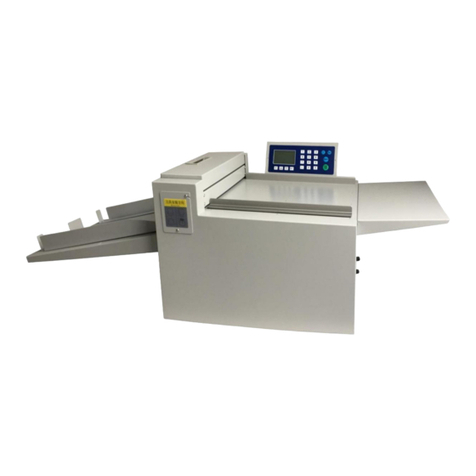

AB500HS

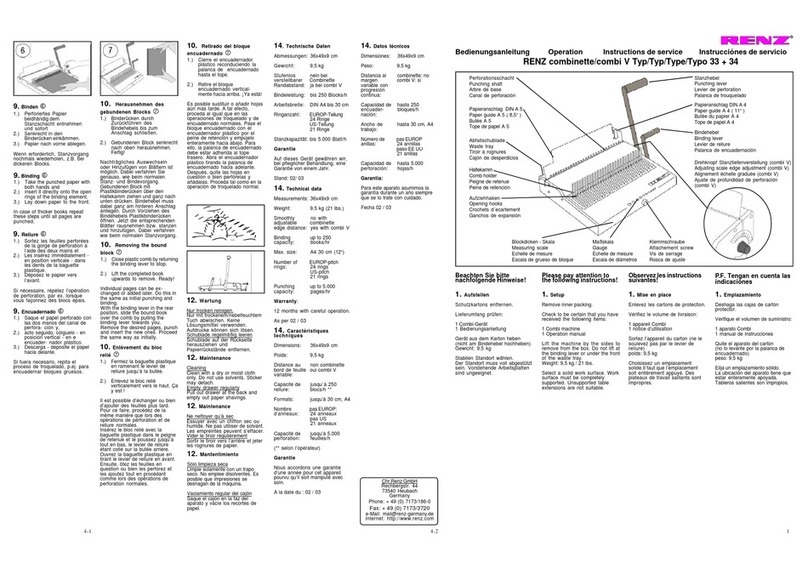

Table of contents page 1

1 Table of contents

1Table of contents ................................................................................................................. 1

2EG conformity declaration .................................................................................................. 3

3AB500HS specific machine datas ...................................................................................... 4

4General Information.............................................................................................................5

4.1 Intended Use..................................................................................................................................................5

4.2 Operating description .....................................................................................................................................5

4.3 Sequence of operation ...................................................................................................................................5

5General Safety Instructions ................................................................................................ 6

5.1 User´s Duty of Care .......................................................................................................................................6

5.2 Safety Instructions..........................................................................................................................................6

5.3 Description of symbols ...................................................................................................................................6

5.4 Safety Requirements for Normal Operation...................................................................................................7

5.5 Safety Requirements for Maintenance and Servicing....................................................................................7

5.6 Working on Electrical Equipment ...................................................................................................................8

5.7 Working on Pneumatic Equipment.................................................................................................................8

5.8 Environment Protection Regulations..............................................................................................................8

6Transport and Installation................................................................................................... 9

6.1 Safety Instructions for Transport....................................................................................................................9

6.2 Unpack the AB500HS ....................................................................................................................................9

6.3 Support points for transportation..................................................................................................................10

6.4 Space requirement with simple output tray..................................................................................................10

6.5 Space requirement with conveyor (shingle) belt..........................................................................................11

6.6 Electrical connection ....................................................................................................................................11

6.7 Installation ....................................................................................................................................................12

6.8 Installation of the de-spooling device...........................................................................................................12

7RENZ Autobind 500 - Technical data ............................................................................... 13

7.1 Binding format ..............................................................................................................................................13

7.2 Electrical connection ....................................................................................................................................13

7.3 Dimensions ..................................................................................................................................................13

7.4 Environmental conditions.............................................................................................................................13

7.5 Pneumatic requirement ................................................................................................................................13

7.6 Weights ........................................................................................................................................................13

8RENZ RING WIRE®Chart................................................................................................... 14

9Touch-screen display and switches................................................................................. 15

10 Adjustable machine elements ....................................................................................... 16

10.1 Paper side stops.......................................................................................................................................16

10.2 Clamping rail.............................................................................................................................................16

10.3 Table height adjustment ...........................................................................................................................16

10.4 Table front stop position ...........................................................................................................................16

10.5 Closing limiter ...........................................................................................................................................17

10.6 Opening limiter .........................................................................................................................................17

10.7 Simple output tray (optional) ....................................................................................................................17

10.8 Conveyor (shingle) belt.............................................................................................................................18

10.9 Maintenance unit for compressed air .......................................................................................................18

11 Handling of the touch-screen-display........................................................................... 19

11.1 Appearing screens....................................................................................................................................19

11.1.1 Starting screen......................................................................................................................................19

11.1.2 Set up screen........................................................................................................................................19

11.1.3 Operation mode (main menue).............................................................................................................19

11.1.4 Automatic ..............................................................................................................................................20

11.1.5 Manual Operation .................................................................................................................................20

11.1.6 Step by step ..........................................................................................................................................20

11.1.7 Inlet check.............................................................................................................................................21

11.1.8 Display messages.................................................................................................................................21

11.1.9 Input box ...............................................................................................................................................23

11.2 Example 1 for 3:1 pitch (Standard A4 book) ............................................................................................23

11.3 Example 2 for 3:1 pitch (with calendar hanger)........................................................................................25