Table of Contents 5

Omation® Model 306™ Envelopener® Operator Manual

OPEX Corporation use only - not for distribution

Chapter 3

Operation

3.1. Overview of Model 306 Operation ........................................................ 31

3.2. Functional Description .......................................................................... 32

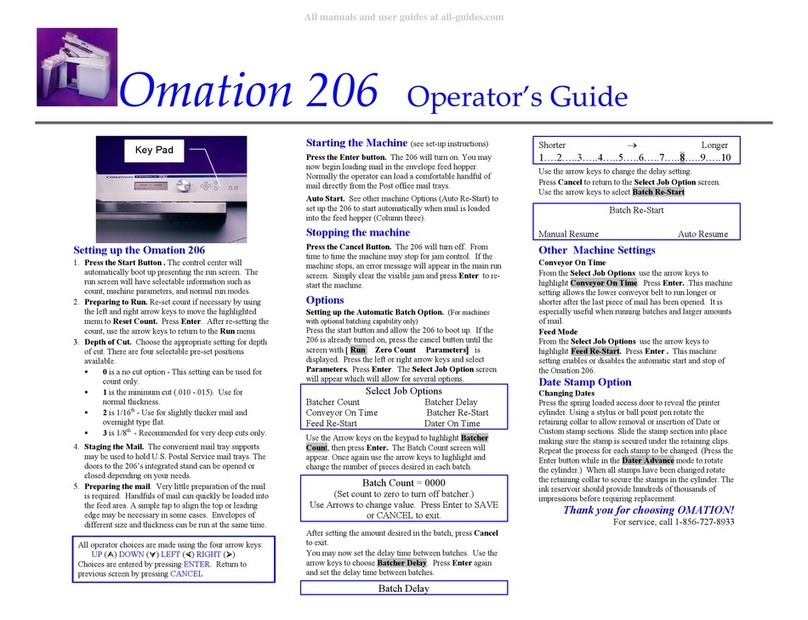

3.3. Machine controls ................................................................................... 33

3.3.1. Enhanced Scrolling ....................................................................... 34

3.3.2. Keypad button functionality ........................................................... 34

3.4. Operating Instructions ........................................................................... 36

3.4.1. The Run screen ............................................................................. 36

3.4.2. Staging the mail ............................................................................. 38

3.4.3. Preparing the mail ......................................................................... 39

3.4.4. Setting the Envelope Height position ............................................ 39

3.4.5. Setting the Thickness Detect position ........................................... 40

3.4.6. Setting the Hi-Speed Inkjet Printer position ................................... 40

3.4.7. Operating the Model 306 ............................................................... 41

3.4.8. Adjust LCD Contrast ...................................................................... 44

3.4.9. Setting and Viewing Operator Passwords ..................................... 44

3.5. Supervisor Operations .......................................................................... 47

3.5.1. Job Menu ....................................................................................... 48

3.5.2. Add Job ......................................................................................... 48

3.5.3. Delete Job ..................................................................................... 49

3.5.4. Modify Job ..................................................................................... 50

3.5.5. Sort Wizard .................................................................................... 52

3.5.6. Copy Job ....................................................................................... 59

3.5.7. Sort List ......................................................................................... 60

3.5.8. Print All Jobs or Individual Job Parameters ................................... 60

3.6. Job Parameters ..................................................................................... 62

3.6.1. Operator Menu .............................................................................. 69

3.6.2. System Configuration Menu .......................................................... 74

3.6.3. Audit Trail Menu ............................................................................ 75

3.6.4. Password Options ......................................................................... 80

3.7. Statistics ................................................................................................ 81

3.7.1. Operator Statistics ......................................................................... 81