CONTENT

OPERATION INSTRUCTIONS ............................................................................................................................ I

CAUTIONS!.......................................................................................................................................................... I

AFTERSALES-SERVICES .................................................................................................................................. I

CONTENT ............................................................................................................................................................ I

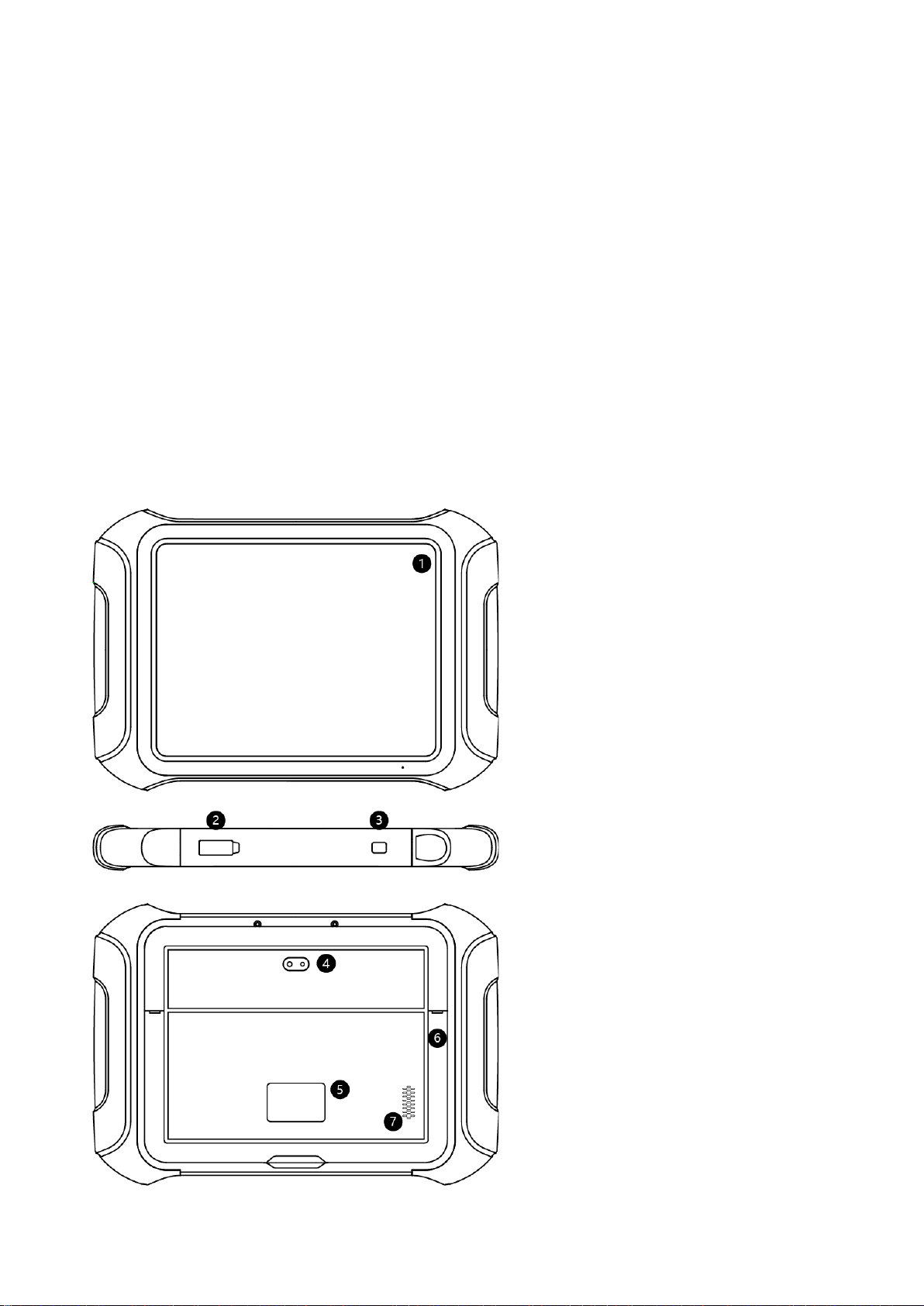

1. GENERAL INTRODUCTION..................................................................................................................... 3

Main Units........................................................................................................................................................................3

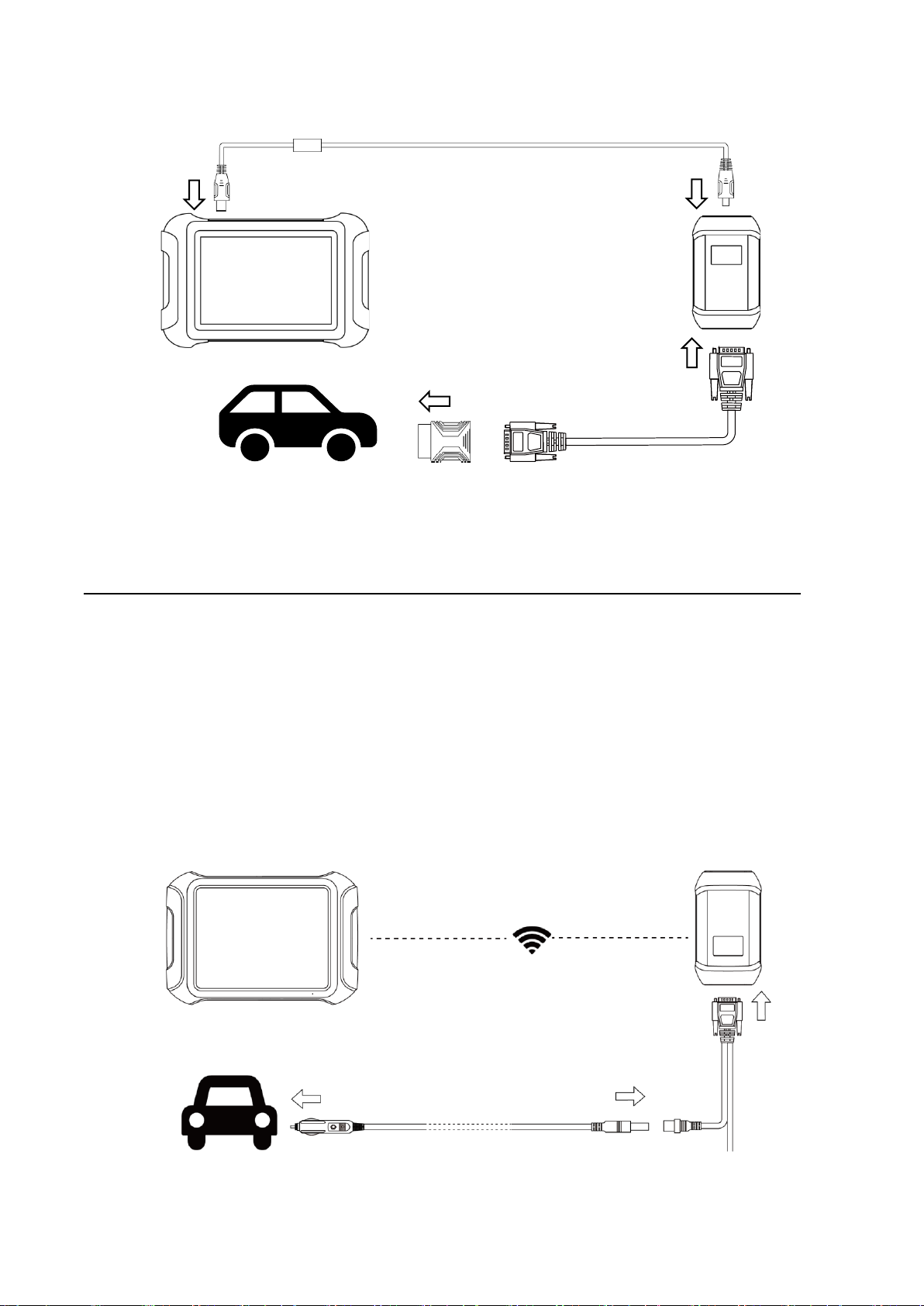

Vehicle Connection..........................................................................................................................................................5

WIFI connection ..................................................................................................................................................................................... 5

Wired Connection ................................................................................................................................................................................. 5

Self-test..................................................................................................................................................................................................... 6

2. DIAGNOSTIC ............................................................................................................................................ 7

Beginning Diagnostic Testing ..........................................................................................................................................8

Vehicle Selection.................................................................................................................................................................................... 8

Diagnosis functions............................................................................................................................................................................... 9

ECU Coding & Programming..........................................................................................................................................................16

3. BATTERY PACK DETECTION............................................................................................................... 18

4. CAN INSPECTION .................................................................................................................................. 18

5. COMPONENT TEST ............................................................................................................................... 20

Compressor detection....................................................................................................................................................20

OBC detection ...............................................................................................................................................................20

Component test-48V motor detection ............................................................................................................................21

DCDC detection.............................................................................................................................................................21

6. SPECIAL FUNCTIONS ........................................................................................................................... 21

ABS BLEEDING.............................................................................................................................................................21

OIL RESET....................................................................................................................................................................24