Firmware Information.....................................................................................................................................................34

About .............................................................................................................................................................................34

7. REPORT.................................................................................................................................................. 34

Report............................................................................................................................................................................35

Replay............................................................................................................................................................................36

File Manager..................................................................................................................................................................37

8. UPDATE & FACTORY RESET............................................................................................................... 37

Update...........................................................................................................................................................................37

Factory Reset ................................................................................................................................................................38

9. FAQ.......................................................................................................................................................... 39

Q1: Failed to generate Diagnostic report.......................................................................................................................39

Q2: How to print a Diagnostic report..............................................................................................................................40

Q3: Failed to extract files...............................................................................................................................................40

Q4: Mailbox supported...................................................................................................................................................40

Q5: How to make an appointment for remote support ...................................................................................................40

Q6: How to generate and upload diagnostic log files.....................................................................................................40

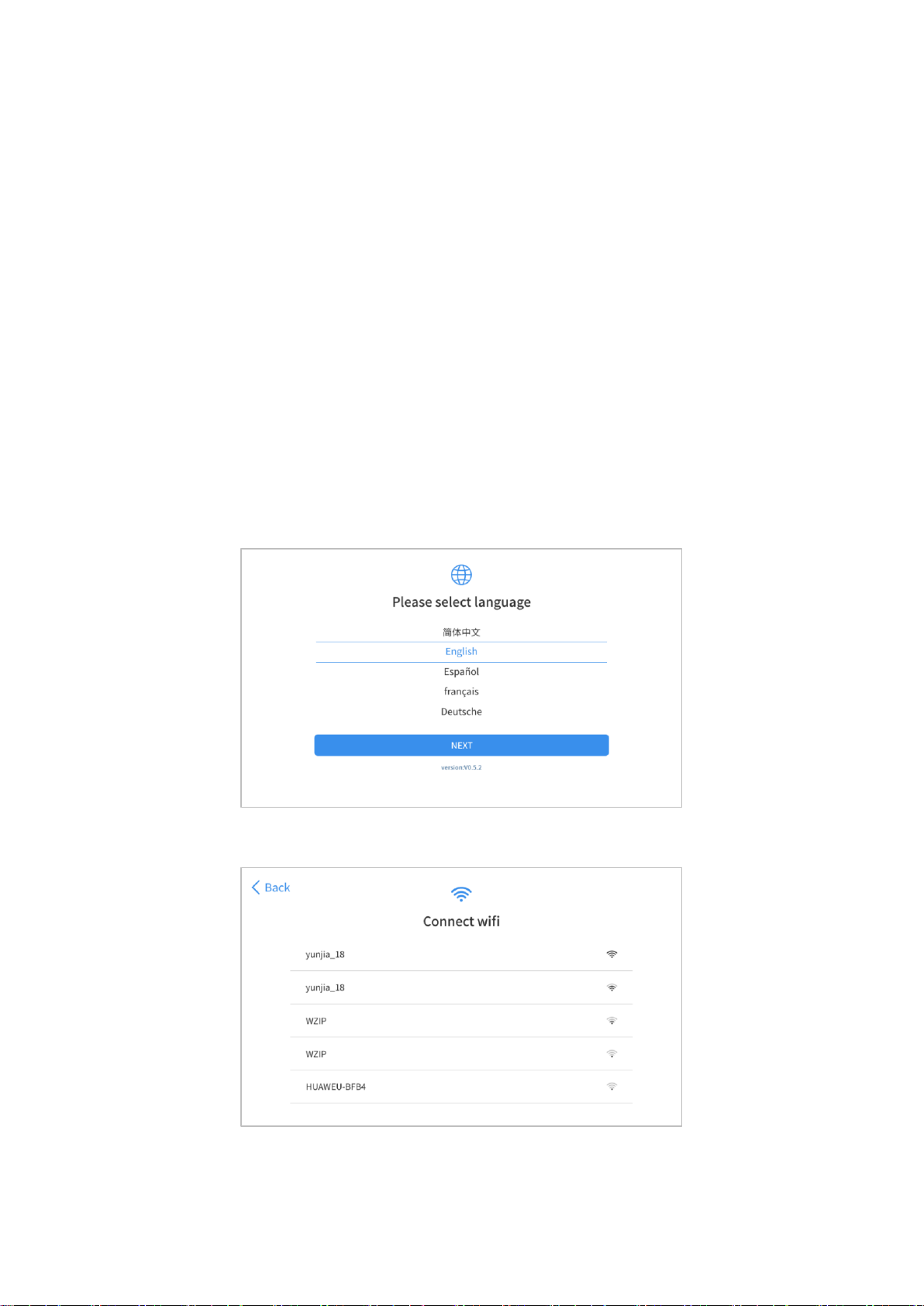

Q7: How to switch language..........................................................................................................................................40

Q8: Failed to diagnose vehicle.......................................................................................................................................40

Q9: Failed to activate or register....................................................................................................................................41

Q10: Failed to turn on when charging............................................................................................................................41

Q11: Failed to open the Diagnostic app.........................................................................................................................41

Q12: Can’t receive the email after sharing the diagnostic report ...................................................................................41

10. WARRANTY & SERVICES..................................................................................................................... 41

11. REMOTE ASSISTANCE ......................................................................................................................... 42

12. APPENDIX............................................................................................................................................... 43

Trademarks....................................................................................................................................................................43

Copyright .......................................................................................................................................................................43

Button Description..........................................................................................................................................................43