5

2General information

The Multi-Mix controller is a universal weather

regulator made in advanced technology that

allows you to manage the operation of the entire

heating system, as well as the main and

additional source of heat.

In the Multi-Mix standard, it controls two

adjustable heating circuits, one direct circuit and

the charging of the DHW tank. It is adapted to

operate the solar system and can implement

diagrams with a hydraulic coupling or buffer.

The controller can be connected to a boiler

equipped with ON-OFF type contact and control

it smoothly by modulating 0-10V. The controller

can control the pump and the valve switching

additional heat sources, e.g. in the form of a

fireplace with a water jacket.

Using the controller for other purposes than its

intended use is forbidden. Manufacturer does

not bear any responsibility for any loss caused

by such use.

The controller can be used within the household

and in small industrial buildings.

3Information about documentation

The user’s manual of the controller is a

complementation of boiler documentation. In

particular it is necessary to apply the boiler

documentation. The user’s manual of the

controller is divided into two parts: for the user

and for the installer. However in both parts vital

information concerning safety is included. That

is why the user should get aquainted with both

parts of the user’s manual.

We do not take responsibility for damages

caused by failing to observe the following user

manual.

4Documentation storage

This assembly and operation manual, as well as

any other applicable documentation, should be

stored diligently, so that it was available at any

time. In the case of removal or sale of the

device, the attached documentation should be

handed over to the new user / owner.

5Symbols used

Following graphic symbols are used in the user

manual:

- for relevant information and tips,

- for vital information related with issues

of property damage, health and life risk

of humans or domestic animals.

Attention: by these symbols vital information is

marked. It is to allow easy understanding of the

user manual. User and installer is however

required to observe recommendations not

expressed by graphic symbols!

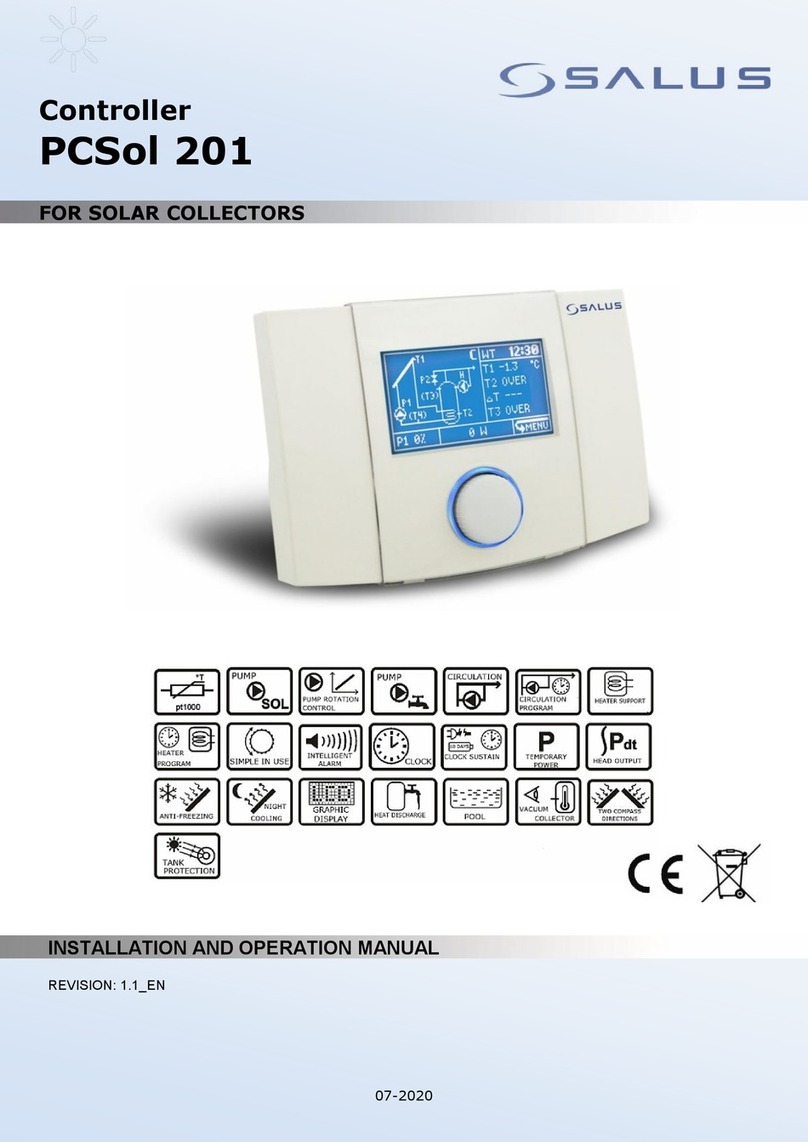

Informations about other icons:

- water pump of direct circuit

(nonadjustable),

- water pump of adjustable circuit,

- DHW tank, charging pump,

- DHW, circulating pump,

- solar pump,

- ON-OFF thermostat/room

thermostat (thermostat with shorted contacts

when calling for heating); or wireless

temperature controller (transmitter + receiver

with COM/NO contacts); or - for example - an

underfloor heating system that affects the

heating circuit through the COM/NO contacts of

the wiring centre (COM/NO contacts are shorted

when system is calling for heating),

- mixing valve,

- heat source controlling by volt-free

contact,

- heat buffer,

- outside temperature sensor,

- weather control,

- summer/winter mode,