4

3

4

5

IMPORTANT SAFEGUARDS

• The machine should be positioned on sturdy and level surface

• While binding, do not put your fingers into the binding slot

• Be careful when moving the wedge (heavy)

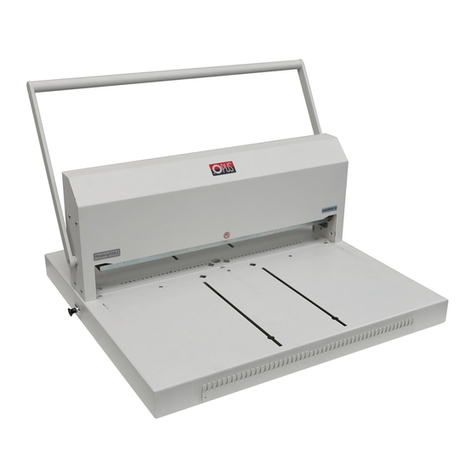

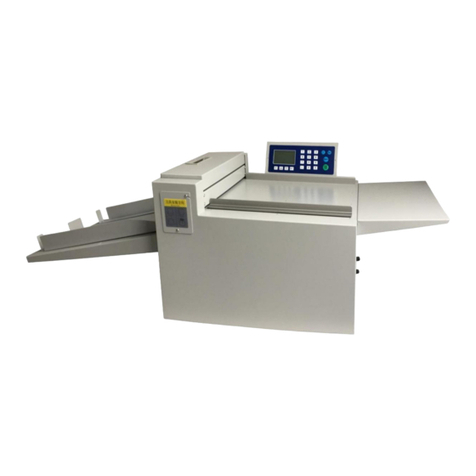

PREPARATION TO WORK

Unpack the machine and install the metal bail on the housing (the adequate holes are

drilled in the housing and screwed bolts). Screw the arm (1) to the machine using the allen

wrench attached. In the shelves at the bottom of the machine there are two guide&bind bar

and B and debinding wedge.

Three bars are included to the machine: magnetic guiding bar (1) - with magnet, allows to

insert the documentation into the channel easily, guide&bind bar (8) thin - with a ruler, to

be used with 20-32 size channels, helps to insert the document into the channel,

guide&bind bar (9) thick - with a ruler, to be used with 5-16 size channels, allows to place

the document into the channel and reduces the size of the binding slot. The shape of bars

is specially designed to make inserting the documentation in the channel as easy as possible.

Put the magnetic guiding bar (7) on the movable binding jaw and insert the guide&bind

bar (8/9) by the back wall of the binding slot (3). The cut side of each bar should be directed

to the inside of the binding slot (3).

The machine is ready to work.

BINDING

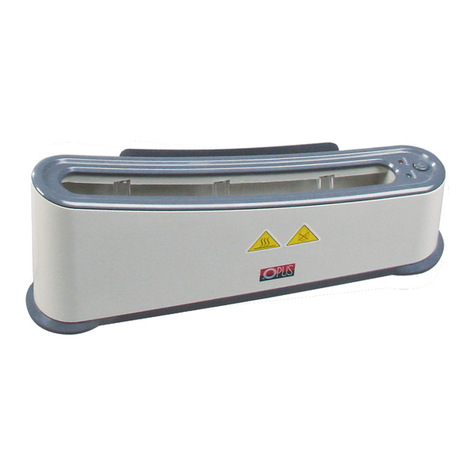

Important! If you are going to use Atlas 300 to bind and hot stamp on the same cover, re-

member to hot stamp an inscription first and then bind the document. Therefore, in such

case, before binding refer to the user`s guide of Image Press device (on the following

pages of this manual) to make the hot stamping.

1. Use the device (6) to choose the proper channel size (when measuring the thickness use

only sheets without covers). The channel sizes and corresponding number of pages you

can bind with them are shown in the table.

/p/ – hard cover/pile of pages/ hard cover

/p/T – hard cover/pile of pages/transparent cover

S/p/S – soft cover/pile of pages/soft cover

O/p/O – pile of pages bound only with a channel

Channel size H/p/H H/p/T S/p/S O/p/O

5 (MINI) 18-3 18-33 18-34 18-38

7 32-60 34-63 35-63 39 - 67

10 61-89 64-92 64 - 92 68 - 97

13 90-118 93-121 93 - 121 98 - 126

16 119-148 122 - 150 122 -150 127 - 155

20 149 – 186 151 – 189 151 – 189 156 – 194

24 187 – 225 190 – 228 190 – 228 195 – 233

28 226 – 264 229 – 266 229 – 267 234 – 271

32 265 – 303 267 – 305 268 – 308 272 – 310

5

Atlas 300 Mono • User’s guide GB

Important! The thickness of the documentation to be bound must be at least 1,8 mm

(with the cover). If the documentation is thinner, it is necessary to use the filling strips

(e.g. O.Filling Sticky available from OPUS) to make it thick enough.

2. Make sure the binding bars are correctly inserted into the binding slot (3) (see:prepara-

tion to work).

Important!

• for 5-16 mm channels - insert a thick guide&bind bar (9) by the back wall of the binding slot

• for 20-32 mm channels - insert a thin guide&bind bar (8) by the back wall of the binding slot

3. Set the bail so that the cover is parallel to the debinding plate.

4. Lift the arm (1) maximally up.

5. Move the adjusting handle (2) maximally to the left

6. Insert the channel in-between the bars (7 and 8/9). If using A4 format, move the chan-

nel maximally to the right, close to the side limiter (10). In case of a duct smaller than A4,

apply a movable limiter (dependent on insert used, apply an adequate 11(9) or 11(8)

limiter). The position of movable limiter can be determined by means of a scale on insert

(position = half of duct length).

7. Move the adjusting handle (2) to the right until you feel the resistance.

8. Even a pile of paper, put it between the covers; check if the pages are centered in rela-

tion to the edges of covers.

9. Put the documentation into the channel.

• If using A4 format, move the documentation maximally to the right, close to the side

limiter (10). Make sure the pages are placed in-between the channel incisions (except for

5mm O.C ANNELS and all O.SIMPLE C ANNELS which do not have incisions)

Note! Make sure the back cover is placed in front of you.

10.Press the arm (1) down holding the documentation at the same time and then lift the arm

(1) up.

11. Move the adjusting handle (2) to the left to take out the bound documentation.

back cover

Important!

In some cases (e.g. too big channel size

comparing with the number of pages) it

may happen that the documentation is

not bound properly. In such case, after

lifting the arm (1), move the handle (2) to

the right until you feel the resistance and

then repeat step 9.

BINDING