CHAPTER 1

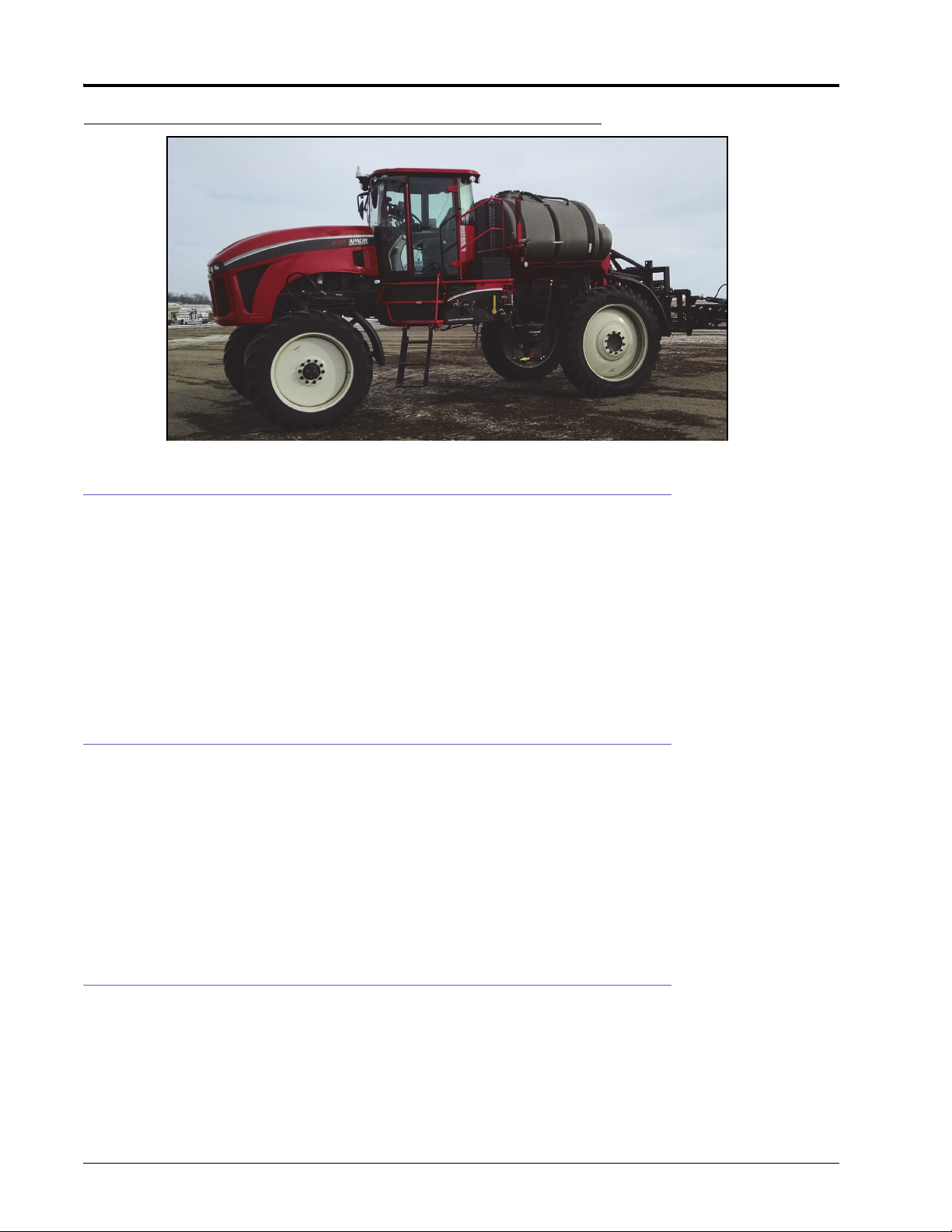

2 Hawkeye® Installation Manual for ET Apache AS 720, 730, 1020, 1025, 1030, 1220, and 1230 Series

•Thoroughly wash hands and face after using agricultural chemicals and before eating, drinking, or

using the rest room.

•Thoroughly flush or rinse equipment used to mix, transfer, or apply chemicals with water after use

or before servicing any component of the application system.

• Follow all federal, state, and local regulations regarding the handling, use, and disposal of agricultural

chemicals, products, and containers. Triple-rinse and puncture or crush empty containers before disposing of

them properly. Contact a local environmental agency or recycling center for additional information.

INSTRUCTIONS FOR WIRE ROUTING

The word “harness” is used to mean all electrical leads and cables, bundled and unbundled. When installing

harness, secure it at least every 30 cm (12in) to the frame. Follow existing harness as much as possible and use

these guidelines:

Harness should not contact or be attached to:

• Lines and hoses with high vibration forces or pressure spikes

• Lines and hoses carrying hot fluids beyond harness component specifications

Avoid contact with any sharp edge or abrading surfaces such as, but not limited to:

• Sheared or flame cut edges

• Edges of machined surfaces

• Fastener threads or cap screw heads

• Ends of adjustable hose clamps

• Wire exiting conduit without protection, either ends or side of conduit

• Hose and tube fittings

Routing should not allow harnesses to:

• Hang below the unit

• Have the potential to become damaged due to exposure to the exterior environment. (i.e. tree limbs, debris,

attachments)

• Be placed in areas of or in contact with machine components which develop temperatures higher than the

temperature rating of harness components

• Wiring should be protected or shielded if it needs to route near hot temperatures beyond harness component

specifications

Harnessing should not have sharp bends

Allow sufficient clearance from machine component operational zones such as:

• Drive shafts, universal joints and hitches (i.e. 3-point hitch)

• Pulleys, gears, sprockets

• Deflection and backlash of belts and chains

• Adjustment zones of adjustable brackets

CAUTION