-18-

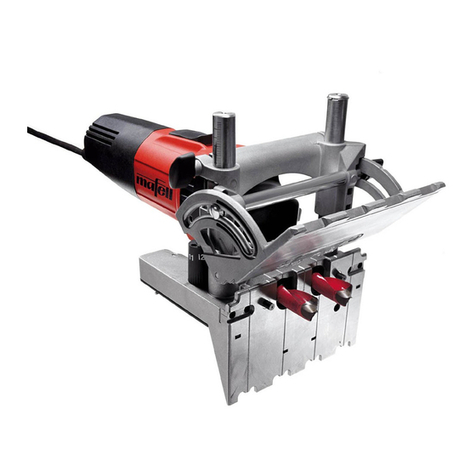

Turn the tool holding fixture 2 (Fig. 2) such that

the screws 3 are on top.

Unfasten the screws with the Allen key.

Pull off the drill bits 4 to the front.

Push the new drill bits into the tool holding

fixture up to the limit stop. Align the plain

surface of the drill bits with the screw holes.

Tighten the screws against the plain surfaces.

Check the drill bits' seat.

After the tool change, you have to

readjust the zero setting for the drill

depth.

Unfasten the wing nut 11 (Fig. 3)

Completely swing open the tilting stop 9.

Tighten the wing nut 11.

Place the machine with the swung open limit

stop onto a flat surface.

Push the motor casing 5 forward until the tip of

the drill bears on this surface.

Unfasten the wing screw 6.

Push the depth stop 7 up to the limit stop to the

top and tighten the wing screw.

Push the indicator 8 to zero.

4.5 Pivot adjustment

The tilting stop 9 (Fig. 3) can be

continuously adjusted in the range

from 0° to 90°. Three latching

positions facilitate a fast setting of

the angles 22.5°, 45° and 67.5°.

Unfasten the wing screw 11.

Tilt the tilting stop to the desired angle.

Retighten the wing nut.

4.6 Drill depth adjustment

The drill depth can be continuously

adjusted in a range between 0 - 37

mm (0 - 1 7/16in.) on the DD40G or

0 - 40 mm (0 - 1 9/16 in.) on the

DD40P.

Unfasten the wing nut 6 (Fig. 3)

Push the depth stop 7 to the desired value.

Retighten the wing nut.

4.7 Adjusting the drilling clearance

The edge clerance is continuously

variable between 7 and 40 mm

(9/32 and 1 9/16 in.).

Unfasten the wing nut 16 (Fig. 4)

Push the tilting stop 9 (Fig. 3) to the desired

scale value.

Retighten the wing nut.

With the rotating revolver limit stop 17 you can select

five firmly preset edge clearances:

6.5 mm, 8 mm, 9.5 mm, 11 mm, 12.5 mm (1/4 in.,

5/16 in., 3/8 in., 7/16 in., 1/2 in.)

5 Operation

5.1 Initial operation

Personnel entrusted to work with the machine must

be made aware of the operating instructions, calling

particular attention to the chapter "Safety

instructions".

5.2 Switching on and off

Switching on: Push the switch 23 (Fig. 5)

forward until it engages.

Switching off: Push onto the rear end of the

switch. The switch jumps into off position.

5.3 Drilling according to tracing

The tilting stop 9 (Fig. 3) has three reference

markings. The reference markings on the left and

right each correspond to the centre of the drill.

Clamp the workpiece or prevent it from moving

by using the anti-slip mats supplied.

Position the machine on the workpiece and align

the machine by means of the reference

markings.

With your free hand, press the tilting stop

against the workpiece.