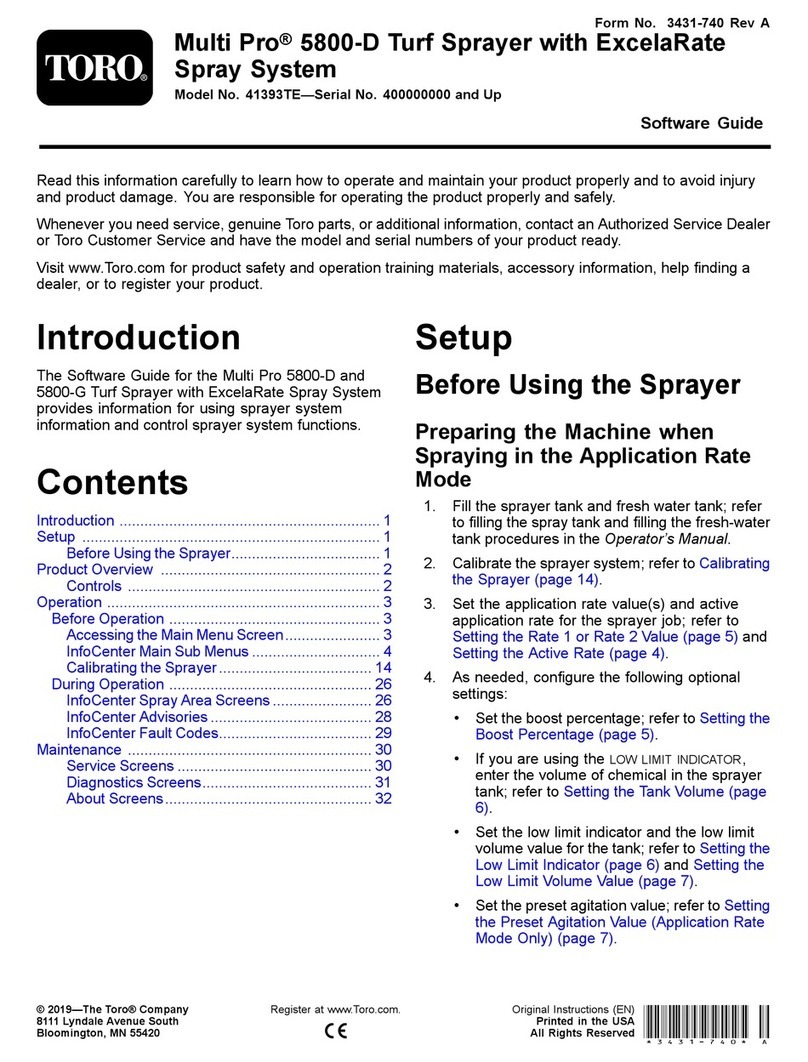

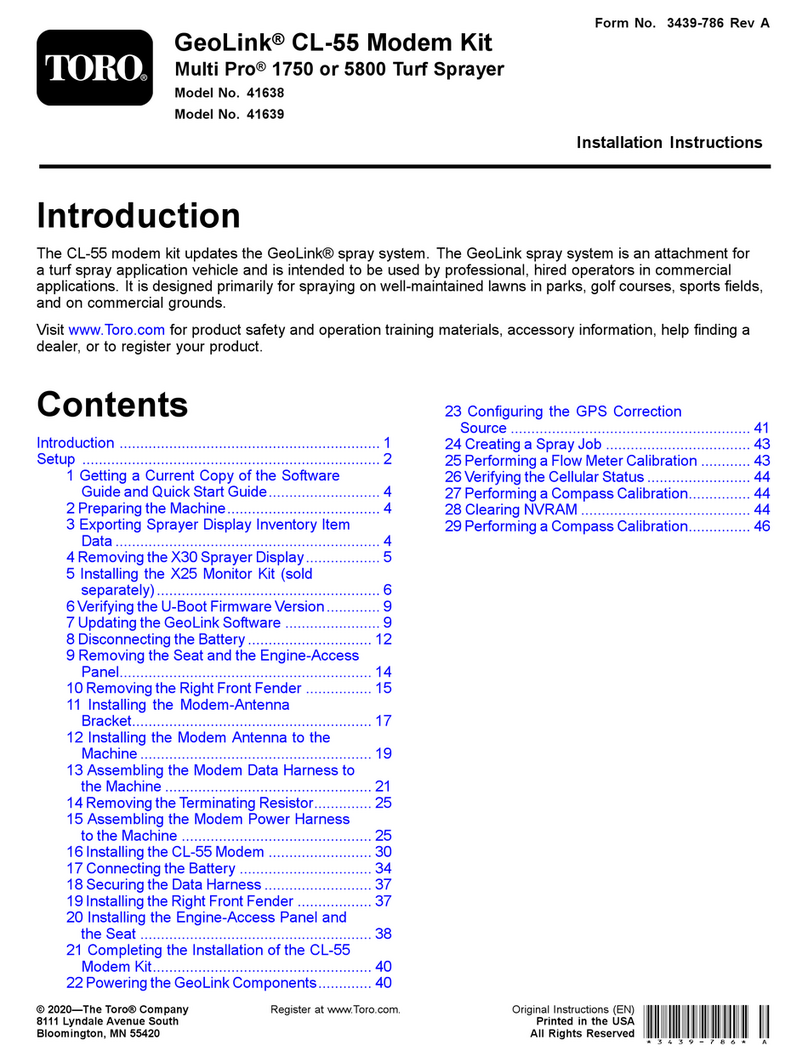

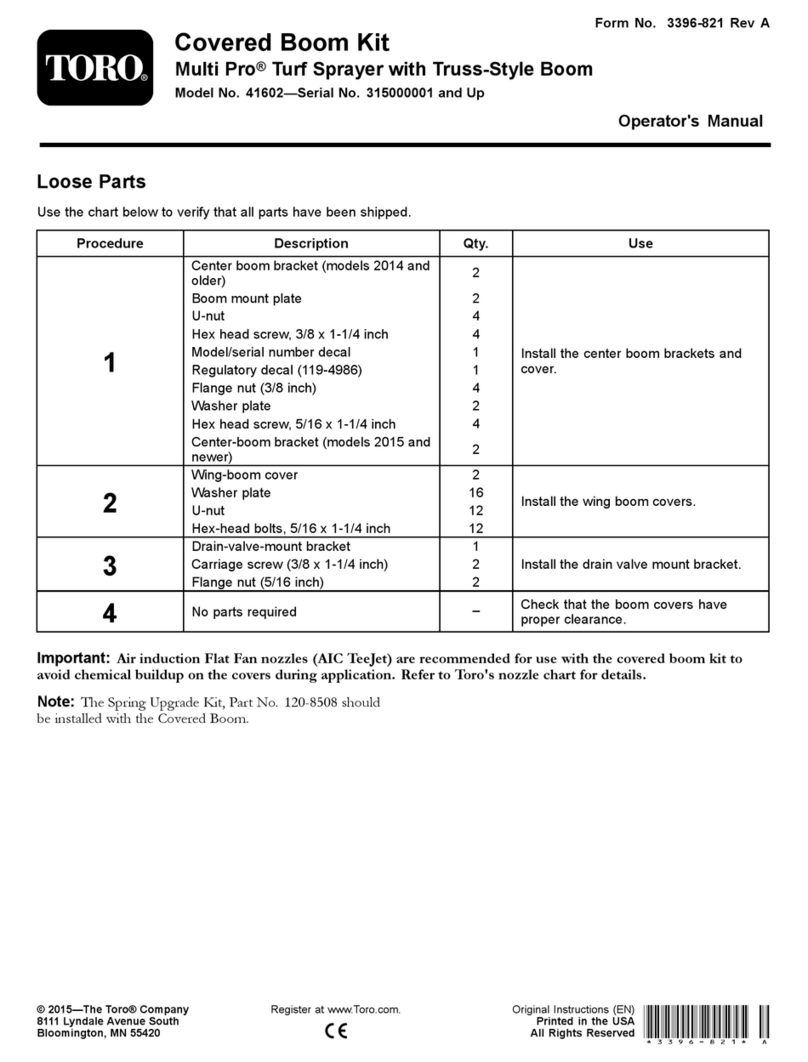

Contents

Safety.......................................................................4

GeneralSafety...................................................4

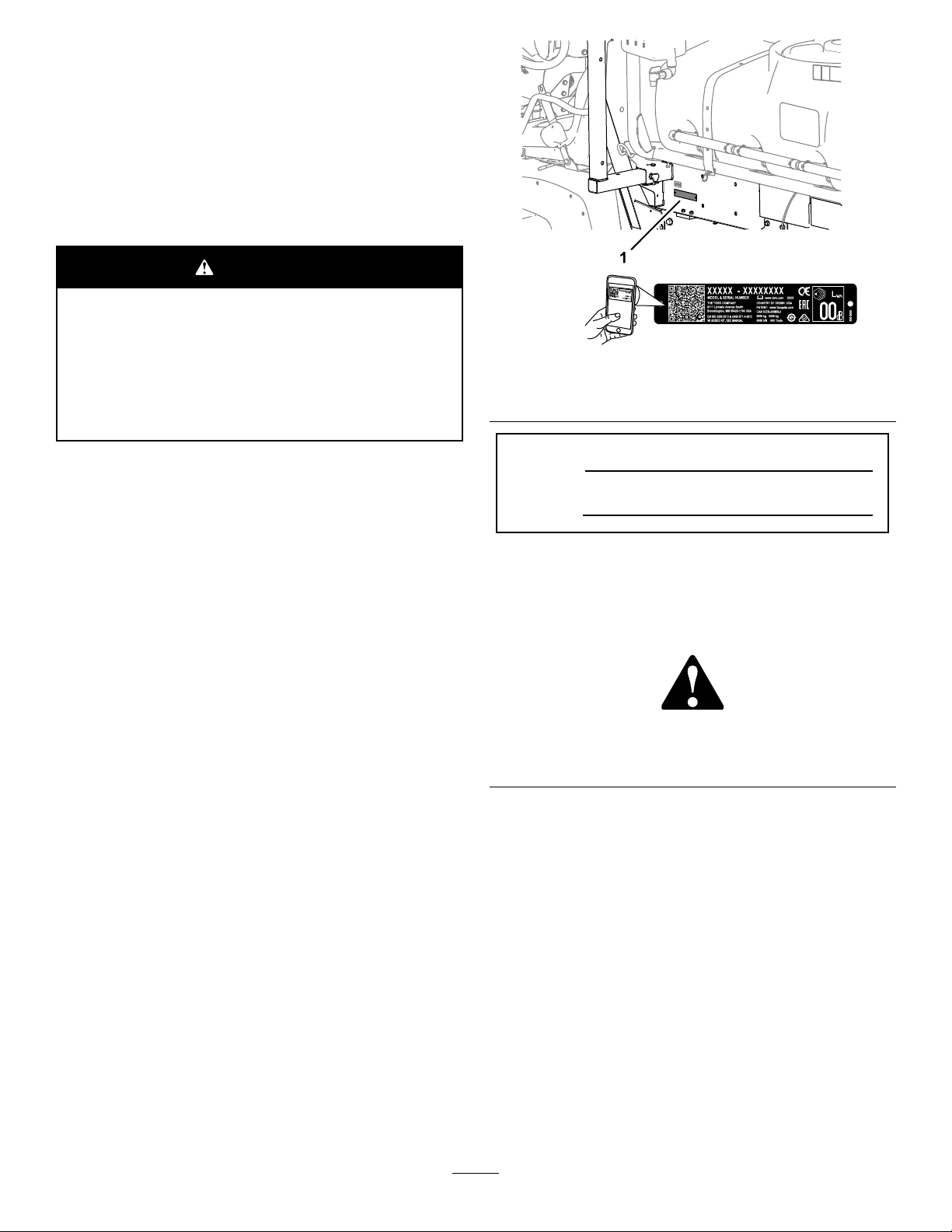

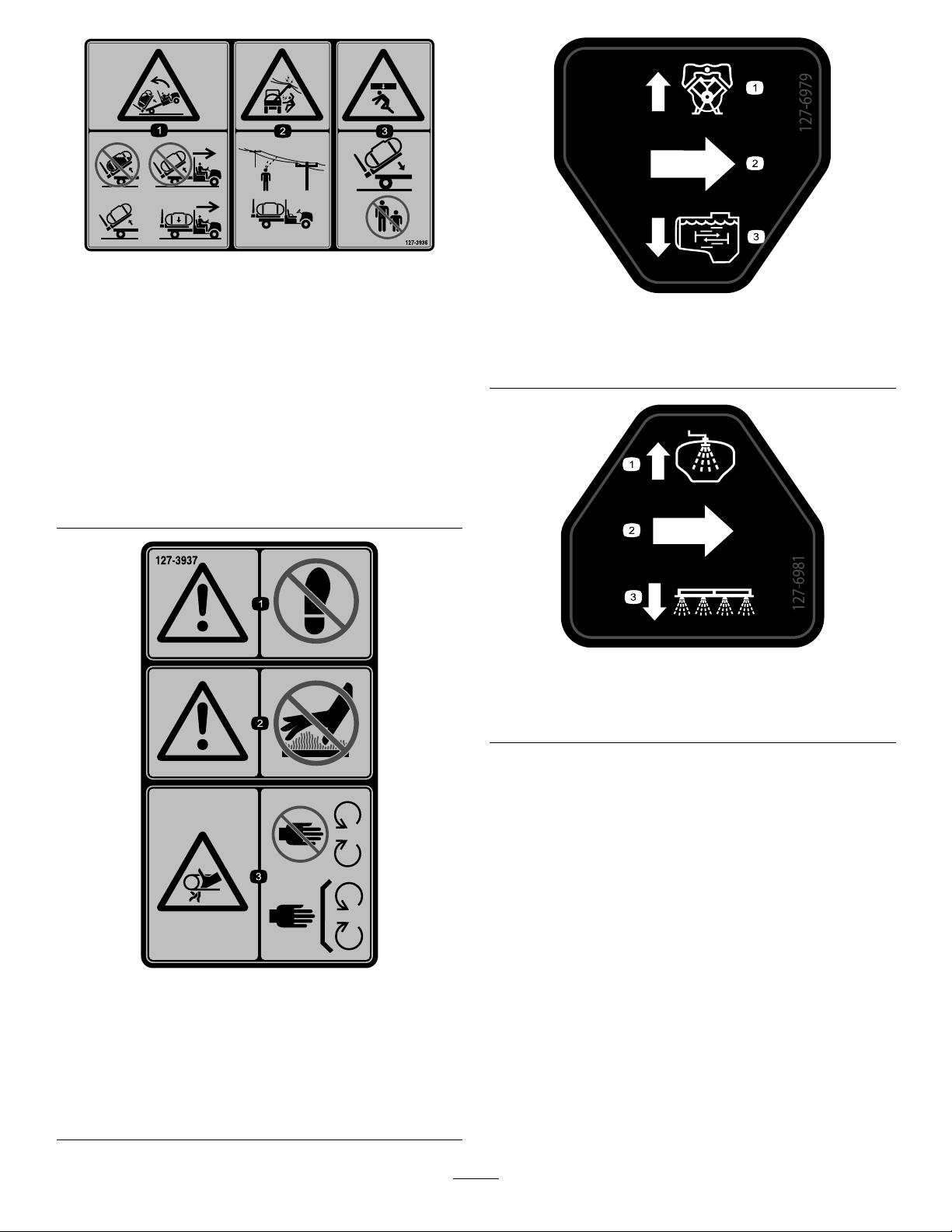

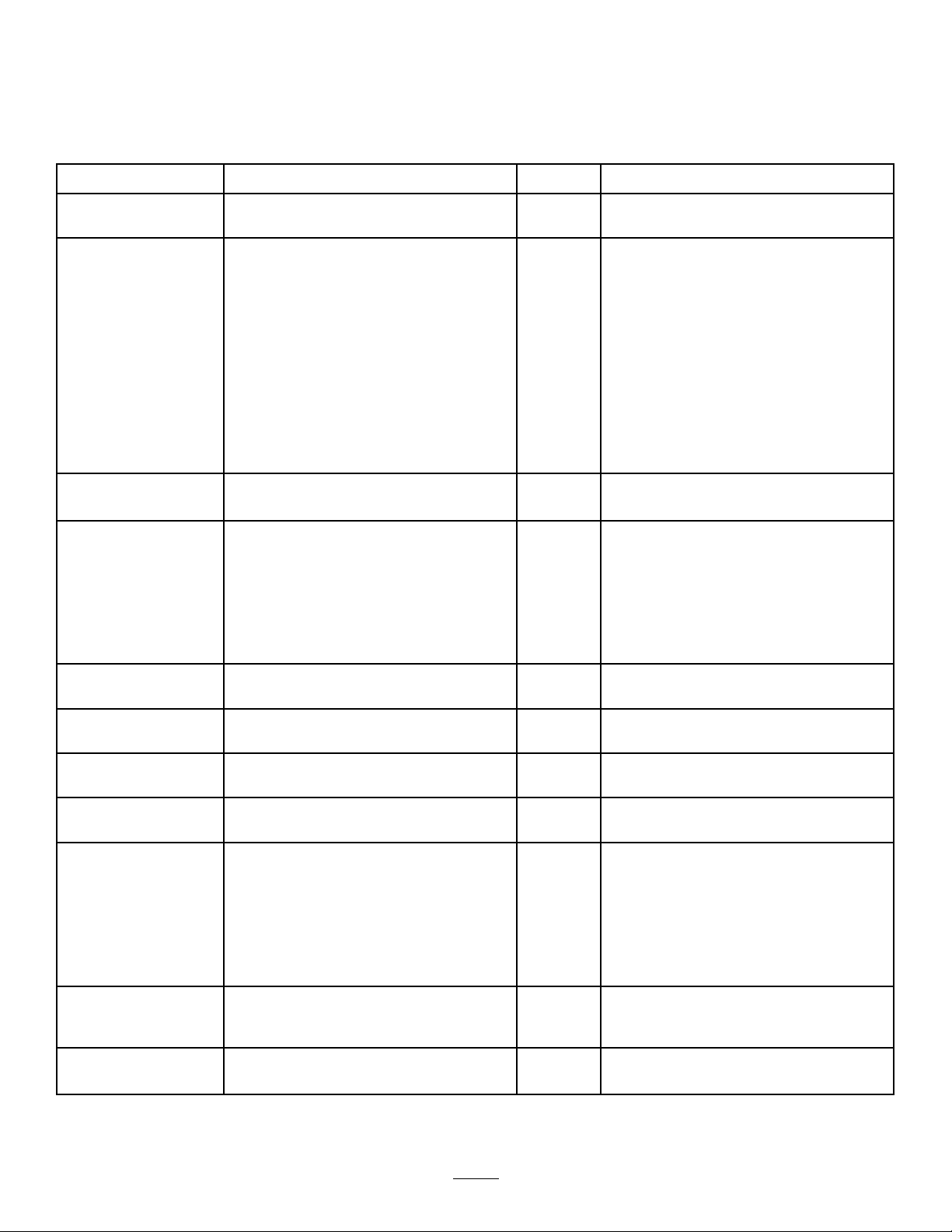

SafetyandInstructionalDecals..........................5

Setup........................................................................9

1RemovingtheExistingBed.............................11

2PreparingtoInstalltheT ankSkid...................12

3InstallingtheHold-DownBracketsforthe

TankSkid......................................................13

4InstallingtheTankSkid..................................13

5AssemblingtheDrainValve...........................15

6DisconnectingtheBattery..............................16

7ConnectingtheSpeedSensor

Harness........................................................17

8CouplingtheSprayerPump...........................18

9InstallingtheControlConsoletothe

Machine........................................................18

10InstallingtheElectricalHarnessesforthe

Sprayer.........................................................19

11InstallingtheSprayerFuseBlock.................20

12ConnectingtheSprayerHarnesstothe

Battery..........................................................22

13LoweringtheTankSkid................................25

14InstallingtheCenterBoomSection...............26

15InstallingtheLeftandRightBoom

Section..........................................................27

16InstallingtheBoomHoses............................29

17InstallingtheNozzles...................................31

18InstallingtheFreshwaterT ank......................31

19InstallingtheAnti-SiphonFill

Receptacle....................................................33

20StoringtheJackStands(Optional)...............34

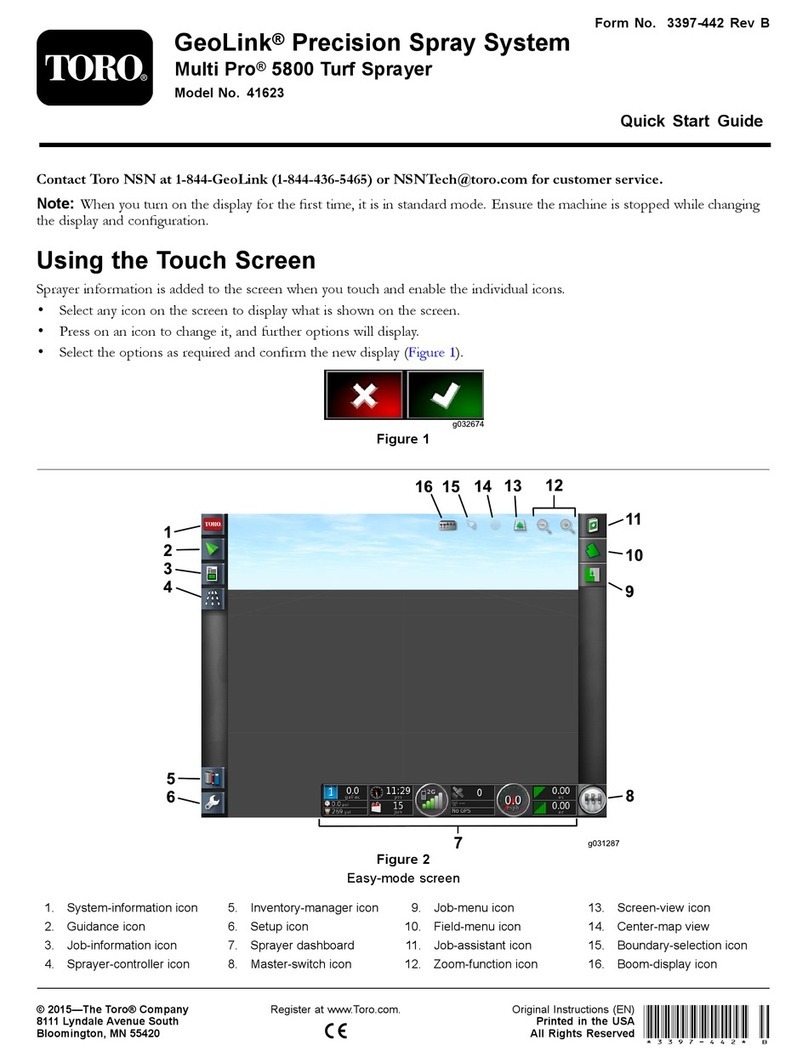

ProductOverview...................................................35

Controls...........................................................35

Specications..................................................38

Attachments/Accessories.................................38

BeforeOperation.................................................38

BeforeOperationSafety...................................38

UsingtheInfoCenter.........................................39

PerformingPre-StartingChecks.......................49

PreparingtheSprayer.......................................49

CalibratingtheSprayer.....................................53

CalibratingtheSprayerSpeed..........................54

CalibratingtheSection-BypassValves..............55

AdjustingtheAgitationandMasterBypass

Valves...........................................................56

LocatingtheSprayPump..................................57

DuringOperation.................................................57

DuringOperationSafety...................................57

OperatingtheSprayer......................................59

Spraying...........................................................59

TurfCarePrecautionswhileOperatingin

StationaryModes..........................................60

PositioningtheSpraySections.........................60

SprayingTips....................................................61

UncloggingaNozzle.........................................62

AfterOperation....................................................62

AfterOperationSafety......................................62

CleaningtheSprayerSystem...........................62

CleaningtheSuctionFilter................................63

CleaningthePressureFilter.............................64

CleaningtheNozzleFilter.................................65

ConditioningtheSpraySystem.........................65

TransportingorT owingtheMachine.................66

Maintenance...........................................................67

MaintenanceSafety..........................................67

RecommendedMaintenanceSchedule(s)...........68

DailyMaintenanceChecklist.............................69

NotationforAreasofConcern...........................69

Pre-MaintenanceProcedures..............................70

AccessingtheMachine.....................................70

Lubrication..........................................................71

GreasingtheSprayerPump.............................71

GreasingtheBoomHinges...............................72

ElectricalSystemMaintenance...........................72

ElectricalSystemSafety...................................72

ReplacingtheFuses.........................................72

SpraySystemMaintenance.................................73

InspectingtheHoses........................................73

ChangingtheSuctionFilter...............................73

ChangingthePressureFilter............................73

ChangingtheNozzleFilter................................74

InspectingtheSprayerPump............................75

InspectingtheNylonPivotBushings.................75

AdjustingtheBoomstoLevel............................76

Cleaning..............................................................77

CleaningtheFlowmeter...................................77

CleaningtheSprayerValves.............................77

Storage...................................................................88

StorageSafety..................................................88

PreparingtheMachineforStorage...................88

Long-TermStorage...........................................89

PreparingtheMachineforService....................90

RemovingtheSprayerandT ankSkid...............90

Troubleshooting......................................................93

Schematics.............................................................94

3