INTRODUCTION

1-1 BEFORE YOUR OPERATION 1

1-2 PRECAUTIONS 2

1-3 PARTS IDENTIFICATION 2

PREPARATIONS

2-1 ORDERING DETECTOR BATTERIES 2

2-2

CHECKING THE WIRELESS TRANSMITTER SIZE

2

INSTALLATION

3-1 SEPARATING 3

3-2 WALL MOUNTING 3

3-3 POLE MOUNTING 5

3-4 MOUNTING IN THE BEAM TOWER 6

3-5

MOUNTING EXAMPLE AT PARTICULAR CASE

6

3-6 WIRING 7

SETTING

4-1 FUNCTION 8

4-2 OPTICAL ALIGNMENT 9

4-3 OPTIONAL SETTINGS 10

OPERATION CHECK

5-1 LED INDICATION 10

5-2 OPERATION CHECK 10

TROUBLESHOOTING

6-1 TROUBLESHOOTING 11

DIMENSIONS

7-1 DIMENSIONS 11

SPECIFICATIONS

8-1 SPECIFICATIONS 11

OPTIONS

9-1 OPTIONS 12

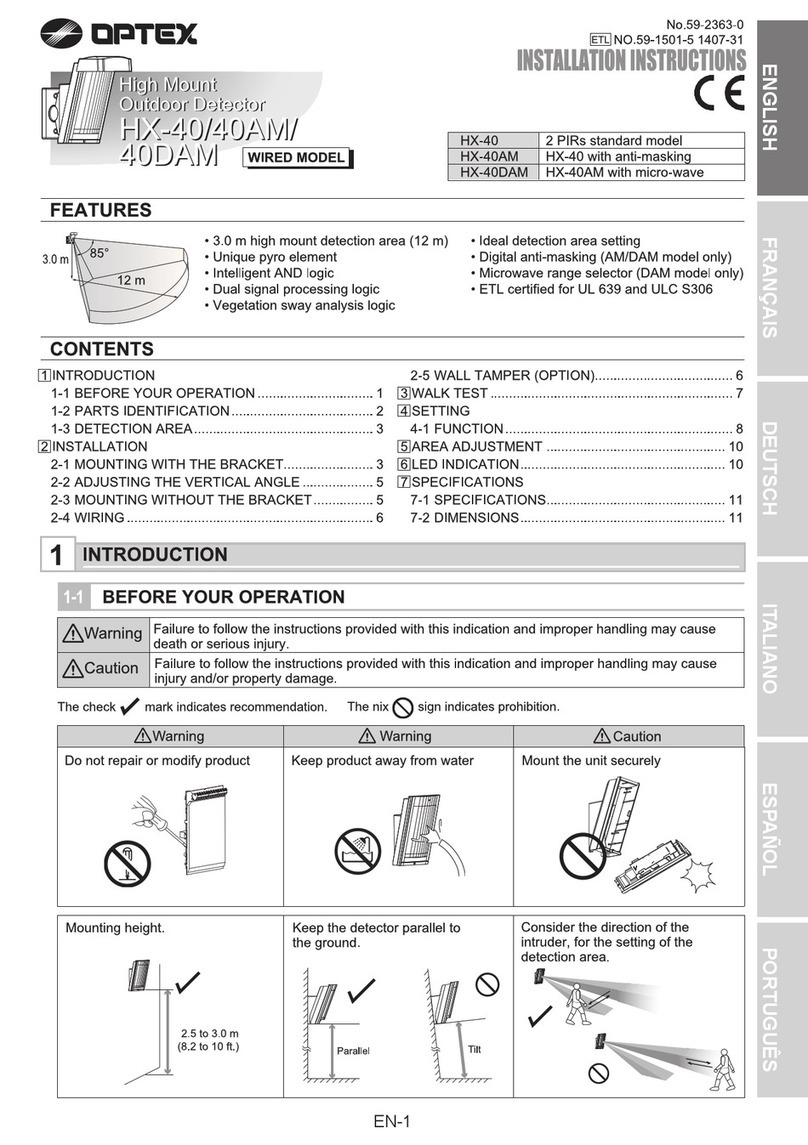

Warning

Caution

Warning

Caution

1

2

3

4

5

6

7

8

9

INSTALLATION INSTRUCTIONS

No. 59-2157-1

CONTENTS

FEATURES

Failure to follow the instructions provided with

this indication and improper handling may cause

death or serious injury.

Failure to follow the instructions provided with

this indication and improper handling may cause

injury and/or property damage.

•Read this instruction manual carefully prior to installation.

•After reading, store this manual carefully in an easily accessible

place for reference.

•This manual uses the following warning indications for correct use

of the product, harm to you or other people and damage to your

assets, which are described below. Be sure to understand the

description before reading the rest of this manual.

This symbol indicates prohibition. The specific prohibited

action is provided in and/or around the figure.

This symbol requires an action or gives an instruction.

INTRODUCTION

1

1-1 BEFORE YOUR OPERATION

Detection range 100m/350ft.

SL-350 QFR

SL-350 QNR

Detection range 100m/350ft.

4 selectable beam frequencies

•

Battery-operated detector

- Battery life:

Transmitter Approx. 4 years (2 in the transmitter)

Receiver Approx. 5 years (2 in the receiver)

(when using LSH20 (3.6V, 13Ah) batteries manufactures by SAFT)

- Up to 8 batteries (4 in the transmitter, 4 in the receiver)

(normal operation requires 2 batteries)

- Battery saving function

- Intermittent output function

- Spacious back box for numerous wireless transmitters

•Quad high power beams

•Smart design

- Slim body design

- Easy-to-see vivid interior color for optical alignment

-

IP65

waterproof

structure

•

4 channel beam frequency selector (SL-350QFR only)

• Viewfinder with 2X magnification

•

Beam interruption adjustment function

•

D.Q. circuit (environmental disqualification)

•

Tamper function

•

LED indicator for an easy alignment

•Various options (refer to page 12)

( ABC-4, BC-4, BCU-4, PSC-4, SBU-4, BAU-4, EC-4 ) Do not use the product for purposes other than the detection

of moving objects such as people and vehicles.

Do not use the product to activate a shutter, etc., which may

cause an accident.

Do not touch the unit base or power terminals of the

product with wet hands (do not touch when the product

is wet with rain, etc.). It may cause electric shock.

Never attempt to disassemble or repair the product. It may

cause fire or damage to the devices.

Do not use batteries that have different levels of power

remaining (i.e., new and used batteries).

Not observing the above may result in an explosion, leakage

of electrolyte, emission of toxic gases or other outcomes that

may be harmful to people and property.

[Handling of Batteries]

Do not recharge, short circuit, crush, disassemble, exceed

heat above 100°C (212°F), incinerate, or expose contents to

water. Do not solder directly to the cell.

Not observing the above may result in fire, explosion or

severe burn hazard.

Do not solder directly to the cell.

Do not pour water over the product with a bucket, hose, etc.

The water may enter, which may cause damage to the

devices.

Clean and check the product periodically for safe use. If any

problem is found, do not attempt to use the product as it is

and have the product repaired by a professional engineer or

electrician.

BATTERY OPERATED

PHOTOELECTRIC DETECTOR

Smart Line series

BATTERY OPERATED

PHOTOELECTRIC DETECTOR

Smart Line series

™

™

ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL PORTUGUÊS

EN-1