IMER MASONRY 350 Guide

ONE YEAR WARRANTY

Wewarrant tothe original purchaser thatthe IMER equipment described herein

(the "equipment")shall befreefromdefectsin material andworkmanship under

normaluseand serviceforwhich itwas intendedforaperiodofone(1) year

from

thedateofpurchase bytheoriginal purchaser.

Our

obbligation underthis

warranty is

expressely limitedtoreplacingorrepairing,

free ofcharge, F.O.B.our designated service facility, such partorparts of the

equipmentasourinspectionshalldisclosetobedefective. Partssuchasengines,

motors, pumps,valves, electric motors,etc.furnished byusbutnotmanifactured

byuswill carryonlythewarranty

ofthe manifacturer.Transportation charges or

duties shallbeborne

bythepurchaser.Thisshallbethe limit ofourliability with

respect tothequality

ofthe equipment.

Thiswarranty shall notapply

toanyequipment, orpartsthereof, whichhas been

damaged byreasonofaccident, negligence, unreasonableuse, faultyrepairs,or

which has not been mantained and operated in accordance with our printed

instructionsforourequipment. Further,thiswarranty

isvoidiftheequipment, or

anyofits components, isaltered ormodified in anyway.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSEDOR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITYOF FITNESSFORAPARTICULARPURPOSE.

Wemake nootherwarranty, representation

or

guarantee,noris

anyoneauthorized

tomake oneonourbehalf.Weshallnotbeliablefor

anyconsequentialdamageof

anykind, including loss or

damage resulting,directlyor

indirectly,fromthe useor

loss ofuseofthe machine. Withoutlimiting the generality oftheforegoing, this

exclusionfromliabilityembracesthepurchase'sexpenses

for

downtime,damages

forwhichthepurchaser maybeliabletoother

persons,damages toproperty,and

injuryordeath ofanypersons.

Thiswarranty shall notbedeemed tocover maintenance parts, including butnot

limitedtoblades, belts, hoses, hydraulic oil orfilters, forwhich weshallhave no

responsability orliabilitywhatsoever.

IMER U.S.A., Inc.

207 LawrenceAvenue

South San Fan

cisco,California94080

(650) 872-2200

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

IMER U.S.A. Inc.

MASONRY350

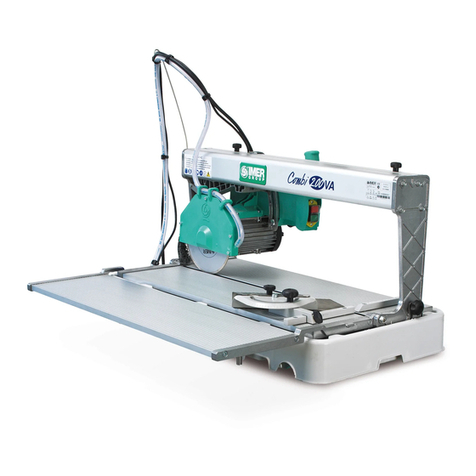

Fig. 1 MACHINELAY-OUT

1

2 TELESCOPICLEG

SPRAYGUARD

3 MOTOR

BLADESUPPORT

ARM

5 WATERPUMP

6 GUIDE

7 MAINSWITCH

8 WORKTABLE

9 WATERTANK

lQ BLADE GUARD

11 EARTHING SCREW

'2 HEADBLOCKAGE

DearCustomei

Congratulations on

your

choiceof

purchase:

IMERsawsarctheresultof

years

of

expenence andis

equipped

t'r4ThaiYelatesttechnalinnovations.

WORKINGINSAFETY

Toworkincomnletesafelv.readthefollowinainstructionscarefully.

-ThisOPERATION

AND

MAINTENANCEmanualmustbe

kept

onsite

by

the

person

incharge, e.g.theSITE

FOREMAN,

andmust

always

be

availableforconsultation.

-

Themanualistobeconsidered

integral part

ofthemachineandmust

be

kept

forfuturereference

(EN292/2)

untilthemachineis

disposed

of.

Ifthemanualis

damaged

or

lost,

a

replacementmaybe

requested from

thesawmanufacturer.

-Themanualcontains

important

information regarding

sitepreparation,

machine

use,maintenance

procedures, andrequests

for

spareparts.

Nevertheless,

theinstallerandthe

operator

mustbothhaveadequate

experience

andknowledge

ofthemachine

prior

touse.

-To

guaranteecompletesafety

oftheoperator, safe

operation

andlong

life of

equipment,

followtheinstructions

inthismanualcarefully, and

observeall

safety

standards

currentlyinforcefortheprevention

ofaccidents

atwork

(useofsafetyfootwearandgloves

in

acconiancewith3.1.N°3073

of

30/11/92).

times. Safetyglasses ora

protective

visormustbewornatall

MAKESURETHATSIGNSARELEGIBLE.

Itis

strictly

forbiddento

canyoutany

formofmodification

tothesteelstructureor

workingparts

ofthemachine.

-

IMERINTERNATIONALdeclinesall

responsibility

for

non-compliance

withlawsandstandards

governing

theuseofthis

equipment, in

particular;

improper

use,defective powersupply,lackof

maintenance, unauthorised

modifications,

and

partial

ortotalfailuretoobservetheinstrudionscontained

inthismanual.

1.DESIGNSTANDARDS

MASONRY350sawsare

designed

andmanufactured

according

tothe

following standards:I.E.C.

34.4;

EN

392(91/368CEE);

CEIEN60204.

2.NOISEEMISSIONLEVEL

Operatorexposure tosoundemissionlevels(continuous

sound

pressure

levels

equal

to"A"

weighting); theMASONRY350sawnoiseemission

level

duringcutting

is93

dB(A)

withcontinuous

rim

blade.

3.CUT11NGSPECIFICA17ONS

Thissawmodelhasbeen

speciallydesignedbyIMERforcutting

stone,

ceramics,marble, granite, concreteandsimilarmaterials. Onlywater-

2

cooleddiamondbladeswithcontinuousor

segmentededges

mustbe

used.Undernocircumstancesmust dry cuffingbladesbe used or

materialsotherthanthose

specified

above.IMERINTERNATIONAL

declinesall responsibility for

damagecaused

byimproper

useofthe

abovemachine.

TECHNICALDATA Masonry350

lade rpm rpm 2040/2150

lade diameter inc 14"

lade mounting

hole inc 1"

lotorrating Hp 1,5/3,0

lotorrpm rpm 3260I3450

;uttingtabledimensions inc 20 x 17"

)veralldimensions inc 43"x34"x47"

)veralldimensionsfor

ransport ft ,,

52 x30 x32

Veight lb 255

Veight

for

transport lb 300

lade rotation

irection(seen

from

lade clampingflange) ANTI -CLOCKWISE

urrent A 13,4111

Voltage V 1151230

requency Hz 60

4.CUT17NGCAPACITY

-max.cutting capacity

withverticalblade:5°

-max.cutting capacity

withbladeat45°:3"

-mm.dimensionsof

workpiece(width):

2'

-max. dimensionsof

workpiece(width):

20'

Vertical bladelowered:

wxhxl

mm(inc) =500(20")x25(1")x480(19')

=500(20")x60(3")x450(18")

=500(20")x120(5")x400(16")

Verticalbladeraised cutting

withbladelowered fromabove:

wxhxlmm(inc) =

500(20")x120(5")

x

450(16")

Bladeat45°:

wxhxlmm(inc) =

500(20")x

30(2")

x480

(19")

5.WARMNG

-Donotloadthesawwith

workpieces

thatexceedthe

specifiedweight

(max.

90

Ib)

-

Ensure

stability ofmachineand

workpiecebefore,duringorattercutting.

Installsupplementarysupportsurfaces atthesame heightasthe

worktable.

-Respect

the

environment;

usesuitable

receptacles

forcollectionof

Fig. I -Machine Lay-out

Payspecialattention to

warningsbearing the

following symboL

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

IMERsaws

comply

withEN

60204-1;

andarefittedwith:

-

protection

device

against

automaticre-startafter

powerfailure.

-

Short-circuit cutoutdevice

-

Motoroverloadcutoutswitch

IMER U.S.A. Inc.

MASONRY350

cooling

watercontaminated withcutting

dust.

6. SAFETYPRECAUTIONS

IMERsaws are designedforworkon construction sites and under

conditionsofnatural

light

andin

workshops

underconditionsofnatural

orartificiallightingofminimum500LUX.

Themachinemustneverbe usedinenvironments

subject

torisksof

explosionand/or undergroundsites.

-IMERsawsmayonly

beusedwhenfittedwithall

requiredsafetydevices

which mustbe in perfect

condition.

-Neverusemakeshift and/or faultypower

cables.

-Makeelectrical connections on theconstruction site wheretheywill

notbesubject

to

damage. Never stand thesawonpowersupply

cables.

-Laypowercableswherethey arenot

subjectto risk of

damageor

contactofconnectors withwater. Onlyuse connectors fittedwith water-

sprayprotection (lP55).

-Repairs to electrical installations mustonly

becarried outbyqualified

technicians. Always

ensurethatthemachine is disconnected fromthe

powersupply

andis

completely immobileduringrepairsandmaintenance

operations.

2

-Ensurethatthetankcontainssufficient

cooling

water.

3-Ensurethatthe

power

circuitcorresponds

tothe

requirements

as

indicated inSection11 "Electrical connections"

4-Connectthemachinetothe

powersupply

5-Settheswitchto"1"andwhenthemotorisstartedreturnto

position

"0"afterensuringthat

coolingwaterreachestheblade.

6-Check thatthedirection ofbladerotation corresponds tothat

indicated by

thearrowontheblade

guard.

7-Ifallisinorder,

proceed

withcutting.

12.EMERGENCYSTOP

-Intheeventof

emergency,stop

themachine

bypressing

the

stop

controlswitch.

Lts -

Themotorisfittedwithanoveiloadcutoutdevice.ffthe

motoroverheats,itwill

automatically

shutdown.Allowmotorto

coolbeforere-starting.

-Themotoris

protectedagainst

automaticre-startafter

intem,ptionsduetopowerfailure. Toresume

operation,

when

power

is

re-connected,

repeat

machinestart-upprocedure.

-Connectthemachinetoasuitable

equipotentialearthing

plant

ontheconstruction site with wirebraidofminimum 16

mm2f's

section.Theconnection

point

isidentified

bya

screwweldedtothe1

frame(see Fig.1),

andonthe

ratingplateby

the

earthingsymbol. 13.BLADEINSTALLATION(Ref.Fia.3)

-

Stop

thesaw

onlybymeans

ofthemainswitch.

The

symbolshownonthelabel

(seeleft)

indicatesthe

' Ianing

"ENSURE

ALLPROTECTIONDEVICES

ARE

INSTALLEDANDINPERFECTCONDITIONBEFORE

/ SWITCHINGONTHEMACHINE"

7.ELECTRICALSAFETY

8.TRANSPORTATION

(Ref.Fig2)

Lts WARNING!Always

removethe

plug

fromthe

powersocket

before

moving

the

saw,andlockhead

supportcaniage

movement

bymeans

oftherelativeknob

(ref.3).To

transport

themachineuse

slingingequipment with4ropelegs,fixing

thehookstotherelative

attachments

9.INSTALLATION(Ref.Fip.2)

Fixthehookstotherelative attachmentsonthemachineand liftthe

machineoutofitspackage.

-Unlockthelegsbysliding

out

splitpins(ref.2)

andpins(ref.1).

-Lockthe

legs

at

workingheight. Refitthe

pins

inthe

legsupports

and

insertthe

splitpins.

-

Installthemachineona

completely

evenandstablesurface.

10.ELECTRICALCONNECTION

By

meansofahexwrench

no.10,

removefrontscrews

(ref.1)

andloosen

theothertwoscrews

(ref.2)

whichsecuretheblade

guard.

Turnthe

guard

clockwiseto

gain

accesstothe

securing

screw

(ref.4).Useahexwrench

no.13toremovethescrew(tumanti-clockwise). Removethemobile

flange

andcheckthatthe

flanges, discshaftandbladearenot

damaged.

-

Neverusewornblades.

-Only

usebladesthatare

designed

forthenumberof

revolutionsindicatedon

the

machine

ratingplate.

-

Checkthatbladerotationconsponds

tothatindicated

ontheblade

guard.

Centretheblade

against

thefixed

flange,position

themobile

flange

and

tightenthesecuringscrewbymeans ofa hex wrenchno. 13(turn

clockwise).

Returnthe

guard

toits

originalposition

andlock

by

meansof

screws

(ref.1 and2).

-Ensurethattheblade

guardislocked

securely

into

position. -WARNING!An incorrectly

installed blade, orascrew

insufficientlytightenedcan

provokedamage

tothemachineor

injury

to

persons.

-Notethattheblademusthave anextemal diameterof

350mm., acentralholediameterof1"mmandmax. thickness of

3/25. -

Checkthatthebladetobeusedissuitableforthematerial

tobecut.

14.USE

Leavea

space

of5ftaroundthemachine to

operate

in

fufisafety.

-Donotallowotherpersons

to

approach

themachine

duringcutting.

-Neverusethemachinein fire-riskareas.Sparkscan causefireor

explosions.

-

Makesurethatthemachineisswitched offbeforepositioningor

handling.

-

Always

ensurethatthebladeisfreeof

any

contactbefore

start-up.

-Ensurecorrectinstallation ofall

protective

devices.

-Ensurethatbladerotation

correspondstotheindications

ontheblade

guard.

Beforestarting

work,

fillthewatertank.

Topup

during

operation whenever

necessary:N.B.thepumpsuction hosemust always

remain

immersed inwater.

Insertthe

plug

inthe

power

socket.

WARNING!

Forsafetypurposes theremoval ofprotective

guards

from

themachineis

strictlyprohibited.

Themachineis

protectedagainst

overload.

WARNING!Always

switchoffthemachinebeforecan

ying

outblade

adjustment.

14.1VERTICALBLADEMOVEMENT(RefFig.4)

Toraiseorlowerthe

blade,slackenknob

(ref.2)byturning

ftanti-clockwise.

Setblade

support(ref.1)tothe

required position

andlockbytightening

theknob

fully(ref.2).

Ensure thatthe

locking

knobistightenedfullybefore

Lts Ensurethatthereisanoverloadcutoutdevicefitted

up-

lineonthe

power

line.If

necessary,installan

IMERquickconnect

residualcurrentcircuitbreaker

(RCCB)(codeno.1169245available

inkitfoimfor

23oVmachines).

Ensurethat themains voltagecorresponds

tothat specified

forthe

machine:230V/6OHz -115V/6OHz.

L1\ All

powersupplyinstallations

must

comply

withCE!64-

8standards (ha,moniseddocumentCENELECHD384).

Theelectrical

power

cablemustbe

suitably

sedtoavoid

voltagedrops.

Cabledrums(with

collector

rings)

mustnotbeused.

Cabledimensionswill

varyaccording tothe

start-up

currentandlength

of

cable.In

general

cablesizesof4mm2aresufficientfor

lengthsup

to160

ft.Afterinstallationalwayscarry

out

voitagetesting

underload

conditions,

bothat

start-up

andduringoperation. During operation,voltagedrops

mustneverexceed5%.Inthecaseof

longer

cablesora

power

supply

network

subject

tovariations, usecableswith a sectionofatleast6

mm2.Cables usedonconstructionsites mustbe fittedwith suitable

external

sheathing

thatisresistantto

wear, crushing andextremeweather

conditions.

11.MACHINESTART-UP

Before

connecting themachinetothe

powersupply:

1-Ensurethatthemetalstructureisconnectedtoanearthing plantas

indicated inSection7

"Safety

Precautions".

3

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

starling wot*

14.2BLADEPOSITIONINGFOR45°CUTS(Ref.Fip.5)

Slackenknob (ref.1);

theblade

supportarm

(ref.2)isunlockedand

socanbesettoitslimit

position,i.e. inclinedat450with respectto

theworktable.Tightentheknobfullyto lock intoposition.

To

bnng

thebladebacktotheverticalposition(pos.O)carly

outtheabove

operations

inreverseorder.

Ensurethatthe

Iockingknob(ref1)

is

tightenedM!ybefore

starling

woi*.

14.3CU7TING

-Beforecutting, checkthatthe

bladeisalignedwith the

cutting

lineandthatthe

locking

knobsare tightenedfully.

Placethe

workpiece

ontheworktable

snuglyagainst

thefenceandstart

up

themotor.

Waituntilthewaterreachesthebladeandbegincutting.

Horizontal cuttingmovementiscaniedout

bypulling

the

caniage

towards

the

operatorby

meansoftherelative handle

(ref.1fig.6).

As

cuttingthicknessincreases,

thebladeis

subjected to

greaterstress.Toavoid

overloadingthe

motorthe

operator

should

continuallycheckbladefeed

speed.The

speedwillalsodependon

thecharactensticsofthematerialbeing

cut

(hardness,toughness

etc.).

14.3.1CUTSWITHBLADELOWEREDFROMABOVE

(RetF,g.8)

Bring

theblade

supportto its highestposition

andlock. Positionthe

workpiece

ontheworktable. Startthe

machine, unlocktheblade

support

andbegin

vertical

cutting

untilthebladereachesitslowest

point. Lock

the

support

oncemoreandproceed

withhorizontal

cutting.

14.3.1BLADECHANGE

To

changethebladerefertosection14.BLADEINSTALLATION.

A MAX 3/16

Donotuseblades forwoodorsegmenteddiskswith

slotswiderthan3/16.

15.MAINTENANCE

-WARNING! Always switchthe machine offand

removetheplugfromthe

power

socketbeforecarrying out

any

maintenance

operations.

-

Always

checkthatthe

protectiveguards

areinthe

correct

position

andin

perfect

condition.

-

Asthereisthecontinuousriskofinadvertentdamage

totheelectriccables,

thesemustbechecked

regularlyeach

timebeforethemachineisused.

-WARNING!If

theelectricmotororcontrol

panel

are

removedfor

maintenance, it's

necessary

to

replace

therelevant

sealsinorder

toguaranty

the

rightdegree

of

protection and

safetyagainstwater

penetration

insidetotheelectriccircuits.

Neverleavethemachineoutinthe

open.Makesurethatitisstored

inashelteredarea away

fromextremeweatherconditions.

Replaceworn or

faultycomponentswith originalspare parts.

15.1TANKCLEANINGONWORKCOMPLETION

On completion ofwork, emptythe tank and remove.Clean

thoroughlytoremovecuttingresidue.

15.2TANKREMOVAL (Ref.Fip.7)

Liftthetank (ref.1)todetach fromitssupports (ref.2)andremove

fromthesideindicated by

thearrow.

15.3WORKSURFACECLEANING

Alwayskeep worksurfaces clean. Residualdirtcanimpair cutting

precision.

15.4GUIDERAIL

CLEANING

Thehorizontal

guide

elementsonthe

carriage

areprotectedagainst

dirt

build-upbyscrapers.Howeverweadvise thoroughcleaningof

the

guide

railstoensure correct

operation.

WARNING! Donotuseanytype

oflubricantonthe

guide

rail.

15.5CLEANINGANDMAINTENANCE OFCOOLINGCIRCUIT

-

Ifwaterdoesnotreachthebladestopthemachineimmediately

to

avoidblade

damage.

-After switching offthemachine ensurethatthewaterlevel is

sufficient.

-Ifnecessary, after disconnecting the machine fromthe power

supply checkthatthe

tap,hoseand pumpfilterarenotblocked

-

If

necessary,

checkthatthe

impellerrotatesfreely(after

extended

periodsof

disuse)

-Ifnecessary,removethepump andcheckthatthe

pump/motor

coupling

isinperfect

condition.

15.6DRIVEBELTREPLACEMENT

-

Disconnectthemachinefromthepower

supply.

-

Removethewaterhoseconnection byloosening thehose

damp

onthe

bladeguard.

-

Removethe

blade,thetwo

flanges, theblade

half-guardsecuringscrews,

the

locking

knob(ref.1,

chart02)and removethebladeexternalhalf-

guard(motorside).

-

Removethebladeshaftwith

pulley

fromthe

bearing (ref.27,drawing 02)

andfitintothe

bearing

ofthe

half-guard previously

removed

(ref.14, chart

02).

-

Fitthenewbeltontothetwo pulleys

andrefitthebelttensioner.

-Refitthesealontheedgeofthe

guardand ensurethatitisingood

conditionandthatthetwolocatingpins

areinthecorrect

position.

-

Refitthe

guardinserting thebladeshaftintothe

bearing (ref.27, chart

02)taking

careto

align

thescrew

(ref.51,drawing02)

locatedontheslot

oftheheadfulcrum(ref.19,drawing02)

with the

lockinghandlehole

(ref.1,drawing02).

-Jointhetwobladehalf-guardsusing

thetwolocatingpins

to

aligncorrectly.

-

Screwinthetwoblade

half-guardsbytighteningdiagonallyopposite

screws

alternately.

-

Screwinandtighten

the

locking handlebefore

installing theblade.

16.TROUBLESHOOTING

N.B.:Beforecarrying

out

any

maintenance operations,

switchoffthe

machine,settheswitchto"O"andremovethe

plug

fromthe

powersocket.

FAULT CAUSE REMEDY

Motordoesnotstart

whenswitchis

turned

-

Defective power

cable

-

Plugnotinserted in

socket

correctly

-

Powercablefrom

plugtocontrol

panel

:ireinside

motorcircuitboard

-

Awirehasbecone

disconnected inside

the

panel

-

Faulty

mainswitch

-Theoverload

safety

devicehasbeen

activated

-Checkpower

cables

-Ensure correct

connection

-Connectcable- re

-Connectwire

-Remake the

connection

-Replaceswitch

-Waitforafewminutes

andthen

tiyrestarting

themachine

Verticalblade

movement not

smooth

-

locking

knobtoo

tight -Slacken knob

Lockingknobsdo

notlock -

threadisworn -Replaceknobs

Bladeinclination

notsmooth -

locking

knobtoo

tight -Slacken knob

Horizontalblade

movement not

smooth

-

locking

knobtoo

tight -Slacken knob

Lackof

cooling

water

supply

to

blade

Refertosection 16.6: "cleaning and

maintenance of

cooling

circuit'

Bladedoesnotcut

-

Incorrect blade

rotation

-

Bladeisworn

-Remove theblade

andrefitinthe

position

asindicated onthe

bladelabel.

-Fitnewblade

Motorstartsbut

bladedoesnot

rotate

Beltisbroken Replace drive

belt, see

Chapter 16.7

IMER U.S.A. Inc.

MASONRY350

4

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

IMER U.S.A. Inc.

'Y MASONRY350

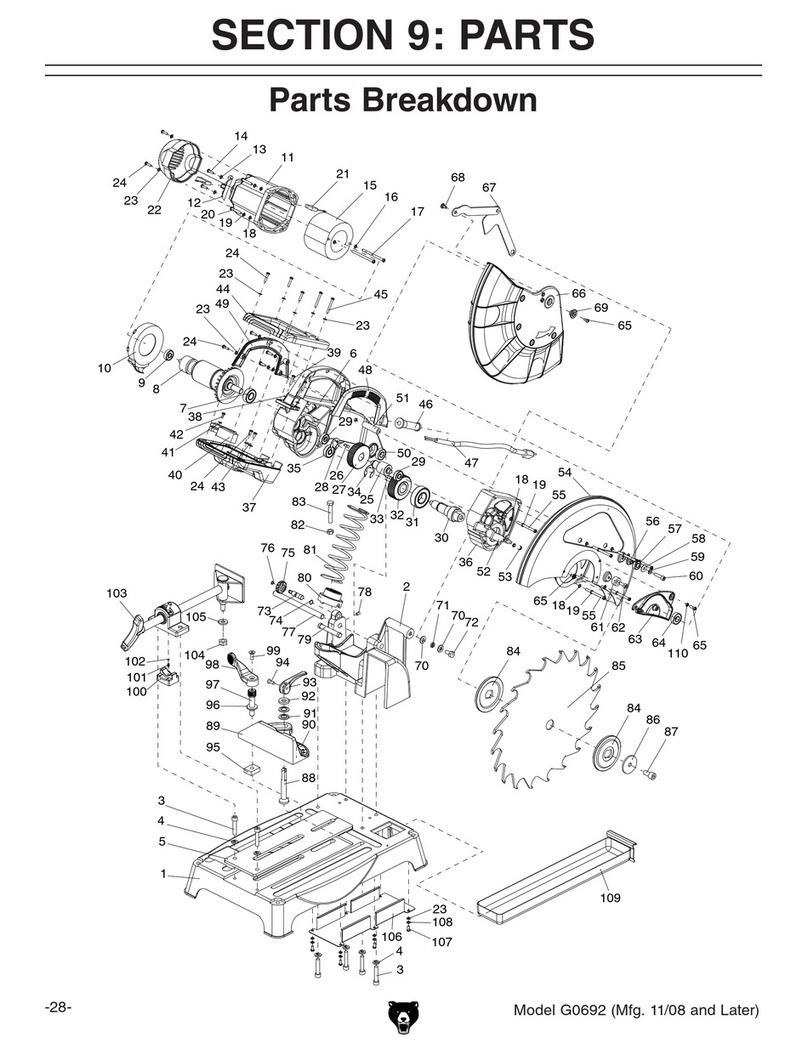

18. SPARE PARTS Allordersforspareparts must indicatethefollowing: 1 -Type

ofmechine.2 - Pertnumber endposition number ofeeoh pert.3 -Serial number end

yeer

ofmanufacture reported

onthe meohinesidenfificetion plate.

SYMBOL:

lntercheoeability(exemple):Poe..1 Rn. 3204530 weeinstelledon machinc,up toN5240endPos.1.1 Rn.3204520installedon machine W 5241 onwards. Pos. 1.1 is

interchangeable ( 9)with Poe. 1.Poe. 1endPoe. 1.1 arenot interchangeable ifthe(Jo symbol appears inthetable.

1 3208421 CARRIAGe

2 2222061 BOLT 5729 M 9x20

3 22225l5 BOLT 5931 M exie

4 3204040 BEARING Eee-2R51

5 2223923 SELFLOCKING NUT M.8

6 3207307 WHEEL

7 2222090 BOLT

e 32e57e2 ouioe BAR

9 3208442 LEFTFCN0CA0HEeIVE

Is 32ee441 1GBHETLF

ENCE AOHESIVE

II 3205581 RUBBER cOAITING

12 3206045 WASHER

13 3206086 PIN

14 3205475 COLLAPSIBLE LOG

lB 3200560 ROTARYBLADE ARM

16 3206096 SUPPORT

17 2223655 NUT 5509MIS

18 3201015 PLUG

19 2222567 SCROW

20 3200609 SPRAYGUARD

21 3200541 FRAME

22 3205526 WATER RUN-OFF TRAY

23 2222425 SCREW AUTOFOR.TE 4,2X13

6

29 2235428 PLUG

26 3206030

3206269 WATER PUMP IISVI6OHz

230VI65Hz

27 2292365 TUBE

29 3205704 BOLT 5737 MISXIOO

29 2223650 NUT 5588MIS

35 3206104 HEAD CLAMP

31 2222146 SCREW 5739MISx30

32 2222120 SCREW 5737MleXeO

33 3200414 LEVER

34 3208429 GONIOMETER

35 3207213 GUIDE BAR SUPPORT

36 3200420 TROLLEYSLIDE

37 2224531 WASHER 8593 OslO

38 2223500 NET 5588 M4

39 3206103 LOCK PLATE

40 3209333 KNOB MO

41 3208429 TROLLEY

CLAM

FWG

42 2222016 SCREW 5739 M8x29

43 2223924 NUT 5088 M6

44 3209332 CAM

45 2222010 SCREW 5931 M5X35

46 2223923 NET MO

1 3204530 Riduttore Reducteur Reducer Untersetzungsgetriebe Reductor 5240

2 3204520 Riduttore Réducteur Reducer Untersetzungsgetriebe Reductor 5241

AKOI4 TAB.2 FRAME ASSEMBLY

RIF. COD. USA DETAILS RIF. COD. USA DETAILS

24 3204818 DRUM

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

AK014 TAB.2MOBILEHEADASSEMBLY *IMER U.S.A. Inc.

MASONRY350

TAB.2

RIF. COD. USA DETAILS

1 2284827 SNOLE

1. 222438 ASI-IER 6593012X25

3 222254 OLT 5931M6X30

4 222304 UT M105721-6S

S 323276 OVER

6 321419 OLT 5737 M1OX5O

.1. 321465 EARING 6000 2R5

6 320391 OLLER 6592 010X20

9 321419 ASHER

10 321419 ELTTENSIONERARM

11 222214 OLT 5737M10X65

12 222392 UT AUT M10 7474

13 321420 PRING

14 320651 EARING 6203 2RS

15 320473 ELT

16 320473 ULLEY

17 320673 LADESHAFT-PULLEY

18 222201 DLT 5739 M6X20

19 323274 EADFULCRUM COUBI

19 320649 EADFULCRUM MASONRY350

20 2204510 EARING 6009 2R5

21 2228820 PN 6x14

22 3204788 PN

23 3204787 PRING

24 3207366 OMPENSATING RING

27 2204540 EARING 6205 2RS

28 3232759 LSEALRING 35X52X7

31 3209687 OLT 5737

U

6X135

32 2224531 ASHER 65930 6X15

33 2223924 NUT AUTOBL.M6

34 3209400 SPRAYGUARD

30 3205635 VALVE

36 3209387 TUBE

37 2222709 BOLT 5739M5X10

38 320938 SUPPORT

41 228482 HANDLE COMBI600-MASONRY

42 222251 BOLT 5931 V8X16

43 3204777 NNERFLANGE

45 320477 OUTERFLANGE

46 22241

47 222201

SASHER

3OLT 65930 8X18

5739 V9X20

49 320940 BLADE COVER

49 2222021 BOLT 5739M6X16

50 320712 LABEL

51 3203914 BOLT TTOM12X90

52 323274 GASKET

53 3206131 WASHER 3545016x35x1,4

54 320940 SUPPORT

55 RIVET

56 SHOCKABSORBER

57 WASHER 659305x15

50 BOLT M6X1OZ

59 WASHER 659206X12.5

12

2j3

II Ei

J)

AKOI4 TAB. 3 ASSEMBLYOFMOTOR

RIR COD. USA DETAILS

1 3214262

22856G1 CAPACITOR 11SV/60F-IZ

23GV/6GHZ

2 3207920 CONTACTOR

3 3207927

3207924 COIL I1SV/00H7

23GV/SGHZ

4 3201503 CABLE-CLAMP

S 3207933 COVER

6 3232743 GASKET

7 3250412 BOLT

8 3207934

3207937 MOTOR 115V/601t

230V/6OHz

9 3205924 LABEL

10 3207929 JUNCTIONBOX

11 3207929 PUSH

12 3232270 GASKET

13 1222252 BOLT

14 3201217 CABLE-CLAMP

15 3207184

3208070 PLUG 11SV/6OHz

230V/6OHz

16 3206171 SWITCHCOVER

17 3206170 WATERPUMPSWITCH

6

7

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

AKOI4 TAB. 4.1 ASSEMBLYOFMOTOR *IMER U.S.A. Inc.

MASONRY350

10 8

15 2Assembly

ofmotor

L428 (TAB.4.1)

19

16

RIF. COD. USA DETAILS

1 3203680

3204830 MOTORFLANGE 115V/6OHz

230V/6OHz

2 2222970

2222911 SOLT 115V/6OHz

230V/6OHz

3 2223352

2223280 NUT 115V/6OHz

230V/6OHz

4 3213619

3216622 CASINOANDSTATOR 115V/6OHz

230V/6OHz

5 3214262

2285601 CAPACITOR 115160 MF8OV250

230/50 MF35V450

6 2281955 TERMINALS 115160 230/60

7 2227900

2237340 SPLIT RING 115V/6OHz

230V/6OHz

8 2204390

2204391 BEARING 115V/6OHz:62042Z

230V/6OHz:62052Z

9 2229325 KEY 6X6X256604

10 3203681

3204829 ROTOR 115V/6OHz

230V/6OHZ

11 2291495

2291494 COVER 115V/6OHz

230V/6OHZ

12 2227097

3214031 OILSEALRING 115V/6OHz

230V/6OHZ

13 2291453

2291454 MOTORFAN 115V/6OHz

230V/6OHZ

14 2291281

2291282 FANCOVER 1ISV/6OHz

230V/6OHZ

15 2216321 GASKET

16 3213032 COVER

17 3204411 CABLECLAMP 1P68PG16

18 3214028 SEALRING 018,8X1.8(P016)

19 2222465 SCREW TRILOB.M5X15

20 3203262

3203980 RATINGPLATE 115V/6OHz

230V/6OHz

21 2288792 RIVET

22 3203678 MOTORFLANGE 115V/6OhZ

Ru. Cod.

TAB.1-

WHEEL KIT

2226700

2

GB

SPLIT PIN

2211150

3 WHEEL

3206261

DETAILS

4 3206262 LEFTTUBE GUIDE

5 2222082

6

RIGHTTUBE GUIDE

SCREW

2223650

7 DISK

3206641

8 WASHER

5739

M

10X60

3206260

5588M10

WHEELTUBE 659228X5OX2

WheelKit(TAB. 1)

Fig.19 USA

LI PHASELINECONDUCTOR

N NEUTRALLINECONDUCTOR

PE PROTECTION CONDUCTOR

II THERMO-MAGNETIC CUTOUT DEVICE

Cl MOTOR CAPACITOR

KI OOIL

MI BLADE MOTOR

M2 PUMP MOTOR

12 SWITCH

II

12 Cl

I

PE

rTl

-Jr

A

L r

I— j

Fig. 19-Wiring Diagram

8

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Other manuals for MASONRY 350

2

Table of contents

Other IMER Saw manuals

IMER

IMER COMBl 250/1000 VA Guide

IMER

IMER COMBI 250 VA Guide

IMER

IMER C 350 i-Power Guide

IMER

IMER MASONRY 750 PLUS Guide

IMER

IMER COMBI 250/1000 VA Guide

IMER

IMER EASY 180 Guide

IMER

IMER COMBI 200 VA User manual

IMER

IMER Combi 200 Installation and operation manual

IMER

IMER MASONRY 500 Datasheet

IMER

IMER MASONRY 700 Guide