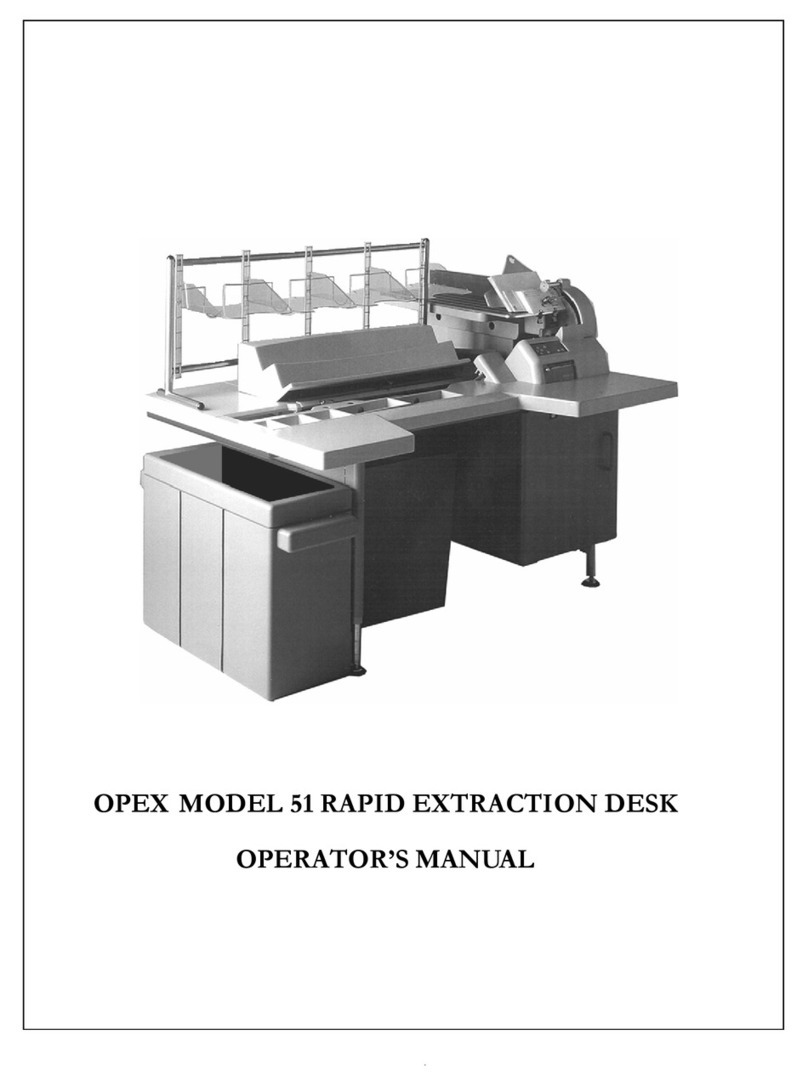

Omation 2100 Envelopener Operator Instructions

Safety Precautions:

•Read and understand all aspects of the

Operator Instructions before operating this

equipment.

•Keep hands, hair, loose jewelry, neckties,

and clothing clear of the feed area during

operation of this unit.

•Lifting and or moving of this equipment

requires two persons.

•Unit must be placed securely on

table/surface that is properly rated for

accumulated load weight.

•Use of this equipment is limited to its

intended function, that of opening mail.

•Before cleaning, make sure all power is

disconnected.

•Do not spray cleaning liquids directly on

this equipment.

•Turn off the machine during periods of

non-use.

•Always turn the power off before removing

the Nip Arm or Chip Bin.

Cut/No Cut Function:

The Omation 2100 is capable of counting

individual pieces of mail with or without milling

open the envelope. This function can be selected

by turning the Cut/No Cut Knob to the desired

selection position.

Note: Adjusting the cutter to the maximum depth

of cut can defeat the “No Cut” Option.

Counter Function:

The Counter counts individual pieces of mail

processed in either the “No Cut” or “Cut” mode.

Even if power is lost to the machine or the machine

is turned OFF, the Omation 2100 will maintain the

count total. Once the Counter is reset, the previous

count is lost. The condition of the mail and the

cleanliness of the machine can effect the accuracy

of the count.

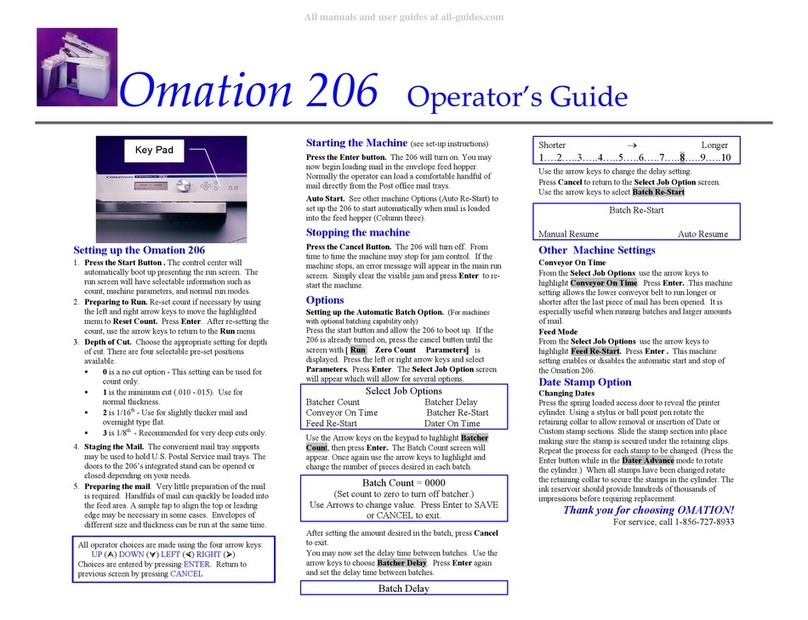

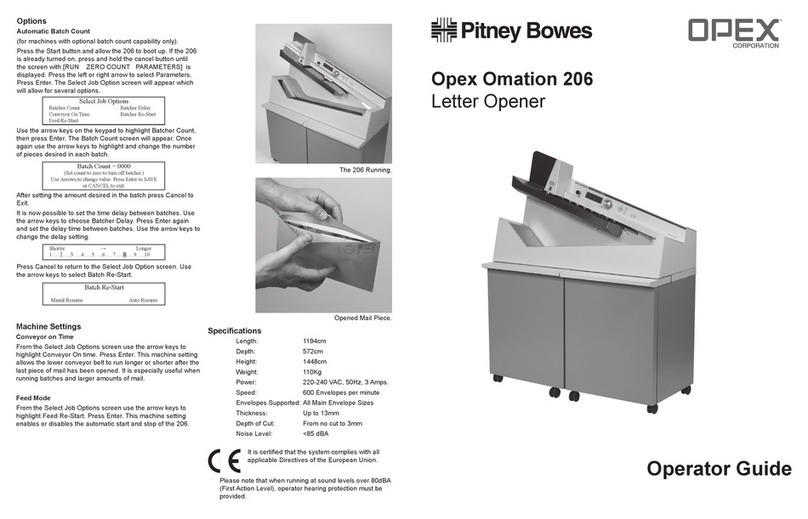

Operating the Omation 2100:

Note: Reference illustration on reverse side

1. Make sure power cord is connected to the

Omation 2100 and the plug is securely

connected to the power receptacle.

2. Select either “No Cut” or “Cut” Position on

the Cut/No Cut Selector Knob (1) located on

the top of the Omation 2100.

3. Reset Counter, if desired, by pressing the

Counter Reset Button (2) located next to the

LED Count Indicator Readout Window (9).

4. Load a handful of mail (approximately 50

pieces) onto the Envelope Feed Hopper (3)

located on the left side of the machine. Be

sure to justify the side of the mail to be cut

against the back of the Feed Hopper.

5. To begin operation, turn the On/Off Power

Switch (4) to the On position. When facing

the front of the machine, the Power Switch is

located on the right end of the machine.

6. Once the Envelope Feed Hopper is empty,

empty the Envelope Catch Tray (5).

7. The Chip Bin Full Indicator Light (11)

located next to the Count Indicator Readout

Window, indicates that the Chip Bin is full

and needs to be emptied. Removal and

replacement of the Chip Bin resets the

indicator.

8. To continue processing, repeat the above

steps.

Cutter Adjustment:

The Omation 2100 will arrive with the cutter preset

from the factory. However, the cutter can be

adjusted to accommodate different mail thicknesses

by turning the Cutter Adjustment Screw. The

Cutter Adjustment Screw may be accessed through

the small hole (7) in the front of the Nip Arm (8)

Turn “OFF” power to the 2100. Insert a

customer-supplied 5/32” long-arm hex wrench

through the small hole and engage the Cutter

Adjustment Screw. Turning the Cutter Adjustment

Screw clockwise will increase the depth of cut,

turning the screw counter-clockwise will decrease

the depth of cut.

Nip Arm Removal/Installation:

The Nip Arm (8) may be removed to facilitate

cleaning of the Omation 2100. To remove the Nip

Arm, turn the machine OFF. Grasp the right end

of the Nip Arm, pulling upward and remove.

Reverse this procedure to re-install the Nip Arm.

The Omation 2100 will not operate until the Nip

Arm is properly installed.

Cleaning the Omation 2100:

Cleaning of the Omation 2100 should be

performed daily after use.

1. Unplug the power Cord

2. Remove the Nip Arm

3. Remove and empty the Chip Bin (10) The

Chip Bin is located under the cutting deck. It

can be accessed by pressing the black pop-out

button, located in the center of the bin and

rotating it in either direction, while pulling

toward the operator. The bin can be

completely removed for easy disposal of

milled chips. To replace the Chip Bin, slide

the bin forward into the machine until

completely in place. Press the button in, to

lock the bin in place. The machine will not

run unless the bin is properly seated and

locked into place.

Note: Be sure to clean the cavity in which the

Chip Bin resides. Build up of chips behind the

Chip Bin can cause the Chip Bin to improperly

seat and prevent the machine from operating.

4. Vacuum loose paper chips from the machine.

5. Use cloth moistened with liquid cleaner such

as WindexTM or Formula 409TM to wipe down

the exterior of the machine.

Note: Do not apply liquid cleaner directly to the

Omation 2100.

6. Re-install Chip Bin and Nip Arm.

See reverse side for

roduct illustration