1

ORIG0017-1

4127388M/C

31/05/2007

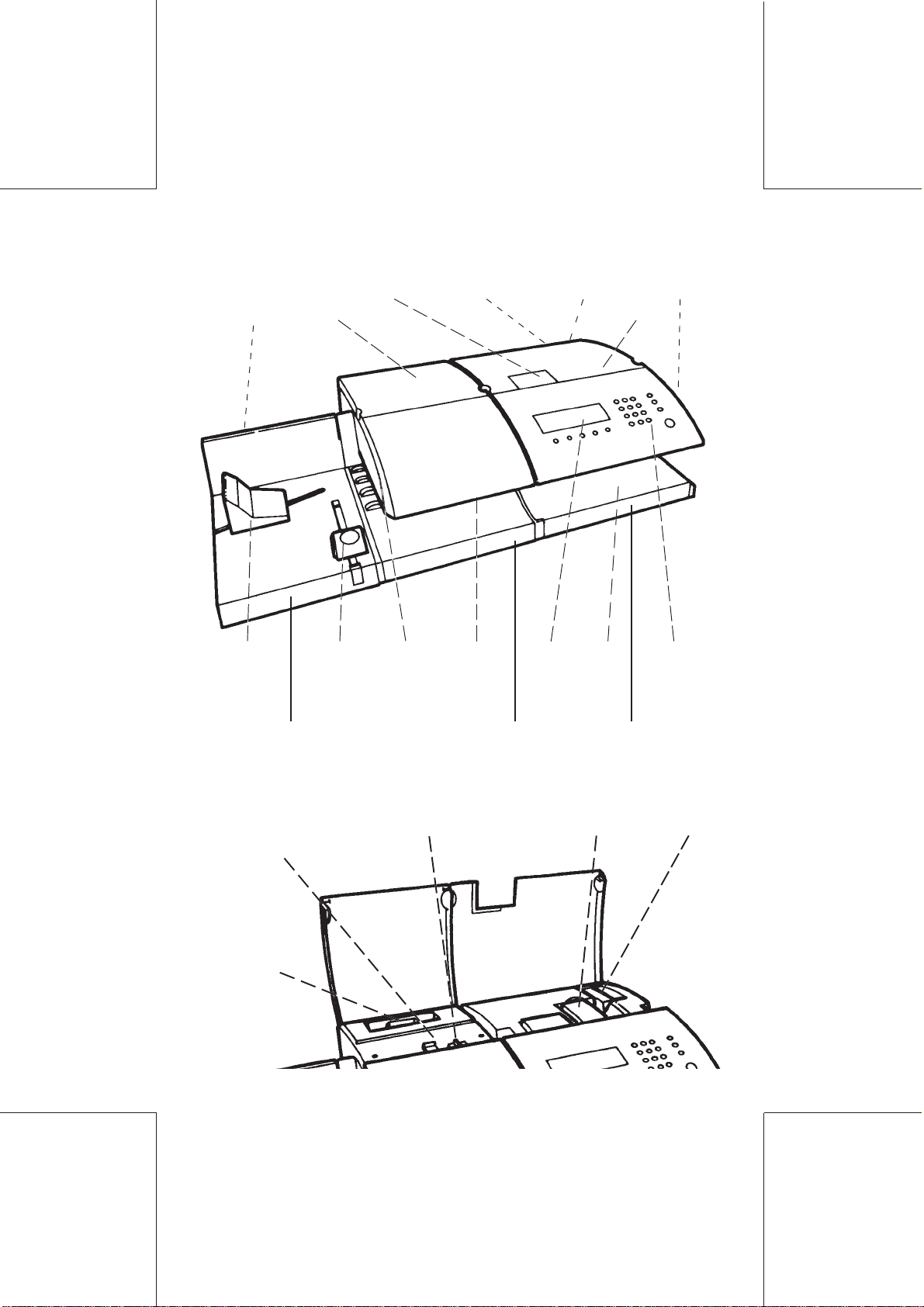

INTRODUCTION

CongratulationsonchoosingtheNeopostIJ70frankingsystem.

TheIJ70istheresultoftheexpertiseandinnovativecapabilities

ofaworldwideNeopostgroupand,usinginkjettechnology,itwill

integrate into your working environment to enhance your mail

processingoperation.

The IJ 70 has many capabilities that will be important to your

business:

As well as being productive (upto 9,000 items per hour for

machine only, and up to 5,100 items per hour in dynamic scale

mode),theIJ70isdesignedtobeauserfriendlymachinethat

can fit into any working environment with its innovative and

attractivedesign,simpleusersettingsandverylownoiselevel.

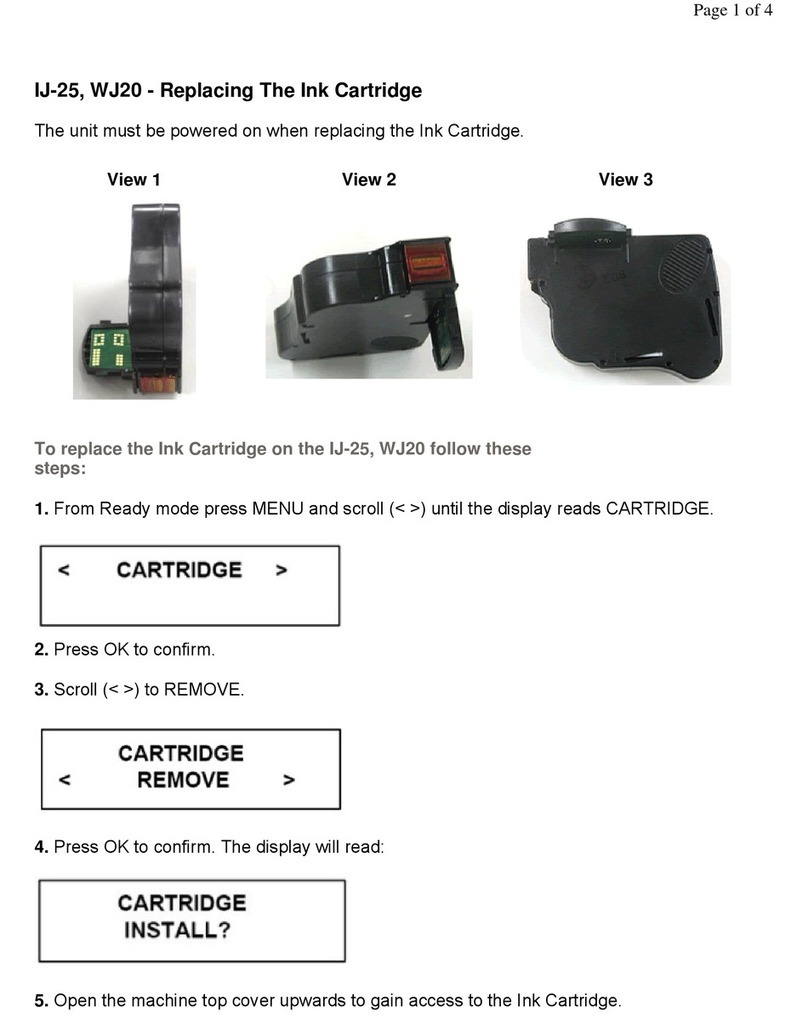

Thehighvolumecapacityandsealedinkcartridgemakesiteasy

andsafetohandle,andtheuserinterfaceisparticularlyclearwith

a graphic interface, pop up menus and 10 memories to store

favoritejobs.

The IJ 70 is adaptable and as such can handle many different

types of mail. The optional feeder can be used to process, in a

continuouscycle,itemsofdifferentsizes(rangingfromDLtoC4

portrait format) and thick items (up to 16 mm), with automatic

imprintshift.Forthickermailitemsorpackages,adhesivelabels

canbeautomaticallydispensed.

The IJ 70 is connectable. It can exchange data with Neopost

platforms and printers in order to provide optimal mail processing

andreporting.

Finally, the IJ 70 is a unique communication tool for your

company. Its high quality printing combined with its integrated

libraryofmessages,mini-diesandfreeformattextwillaffordyou

extratoolstoenhanceyourcompany’simageandtheimpactof

yourmail.

YouwillverysoondiscoverforyourselfthattheIJ70istheultimate

inqualityandproductivityformailprocessingequipment.