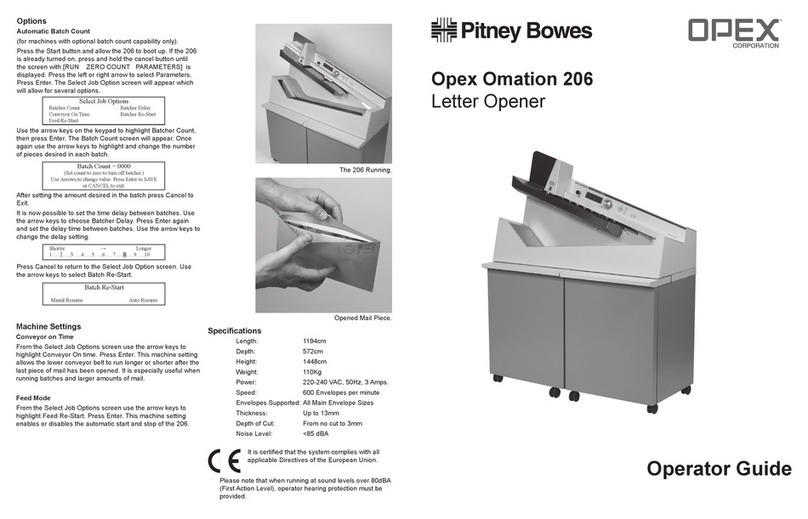

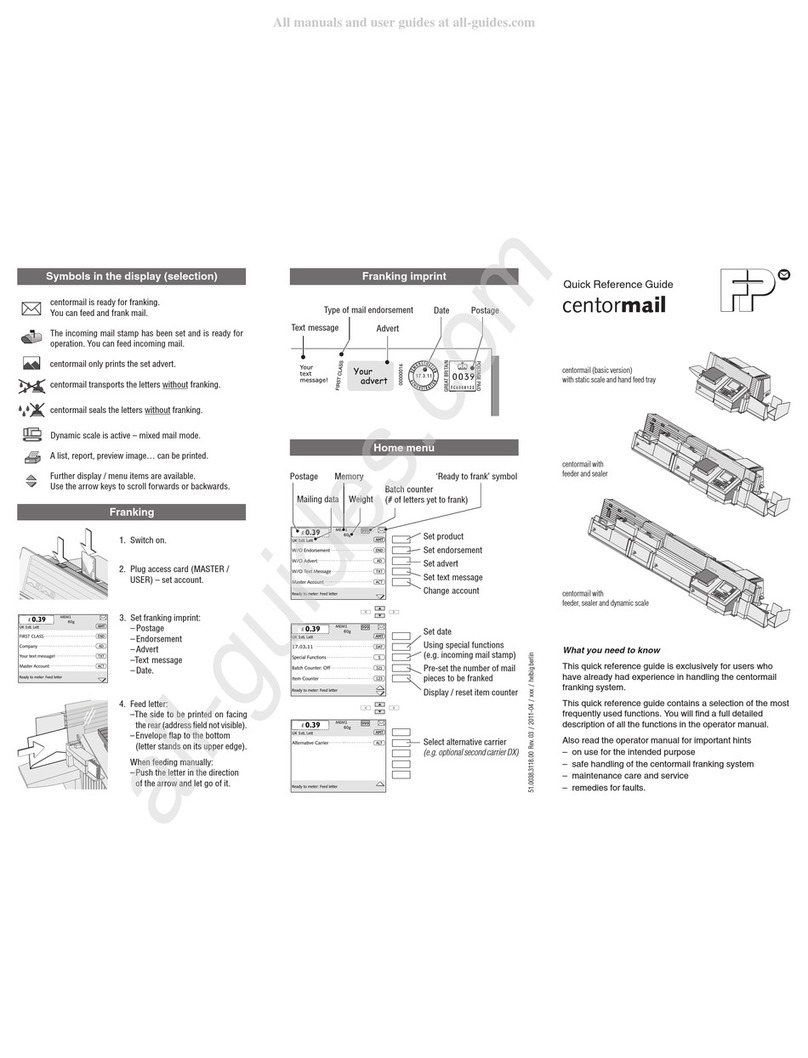

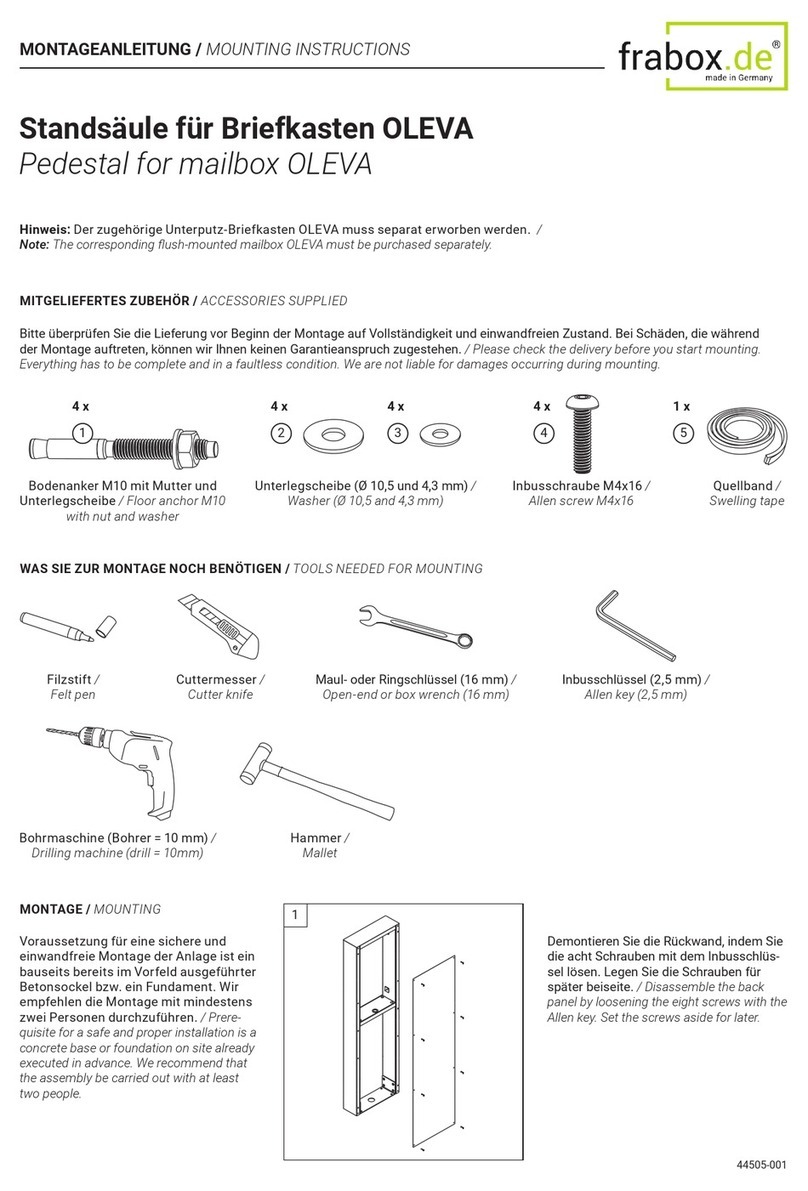

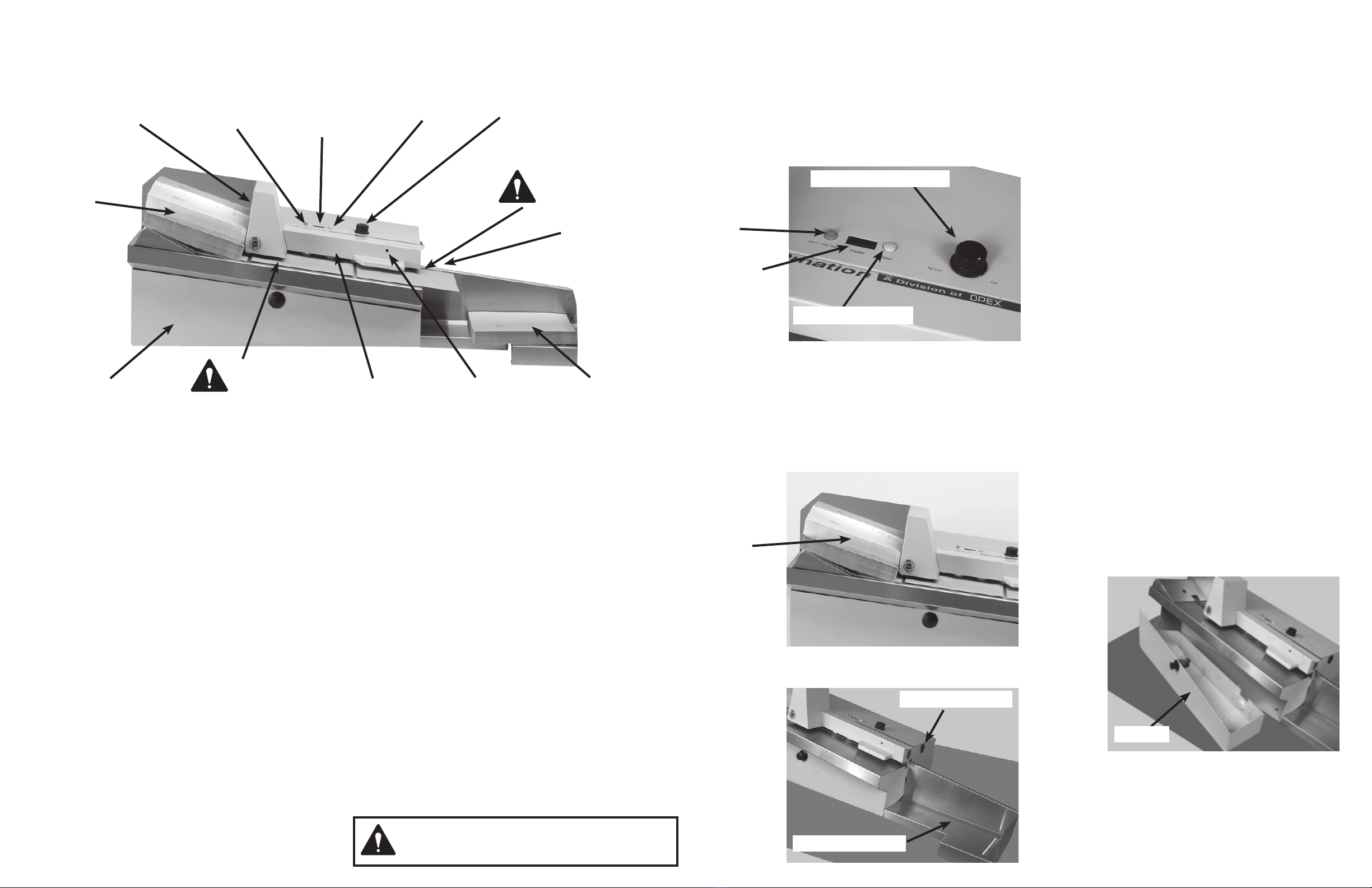

Envelope Feed

Hopper

LED Counter

Indicator Readout

Window

Chip Bin Full

Indicator Light

Counter Reset

Button

Cut/No Cut

Selector Knob

CAUTION!

Pinch Point

Power On/Off

Switch

Envelope

Catch Tray

Cutter Adjustment

Screw Access

Hole

Upper

Transport

Cover

Chip Bin

CAUTION!

Pinch Point

2100 Letter Opener

Identication

Safety

Follow the normal safety precautions for all office equipment:

• Use only Pitney Bowes approved supplies, in particular

aerosol dusters. Improper storage and use of aerosol

dusters or flammable aerosol dusters can cause an

explosive-like condition that could result in personal injury

and/or property damage. Never use aerosol dusters

labeled flammable and always read instructions and safety

precautions on the duster label.

• To obtain supplies, please contact our Supply Line™ to

place orders. Material Safety Data Sheets can be obtained

on the web or from our Supply Line™. Refer to the Contact

Information List for more information.

• Use the power cord supplied with the machine and plug

it into a properly grounded wall outlet located near the

machine and easily accessible. Failure to properly ground

the machine can result in severe personal injury and/or

fire.

• Avoid touching moving parts or materials while the

machine is in use. Keep hands, loose clothing, jewellery

and long hair away from all moving parts.

• Do not remove covers or defeat safety interlock switches.

Covers enclose hazardous parts that should only

be accessed by properly trained service personnel.

Immediately report to service any damaged or non-

functioning components that renders the unit unsafe.

• Place the unit in an accessible location to allow for proper

venting of the equipment and to facilitate servicing.

• The power cord wall plug is the primary means of

disconnecting the machine from the AC supply.

• Do not use an adapter plug on the line cord or wall outlet.

• Do not remove the ground pin from the line cord.

• Avoid using wall outlets that are controlled by wall

switches, or shared with other equipment.

• Do not route the power cord over sharp edges or trap

between furniture.

• Ensure there is no strain on the power cord and that it

does not become jammed between the equipment, walls

or furniture.

• Be certain the area in front of the wall receptacle into

which the machine is plugged is free from obstruction.

• Before clearing a stoppage, be sure machine mechanisms

come to a stop.

• When removing stalled material, avoid using too much

force to protect against minor personal injury and

damaging equipment.

• To prevent overheating, do not cover any vent openings.

• Operation of this equipment without periodic maintenance

will inhibit optimum operating performance and could

cause the equipment to malfunction. Contact your machine

supplier for required service schedule.

• Read all instructions before attempting to operate the

equipment.

• Use this equipment only for its intended purpose.

• Always follow the specific occupational safety and health

standards for your workplace.

WARNING: THIS EQUIPMENT MUST BE EARTHED

The socket outlet should be near to the equipment and

should be easily accessible.

Operation

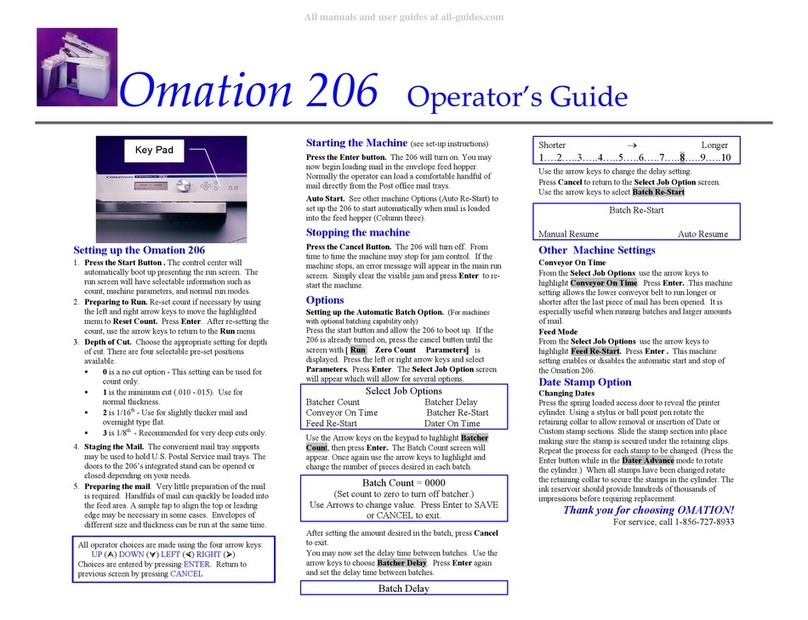

Operating the 2100

1. Make sure the power cord is connected to the 2100

and the plug is securely connected to the power

receptacle.

2. Select either ‘No Cut’ or ‘Cut’ position on the Cut/No

Cut Selector Knob (See pic below) located on the

top of the 2100. See Cut/No Cut Function for more

information.

3. Reset Counter, if desired, by pressing the Counter

Reset Button (See Pic Above) next to the LED Count

Indicator Readout Window. See Counter Function

for more information.

4. Load mail (approximately 50 pieces) onto the Enve-

lope Feed Hopper (See Pic below). Be sure to justify

the side of the mail to be cut against the back of the

Feed Hopper.

5. To begin Operation turn the On/Off Power Switch

(See Pic below) to the On position.

LED Count

Indicator

Readout

Window

6. Once the Envelope Feed Hopper is empty, empty the

Envelope Catch Tray (See Pic on previous column).

7. To continue processing, repeat the above steps.

Cut/No Cut Function

The 2100 is capable of counting individual pieces of mail with

or without opening the envelope. This function can be selected

by turning the Cut/No Cut Knob to the desired selection posi-

tion.

NOTE: Adjusting the cutter to the maximum depth of cut can

defeat the ‘No Cut’ option.

Counter Function

The 2100 Letter Opener counts individual pieces of mail

processed in either the ‘No Cut’ or ‘Cut’ mode. Even if power is

lost to the machine or the machine is turned off, the 2100 will

maintain the count total. Once the count is reset the previous

count is lost. The condition of the mail and the cleanliness of

the machine can effect the accuracy of the count.

Removal/ Replacement and Adjustments

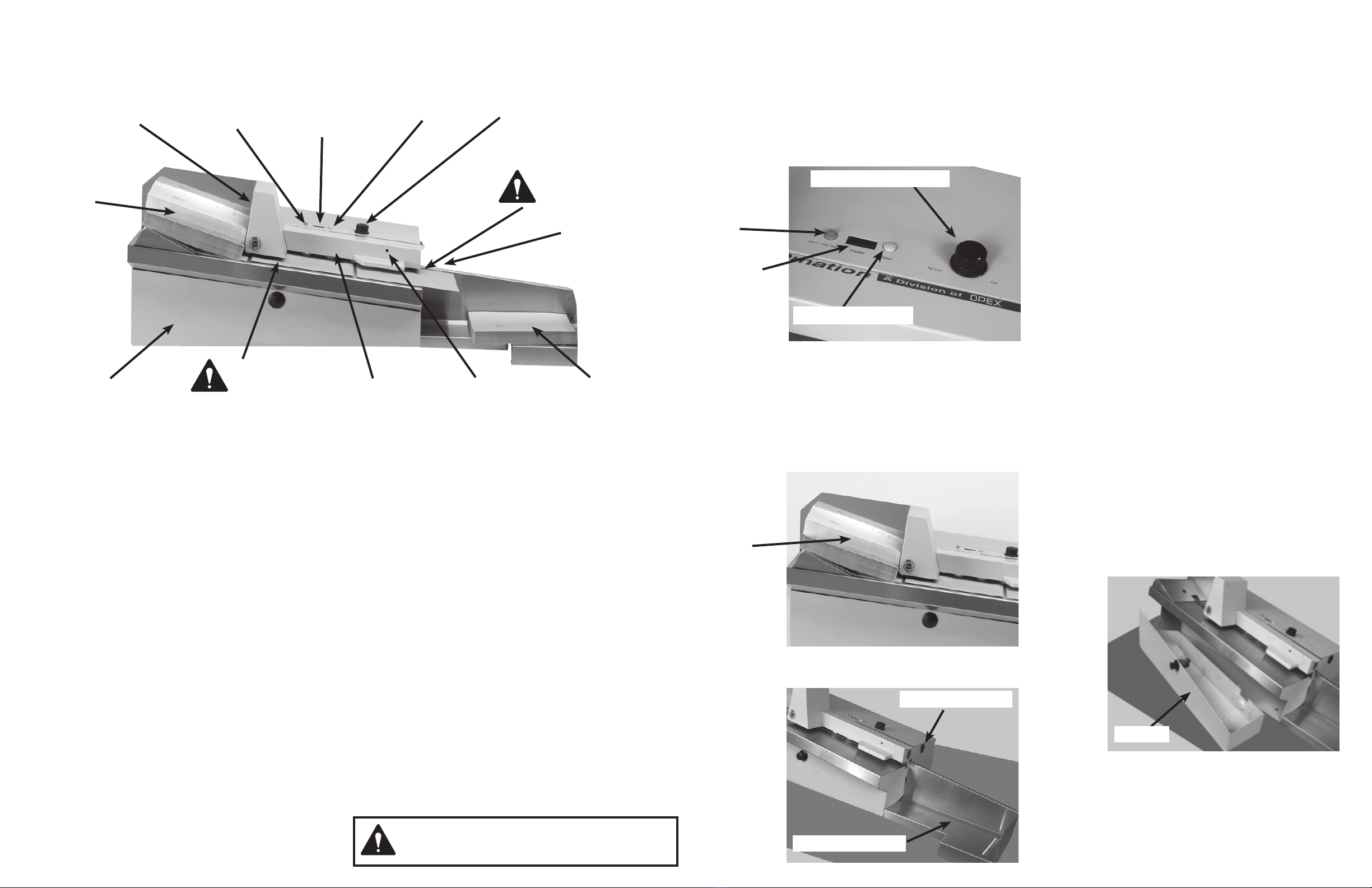

Chip Bin Full

The Chip Bin Full Indicator Light (See pic below) indicates that

the Chip Bin is full and needs to be emptied. Removal and

Replacement of the Chip Bin resets the indicator. The Chip Bin

which is located under the cutting deck can be accessed by

pressing the black pop-out button, located in the centre of the

bin and rotating it in either direction, while pulling towards the

operator. the bin can be completely removed for easy disposal.

To replace the Chip Bin, slide the bin forward into the machine

until completely in place. Press the button in, to lock the bin

in place. the machine will not run unless the bin is properly

locked into place.

NOTE: Be sure to clean the cavity in which the Chip Bin

resides. Build up of chips behind the Chip Bin can prevent the

bin locking into place and the machine from working.

Cut/No Cut Selector Knob

Counter Reset Button

Feed

Hopper

On/Off Power Switch

Envelope Catch Tray

Chip Bin Full

Indicator

Light

Chip Bin

Stone

Adjustment

Screw

Access Hole