MSA CONTENTS

AirMaXX classic 3

Contents

1. Safety Regulations ..................................................................................................5

1.1. Correct Use.....................................................................................................5

1.2. Liability Information .........................................................................................5

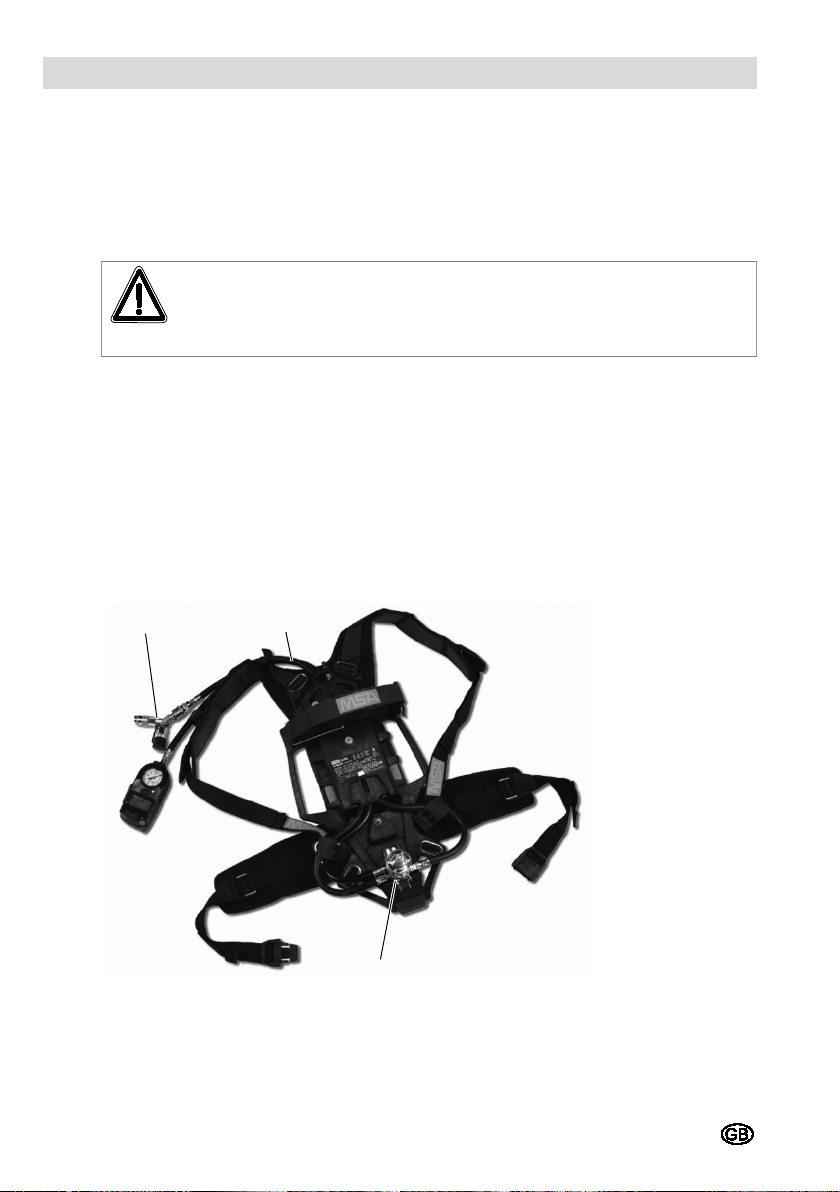

2. Description...............................................................................................................6

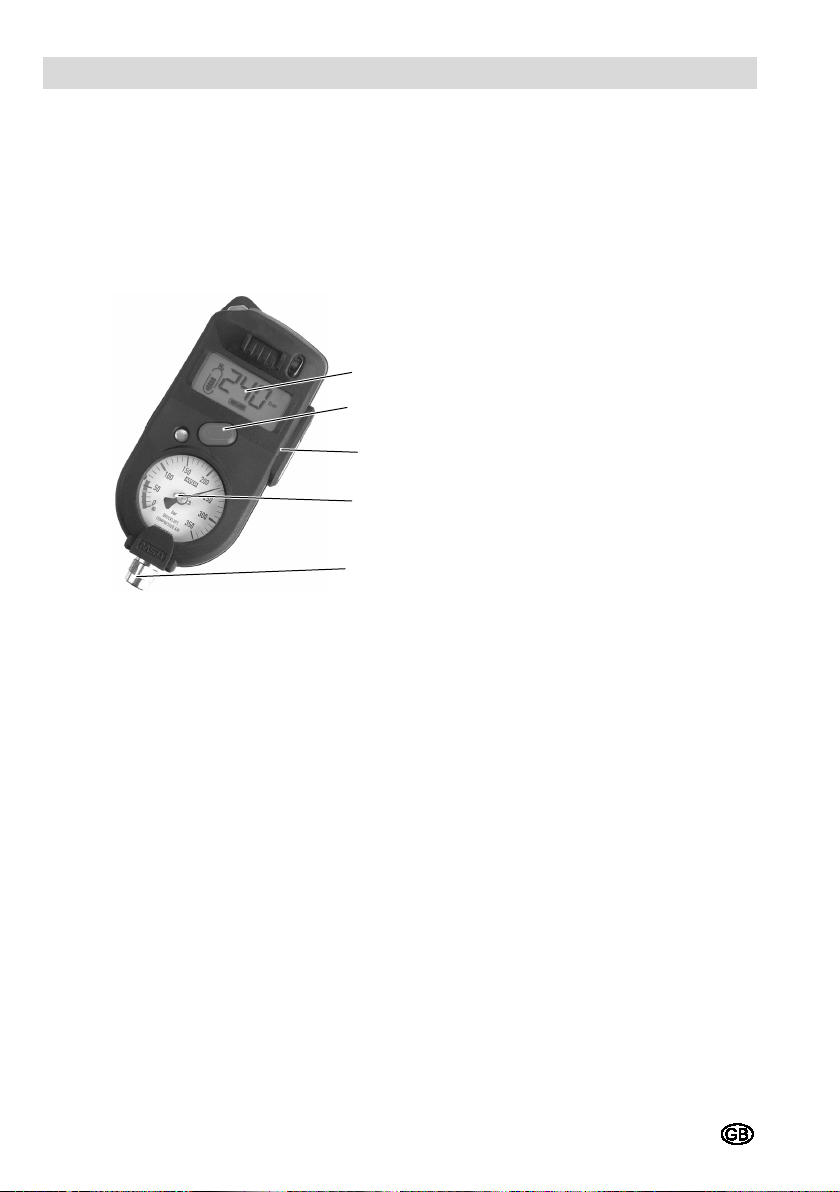

2.1. Standard Model (AirMaXX classic) .................................................................7

2.2. Model AirMaXX classic S ................................................................................9

2.3. Model AirMaXX classic Z .............................................................................. 10

2.4. Model AirMaXX classic-CLICK......................................................................11

2.4.1. alphaCLICK 2 Coupling 300 bar ......................................................12

2.4.2. alphaCLICK 2 Cylinder Adaptor 300 bar.......................................... 12

2.5. Model AirMaXX eXXtreme classic ................................................................13

2.6. AirMaXX classic Combinations .....................................................................13

2.7. Technical Data ..............................................................................................14

3. Using the Compressed Air Breathing Apparatus ...............................................15

3.1. Prior to the First Use ..................................................................................... 15

3.2. Connecting One Compressed Air Cylinder ...................................................15

3.2.1. Pressure Reducer with Thread Connection .....................................16

3.2.1.1. Preparing the Apparatus for Use with One Compressed Air

Cylinder.........................................................................................16

3.2.1.2. Connecting One Compressed Air Cylinder ...................................16

3.2.2. Pressure Reducer with alphaCLICK 2 .............................................18

3.2.2.1. Installing Quick Connect Adaptor to Cylinder................................18

3.2.2.2. Connecting One Compressed Air Cylinder ...................................19

3.3. Connecting Two Compressed Air Cylinders..................................................20

3.3.1. Pressure Reducer with Thread Connection .....................................20

3.3.1.1. Preparing the Apparatus for Use with Two Compressed Air

Cylinders.......................................................................................20

3.3.1.2. Connecting Two Compressed Air Cylinders..................................20

3.3.2. Pressure Reducer with alphaCLICK 2 .............................................21

3.4. Adjusting the Back Plate ...............................................................................22

3.5. Condensed Check Prior to Use.....................................................................22

3.6. Donning the Compressed Air Breathing Apparatus ...................................... 22

3.7. Donning the Full-Face Mask .........................................................................23

3.8. During Use ....................................................................................................23

3.9. Using the Second Connection.......................................................................23

3.10. Removing the Compressed Air Breathing Apparatus....................................24

3.11. Removing the Compressed Air Cylinders .....................................................24

3.11.1. Pressure Reducer with Thread Connection ..................................... 24

3.11.2. Pressure Reducer with alphaCLICK 2 .............................................25