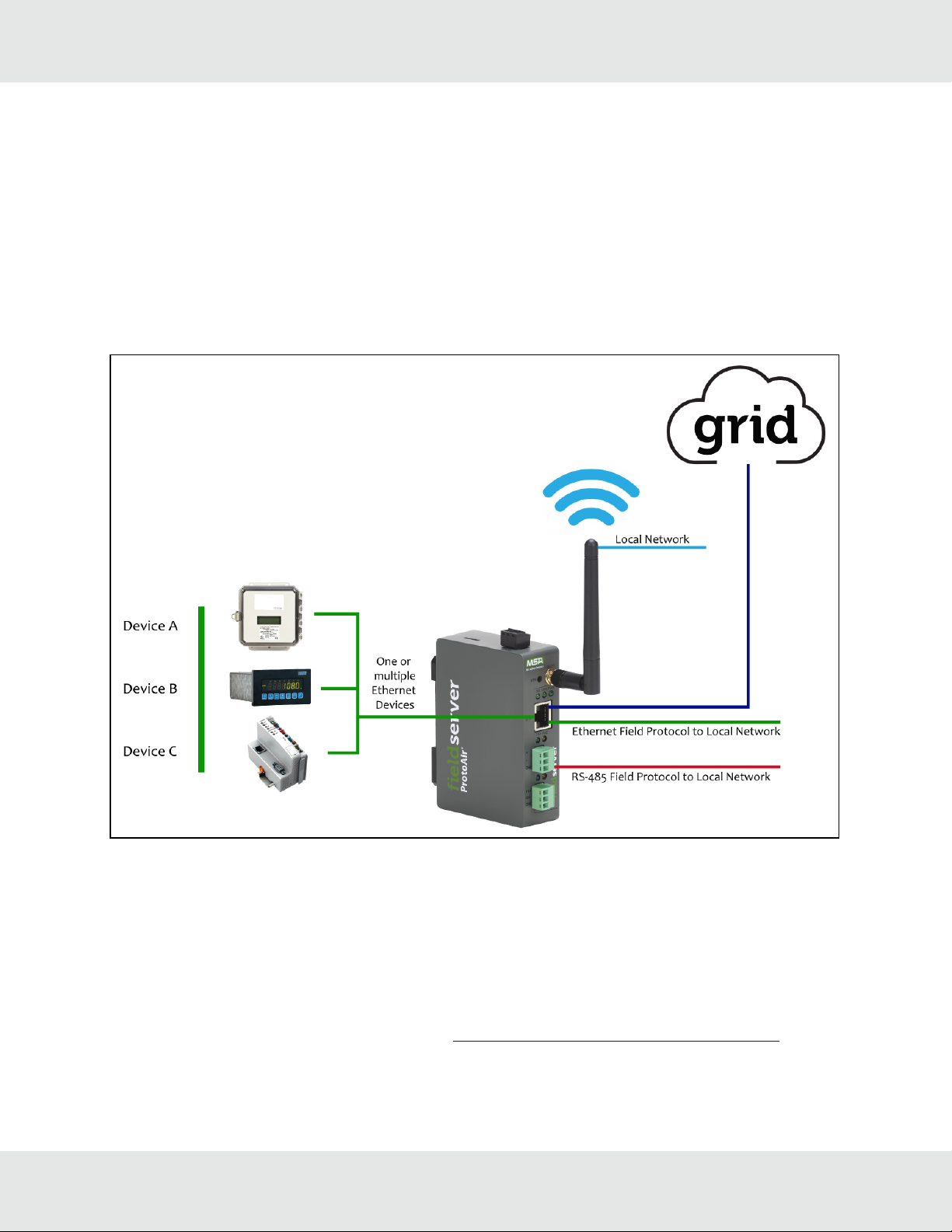

MSA ProtoAir FPA-W44 User manual

Other MSA Safety Equipment manuals

MSA

MSA SavOx User manual

MSA

MSA PremAire System User manual

MSA

MSA AUER 3S-Basis Plus User manual

MSA

MSA BD mini User manual

MSA

MSA Workman SRL-R User manual

MSA

MSA Advantage 4000 Series Setup guide

MSA

MSA General Monitors FL4000H User manual

MSA

MSA OptimAir Mask-Mounted PAPR User manual

MSA

MSA Kwik Draw User manual

MSA

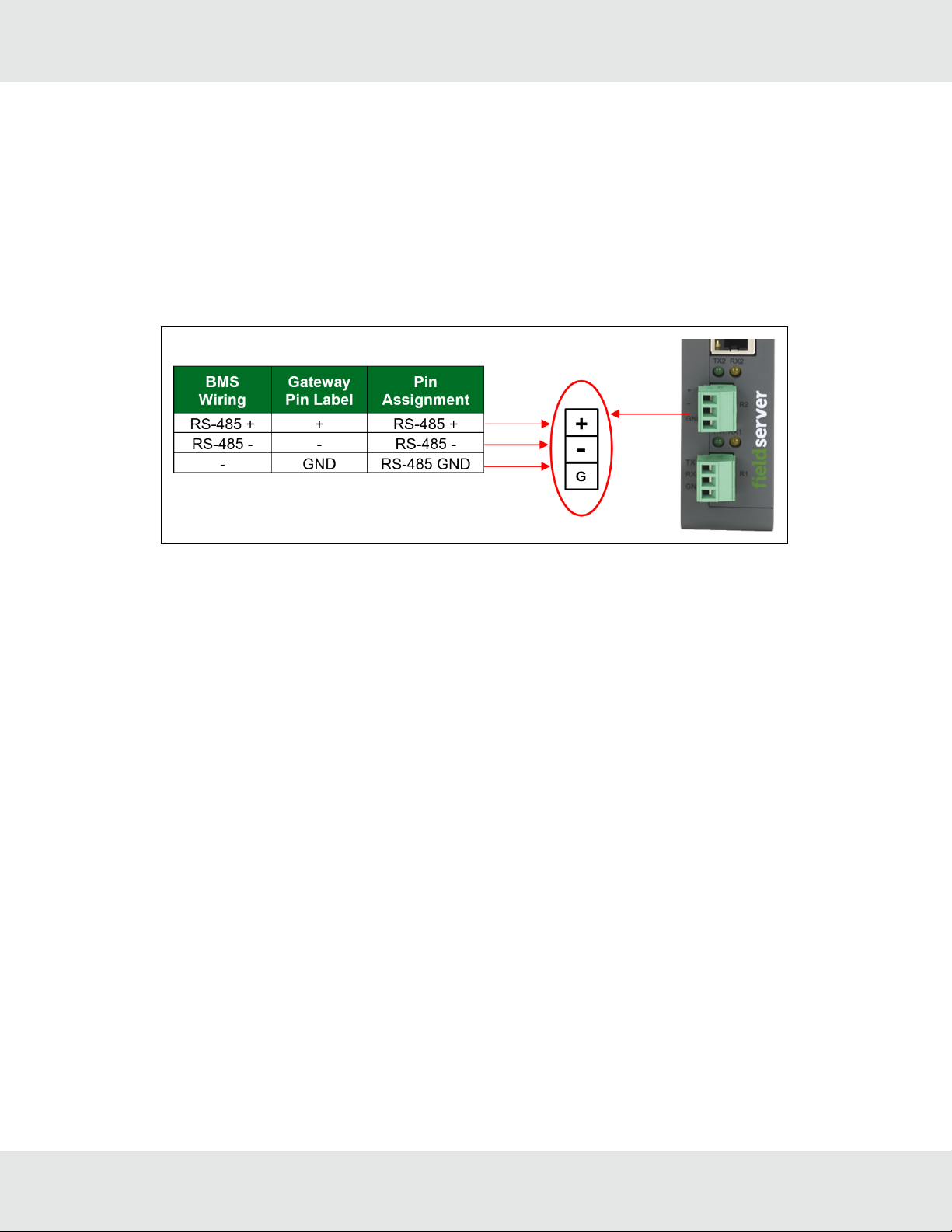

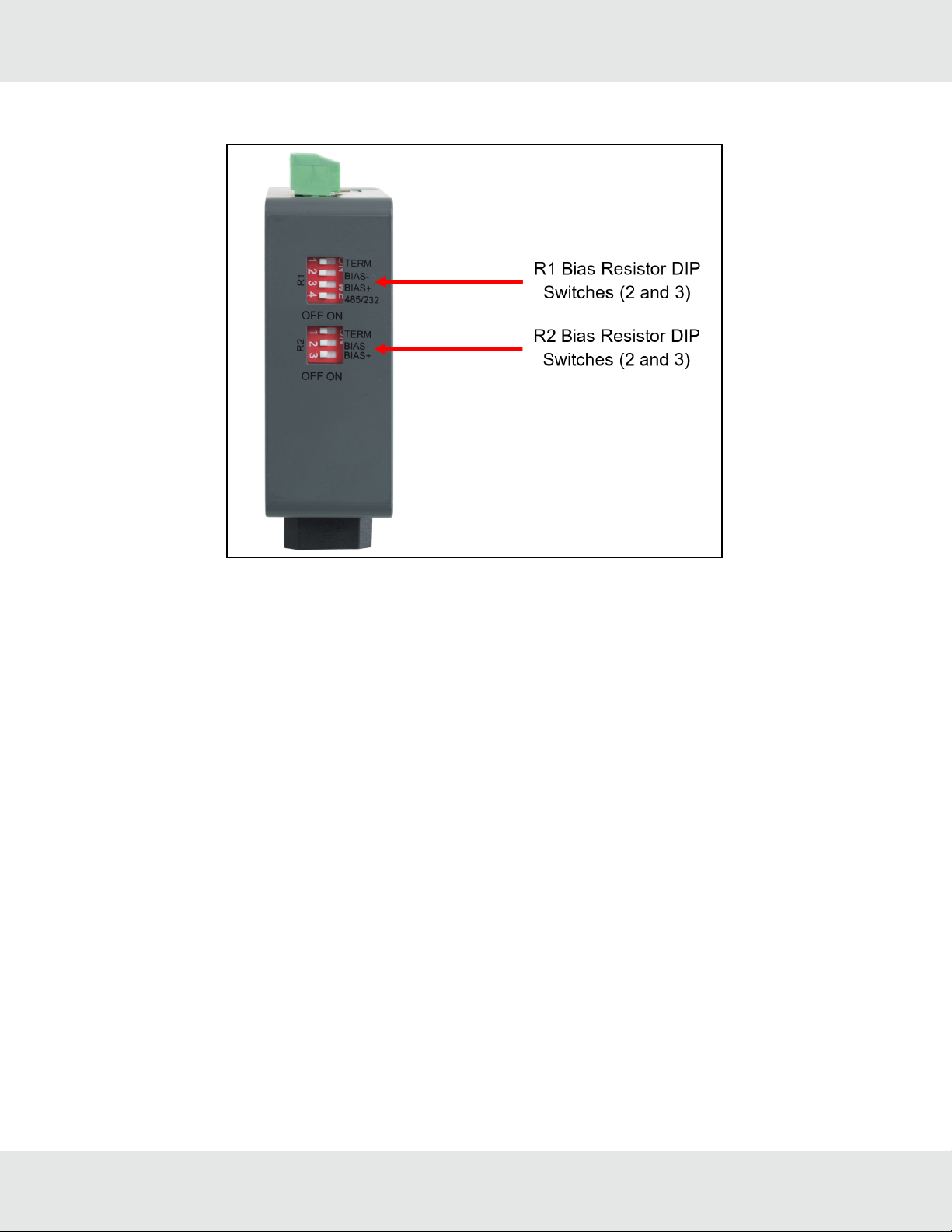

MSA fieldserver ProtoNode FPC-N54 User guide

MSA

MSA Dyna-Lock 506208 User manual

MSA

MSA PremAire Cadet Escape Respirator Setup guide

MSA

MSA Latchways SRL User manual

MSA

MSA ULTIMA X5000 User guide

MSA

MSA PremAire System User manual

MSA

MSA PremAire System User manual

MSA

MSA 10207284 User manual

MSA

MSA FieldServer FS-QS-1 Series User guide

MSA

MSA HUB User manual

MSA

MSA V-GARD 900 Series User manual

Popular Safety Equipment manuals by other brands

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual