5

xTool D1 Pro xTool D1 Pro

Settings for power and speed, the critical numbers that often vex us-

ers, are set automatically if the user chooses to use materials that have

been tested by xTool engineers, such as 3mm Basswood Plywood,

as shown under the Material eld in FIG. 10. e user can easily

choose to Score, Engrave, or Cut whatever is on the workspace, and

the associated machine settings will change accordingly. is is a sig-

nicant advantage over competing machines.

e optional LightBurn software (https://lightburnsoftware.com/),

available for a free 30-day trial, or at a cost of $60 for permanent use,

provides extensive capabilities, and enables the D1 Pro to realize all

of its potential. LightBurn, available for Mac, PC and Linux, also

supports many more le formats than XCS.

Laser Positioning

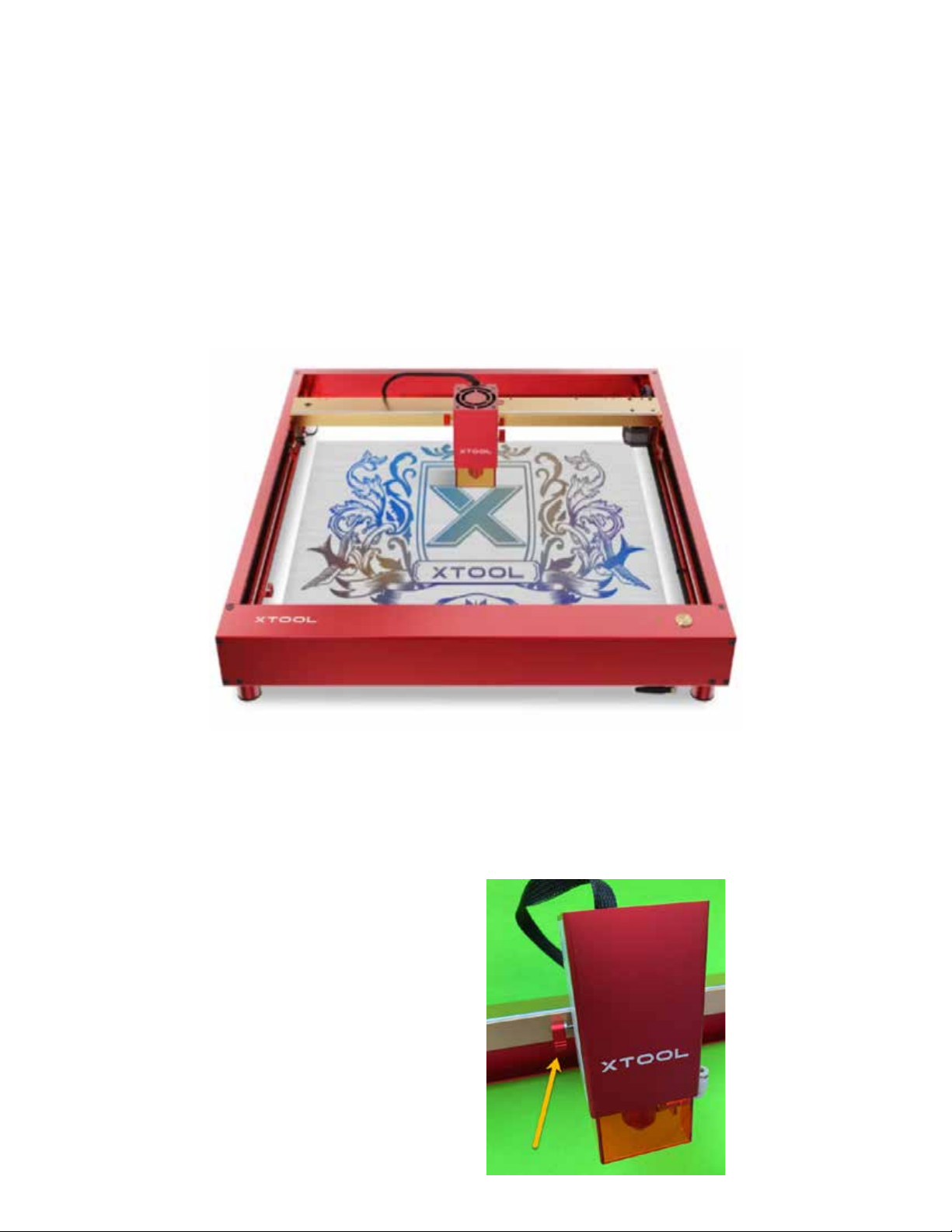

e D1 Pro now includes limit switches that contain the movement

of the laser module within the frame (FIG. 11). is not only stops

the module from hitting the frame rails, but provides more user con-

trol over workpiece placement. Should the laser head reach one of

the frame boundaries it will stop and the limit switch will signal an

alarm. In addition, and perhaps most importantly, the limit switches

enable the use of absolute coordinates, and setting the home posi-

tion, wherein the user can use a laser bed grid system to accurately

line-up workpieces.

e engraving area is 430mm x 390mm (17” x 15.4”), slightly small-

er than that of the original D1 due to the increased size of the 20W

laser module.

FIG. 11. xTool uses an advanced design, long-lasting electronic limit

switch, which is superior to a mechanical roller lever arm.

Air Assist

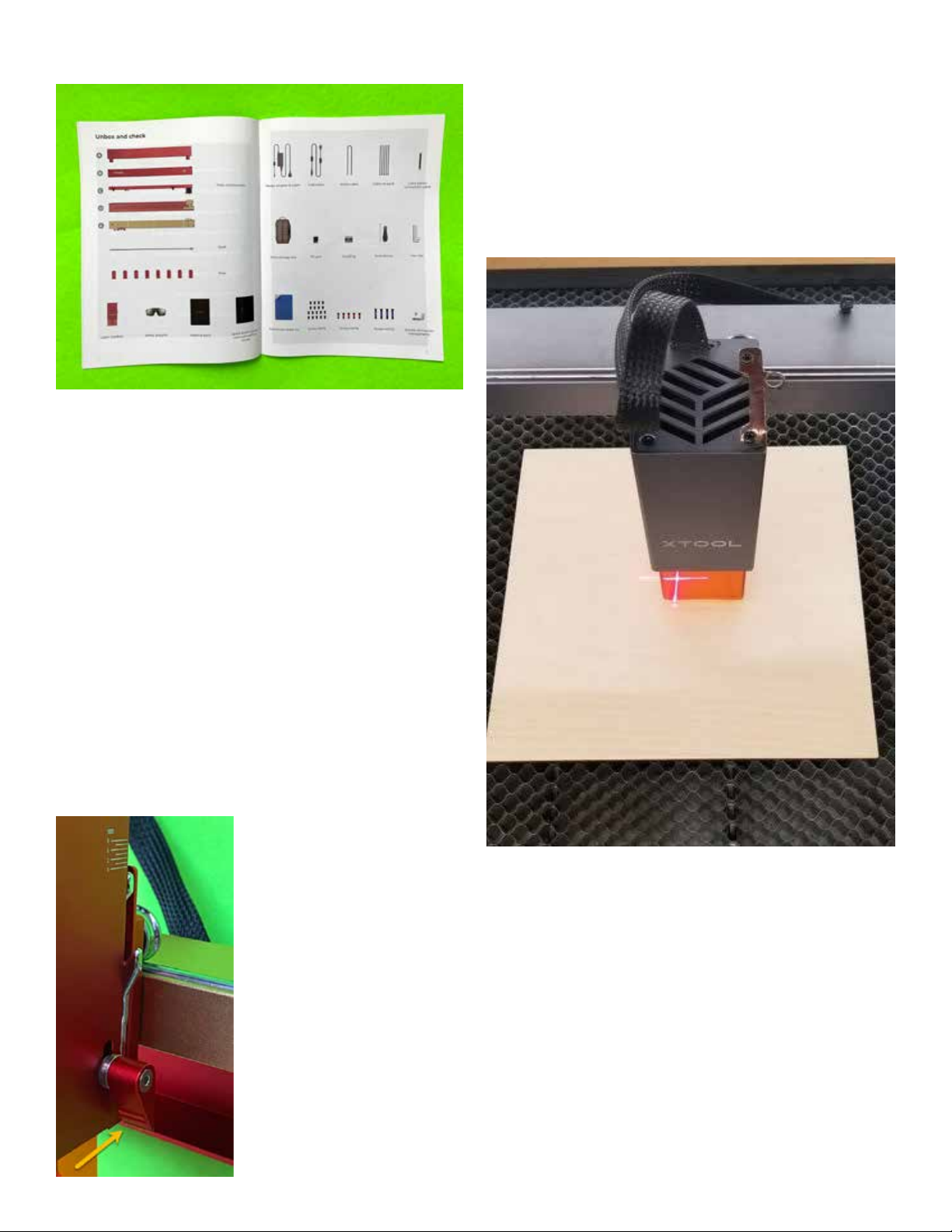

e laser head is now manufactured to be “air assist ready” (FIG.

12). In recognition of the fact that air assist is an essential feature for

laser cutting, providing cleaner nished material surfaces, and not

just an optional add-on, the laser head has been engineered with a

built-in nozzle adaptable to a provided air intake connector. e user

need only connect plastic air feed tubing and a pump. xTool sells an

optional Air Assist Set that provides all of the parts necessary for in-

stallation, although third-party solutions can also be used. e xTool

air pump is distinguished by its quiet operation, which is a signicant

advantage, considering potentially long processing times.

FIG. 12. e supplied air intake connector screws directly into a thread-

ed opening in the laser nozzle.

Air assist not only provides a cleaner cut, but enables deeper and fast-

er cutting. Another advantage of air assist is to protect the surface of

the laser lens and the light shield, blowing away smoke and air-borne

debris. A cleaner lens performs more eciently and extends the life

of the laser head, and a cleaner light shield makes it easier to see the

laser activity.

Rotary

e optional RA2 Pro Rotary Attachment, considered the most ver-

satile rotary device of its kind, enables engraving on a wide variety of

cylindrical and round objects of various circumferences and lengths

(FIG. 13). e unique design provides unprecedented exibility in

grasping and holding objects, with friction or clamp-style jaws, for

precision engraving.