MODEL 51 OPERATOR MANUAL OPEX CORPORATION

for safety’s sake…

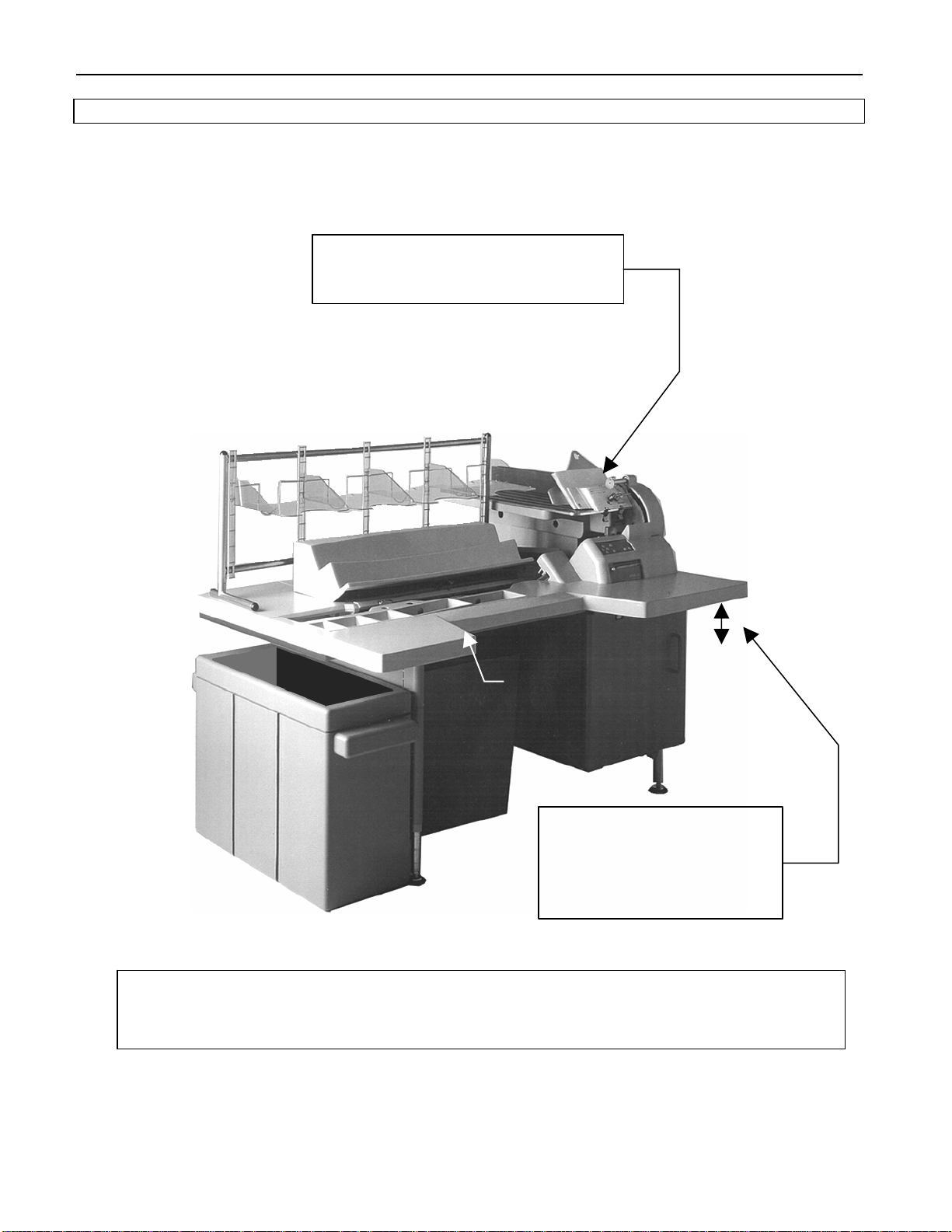

The OPEX Model 51 is designed to allow you to increase your productivity while reducing much of the physical

stress normally associated with your job. Ergonomic considerations will contribute to your comfort as an OPEX

operator. These include the following improvements:

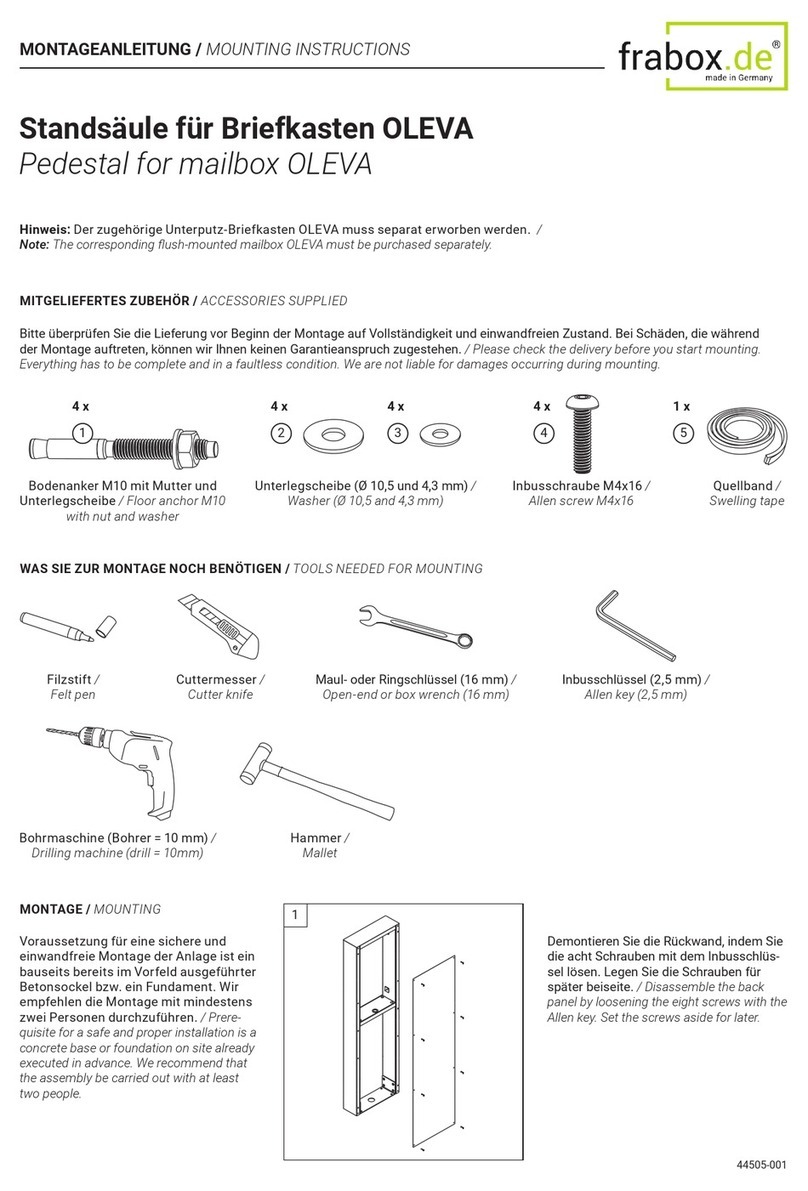

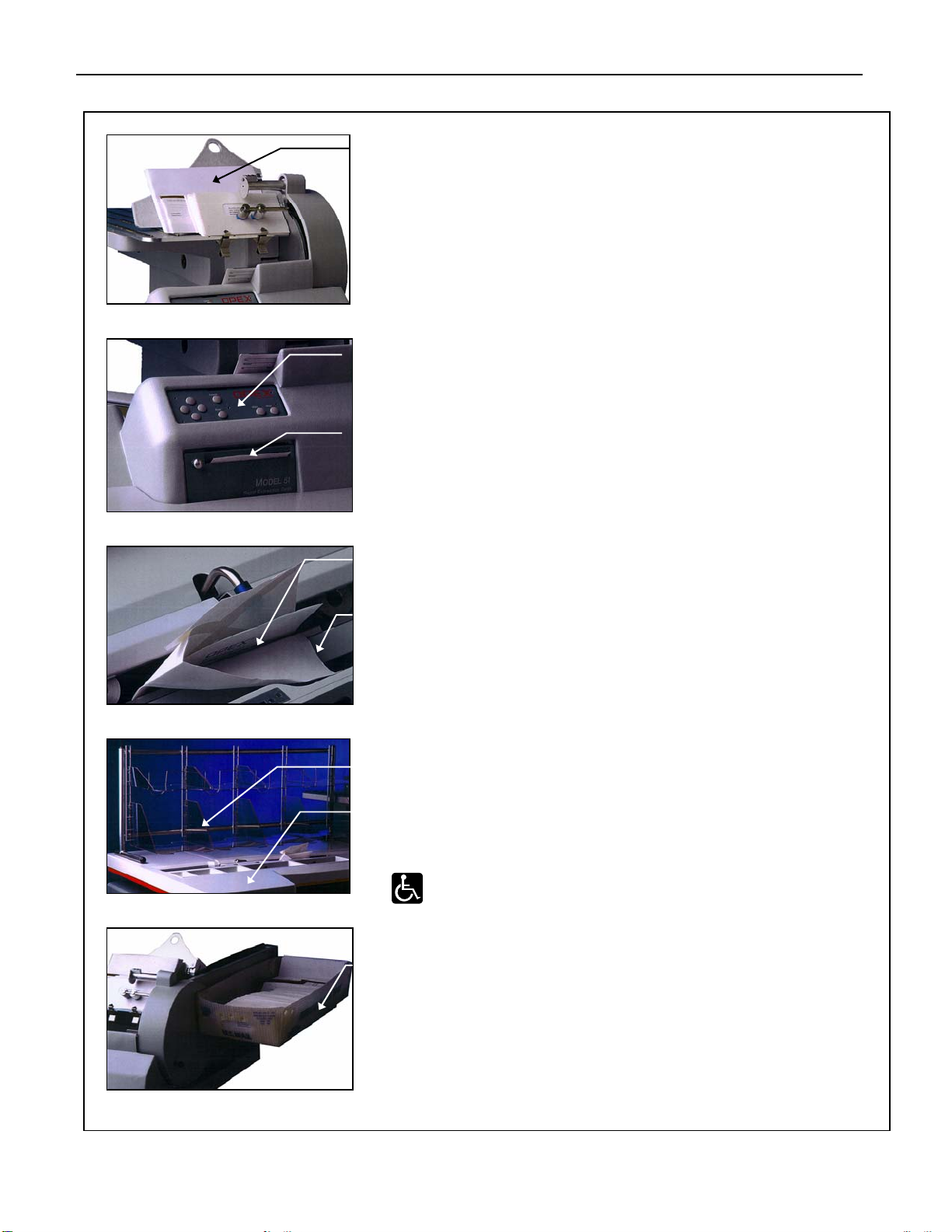

A larger wrap-around work surface gives you room to “spread out.”

Improved envelope extract heads open the envelope wider for easier access.

A vertically oriented sort area reduces arm travel and reach.

An operator-adjustable rack system simplifies large document sorting and placement.

The Performance Control Center is back-lit for easier viewing.

Optional pneumatic height adjustment provides the most comfortable setting for you.

And many other features to make your task easier.

As in any occupation which requires you to perform the same motion repeatedly during the course of

your work, it is important to consider how you perform your task. Always use proper operating

procedures when working at your Model 51 Rapid Extraction Desk. Follow the directions for using and

adjusting your chair and Desk. Using improper procedure can result in a potentially serious injury.

To reduce possible risks, we strongly urge you to follow these suggestions:

1. Maintain an upright body posture. Avoid the tendency to slump in your chair. The angle between

your torso and thigh should always be 90 degrees.

2. Adjust the seat position on your chair so that your elbow, when held at a 90 degree angle at your

side, is approximately 1½ inches below the top of the Model 51 work surface. For your comfort,

we recommend use of a specially-designed OPEX ergonomic desk chair to ensure proper

posture and seat position. The adjustment of the OPEX chair is described in the Accessories

Operation portion of this manual.

3. Occasionally change the angle of your posture.

4. If possible, avoid operating the machine for longer than a single 8 hour shift.

5. If you are under 5’ in height and your Model 51 is equipped with the optional pneumatic height

adjustment, adjust the height of the Desk so that your feet rest on the floor. If your Model 51 is

not equipped with the pneumatic adjustment, you may wish to place your feet on a footrest to

provide greater comfort while operating the machine.

6. If you are over 6’ in height, and your Model 51 is equipped with the optional hydraulic height

adjustment, adjust the height of the Desk so that you are able to work comfortably in a position

which maintains good posture. If your Model 51 is not equipped with the height adjustment,

adjust the leveling feet on the Desk to provide greater extension.

While no suggestions can guarantee completely against work-related injuries, you will certainly increase

your comfort and safety while operating the Model 51 Rapid Extraction Desk if you put these six

suggestions into practice. The Model 51 has been designed with you in mind. If it is operated correctly,

you should find your work experience comfortable and enjoyable.

4