2

AC22

Assembly and operating instructions

Safety

• For all installations of electrically heated products

should a residual current circuit breaker 300 mA for

re protection be used.

• Keep the areas around the air intake and exhaust gril-

les free from possible obstructions!

• CAUTION! During operation the surfaces of the unit

can be hot!

• e unit must not be fully or partially covered with

clothing, or similar materials, as overheating can result

in a re risk! (E)

• e appliance can be used by children, aged from 8

years and above, and by persons (children included)

with reduced physical, sensory, or mental capabilities,

or lack of experience and knowledge, if they have been

given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards

involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made

by children without supervision.

Children, of less than 3 years of age, should be kept

away unless continuously supervised.

Children, aged from 3 years and less than 8 years, shall

only switch on/o the appliance, provided that it has

been placed or installed in its intended normal opera-

ting position and they have been giving supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved. Children,

aged from 3 years and less than 8 years, shall not plug

in, regulate and clean the appliance or perform user

maintenance.

General instructions

Read these instructions carefully before installation and

use. Keep this manual for future reference.

e product may only be used as set out in the assembly

and operating instructions. e guarantee is only valid

if the product is used in the manner intended and in ac-

cordance with the instructions.

Application area

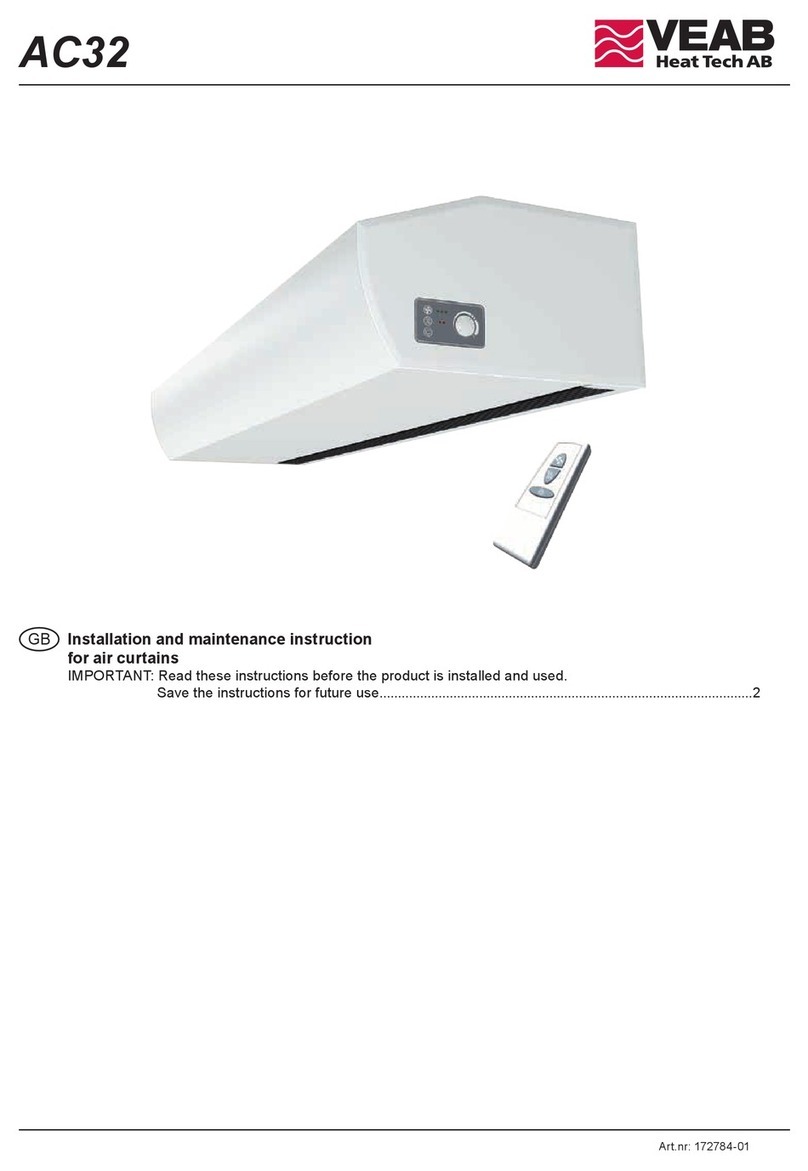

e AC22 air curtain unit is supplied without heating,

with electrical heating or hot water heating.

e AC22 is a compact air curtain, suitable for most small

entrances up to 2.2 metres in height. e air curtain has

an integrated control system and can be remotely control-

led.

Protection class for units with electrical heating: IP20.

Protection class for units without heating and units with

water heating: IP21.

Operation

Air is drawn in at the top of the unit and blown out

downwards so that it shields the door opening and mi-

nimizes heat loss. To achieve the optimum curtain eect

the unit must extend the full width of the door opening.

e grille for directing exhaust air is adjustable and is

normally angled outwards to achieve the best protection

against incoming cold air.

e eciency of the air curtain depends on the air tem-

perature, pressure dierences across the doorway and any

wind pressure.

NOTE! Negative pressure in the building considerably

reduces the eciency of the air curtain. e ventilation

should therefore be balanced.

Mounting

e air curtain unit is installed horizontally with the

supply air grille facing downwards as close to the door

as possible. Minimum distance from outlet to oor for

electrically heated units is 1800 mm. For other minimum

distances, see g. 4.

Mounting with wall brackets (g. 6)

1. Mount the brackets on the wall, see g.6A and

dimension drawing g.1. If the wall is uneven

the brackets must be compensated for this.

2. Hook on the unit at the lower edge of the brackets.

(Fig.6B-C)

3. Bend the top of the console over the unit

and slide the units screws along the rail into

the slots on the consoles, (Fig.6D). When the

bracket is bent once, it must be replaced if bent

back more than 45 °.

4. Lock the nuts against the brackets. (Fig.6E)