Opex MPS 40 User manual

Other Opex Postal Equipment manuals

Opex

Opex Omation Envelopener 210 Series User manual

Opex

Opex Sure Sort User manual

Opex

Opex Model 72 User manual

Opex

Opex Perfect Pick Cortex User manual

Opex

Opex Envelopener Omation 2100 Specifications

Opex

Opex Falcon+ User manual

Opex

Opex Omation 306 User manual

Opex

Opex Perfect Pick User manual

Opex

Opex Pitnew Bowes Omation 2100 Manual

Opex

Opex Eagle Remittance Processor User manual

Opex

Opex Sure Sort User manual

Opex

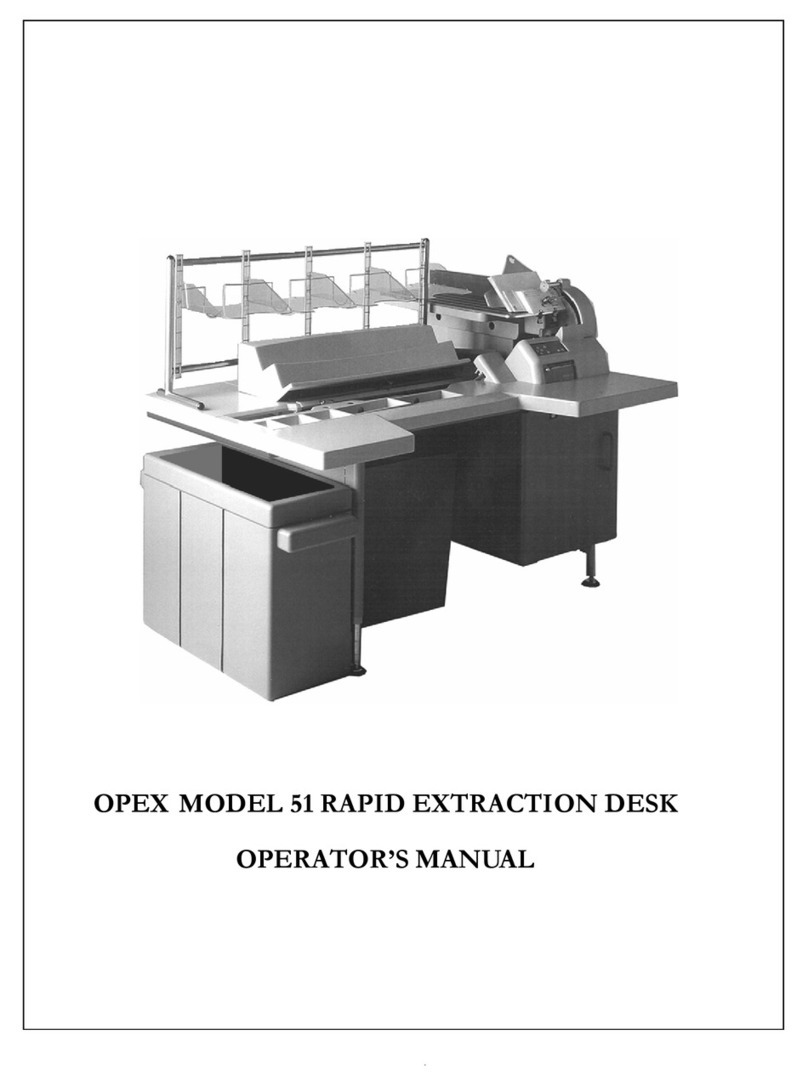

Opex 51 User manual

Opex

Opex Sure Sort User manual

Opex

Opex AS7200 User manual

Opex

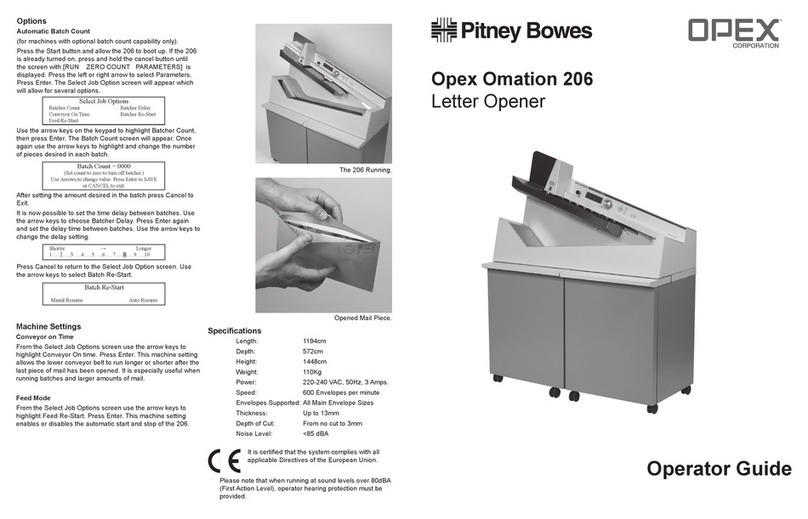

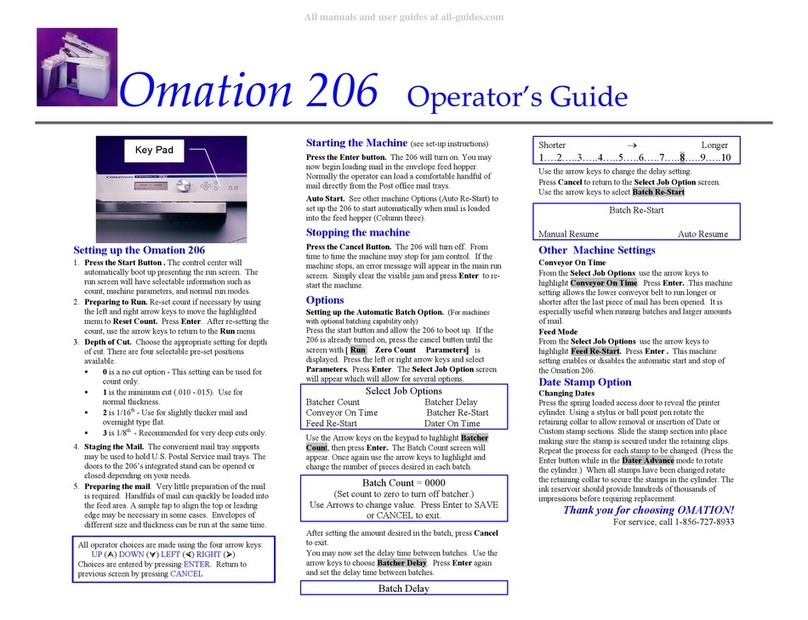

Opex Omation 206 Manual

Opex

Opex Omation 206 Manual

Opex

Opex Omation Envelopener 210 Series User manual

Opex

Opex Omation Envelopener 210 Series User manual

Opex

Opex Envelopener Omation 306 User manual