MOBI360 Table of contents page 2

1 Table of contents

1 Table of contents ...................................................................................................2

2 EC Declaration of Conformity...............................................................................4

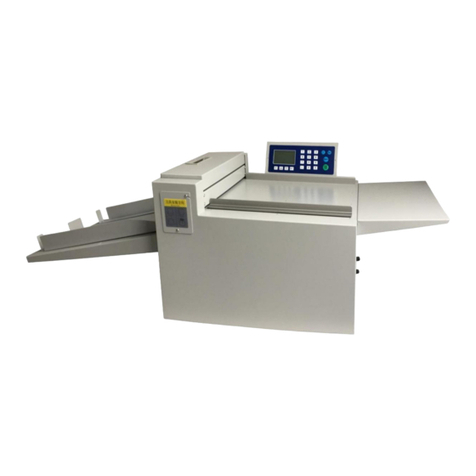

3 As-delivered condition of your MOBI360.............................................................5

4 Product description...............................................................................................6

5 General safety advice............................................................................................7

6 Transport and start-up.........................................................................................11

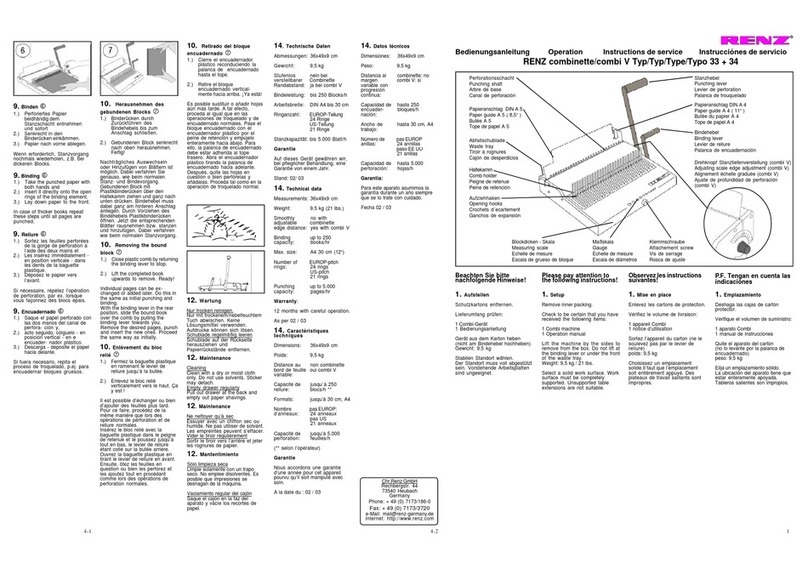

7 RENZ MOBI360 - technical data..........................................................................14

8 RENZ RING WIRE ®Table....................................................................................15

9 Control console and switch................................................................................16

9.1.1 Start screen....................................................................................................................................................17

9.1.2 Settings ..........................................................................................................................................................17

9.1.3 Input screen....................................................................................................................................................17

9.1.4 Parameters:....................................................................................................................................................18

9.1.5 Reference run:................................................................................................................................................18

9.1.6 Automatic mode: ............................................................................................................................................18

10 Setting up the MOBI360.......................................................................................19

10.8.1 Adjusting the stroke limiter:............................................................................................................................23

10.8.2 Adjusting the rear guide rail ...........................................................................................................................24

10.8.3 Adjusting the front guide rail...........................................................................................................................24

10.8.4 Adjusting the clamping...................................................................................................................................25

4.1 Intended use................................................................................................................................6

4.2 Description of operation.............................................................................................................6

4.3 Description of operational sequence ........................................................................................6

5.1 Operator’s duty of care ..............................................................................................................7

5.2 Safety advice...............................................................................................................................7

5.3 Explanation of Symbols .............................................................................................................8

5.4 Safety precautions during normal operation............................................................................9

5.5 Safety precautions during maintenance...................................................................................9

5.6 Work on electrical equipment..................................................................................................10

5.7 Environmental standards.........................................................................................................10

6.1 Safety advice regarding transport...........................................................................................11

6.2 Unpacking the machine............................................................................................................11

6.3 Lifting points when transporting with industrial trucks.........................................................12

6.4 Space requirements and assembly .........................................................................................12

6.5 Electrical connections..............................................................................................................13

6.6 Start- up.....................................................................................................................................13

7.1 Binding formats........................................................................................................................14

7.2 Electrical connections..............................................................................................................14

7.3 Space requirement....................................................................................................................14

7.4 Site conditions..........................................................................................................................14

7.5 Weights......................................................................................................................................14

9.1 Individual screens.....................................................................................................................16

10.1 Changing the RING WIRE spool ..............................................................................................19

10.2 Track of separation paper........................................................................................................19

10.3 Cover for small sizes................................................................................................................20

10.4 Paper guiding rail......................................................................................................................20

10.5 Changing the feed wheel (2:1 or 3:1 pitch) .............................................................................21

10.6 Set up of the feeding section...................................................................................................22

10.7 Adjusting the guide slot on the hanger station ......................................................................23

10.8 Adjusting the closing unit........................................................................................................23