operated in accordance with our printed instructions for our equipment.

Further, this warranty is void if the equipment, or any of its components, is altered or modi-

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRES-

SED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OF

FITNESS FOR A PARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized to

make one on our behalf. We shall not be liable for any consequential damage of any kind,

including loss or damage resulting, directly or indirectly, from the use or loss of use of the

machine. Without limiting the generality of the foregoing, this exclusion from liability em-

braces the purchase's expenses for downtime, damages for which the purchaser may be

liable to other persons, damages to property, and injury or death of any persons.

This warranty shall not be deemed to cover maintenance parts, including but not limited

liability whatsoever.

IMER

U.S.A. Inc.

221 Westhampton Place

Capitol Heights, MD 20743

Ph. 301.336.3700

Fax 301.336.6687

Toll Free: 800.275.5463

www.imerusa.com

Table of contents

Other IMER Saw manuals