PS90 Diagnosis System

Contents

CHAPTERⅠAbout PS90...............................................................................................1

1. Appearance ................................................................................................................1

1.1. Front View...............................................................................................................1

1.2. Back View................................................................................................................1

2. Layout of PS90 Tablet.................................................................................................2

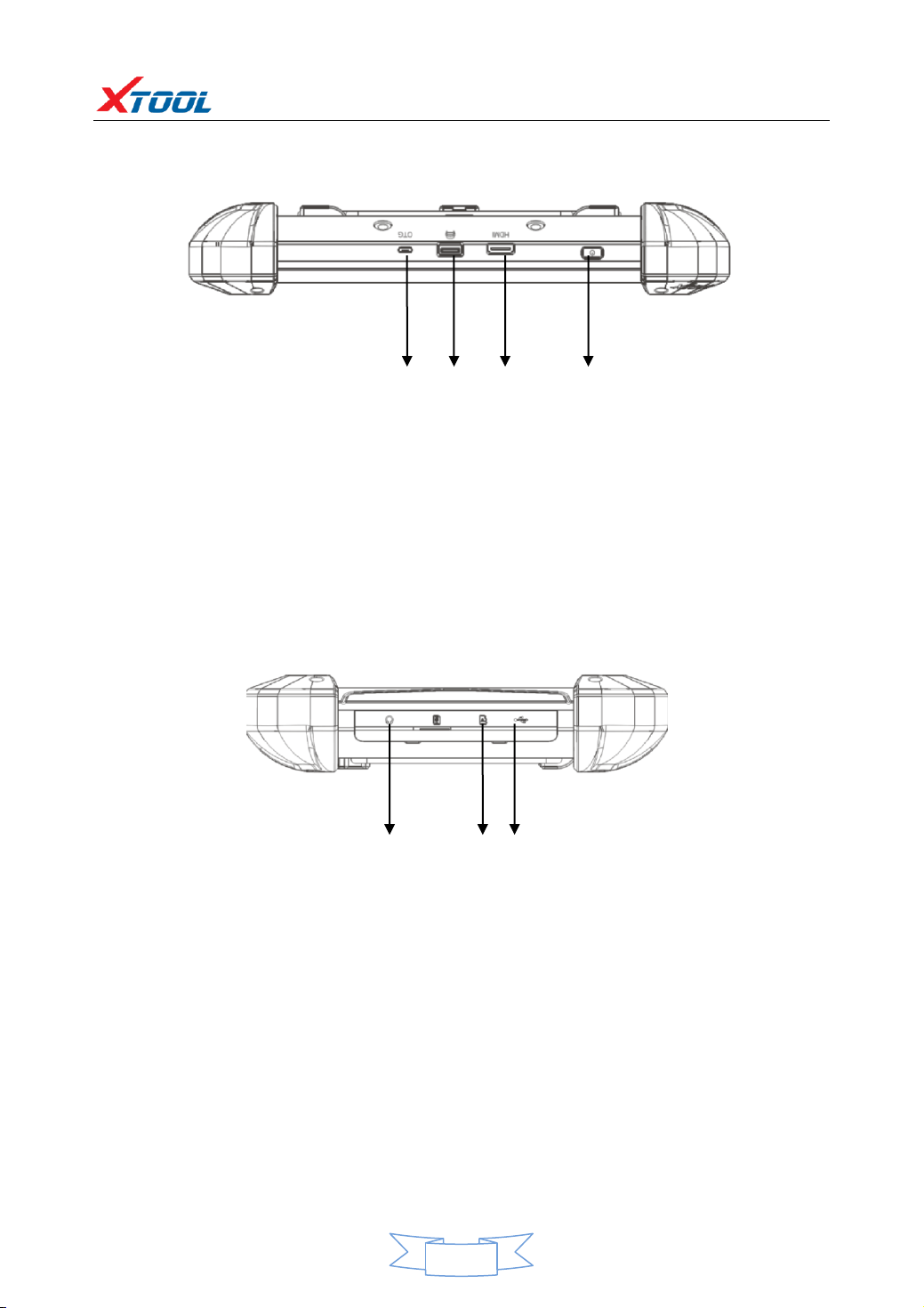

2.1. Top View of PS90 Tablet..........................................................................................2

2.2. Side View of PS90 Tablet.........................................................................................2

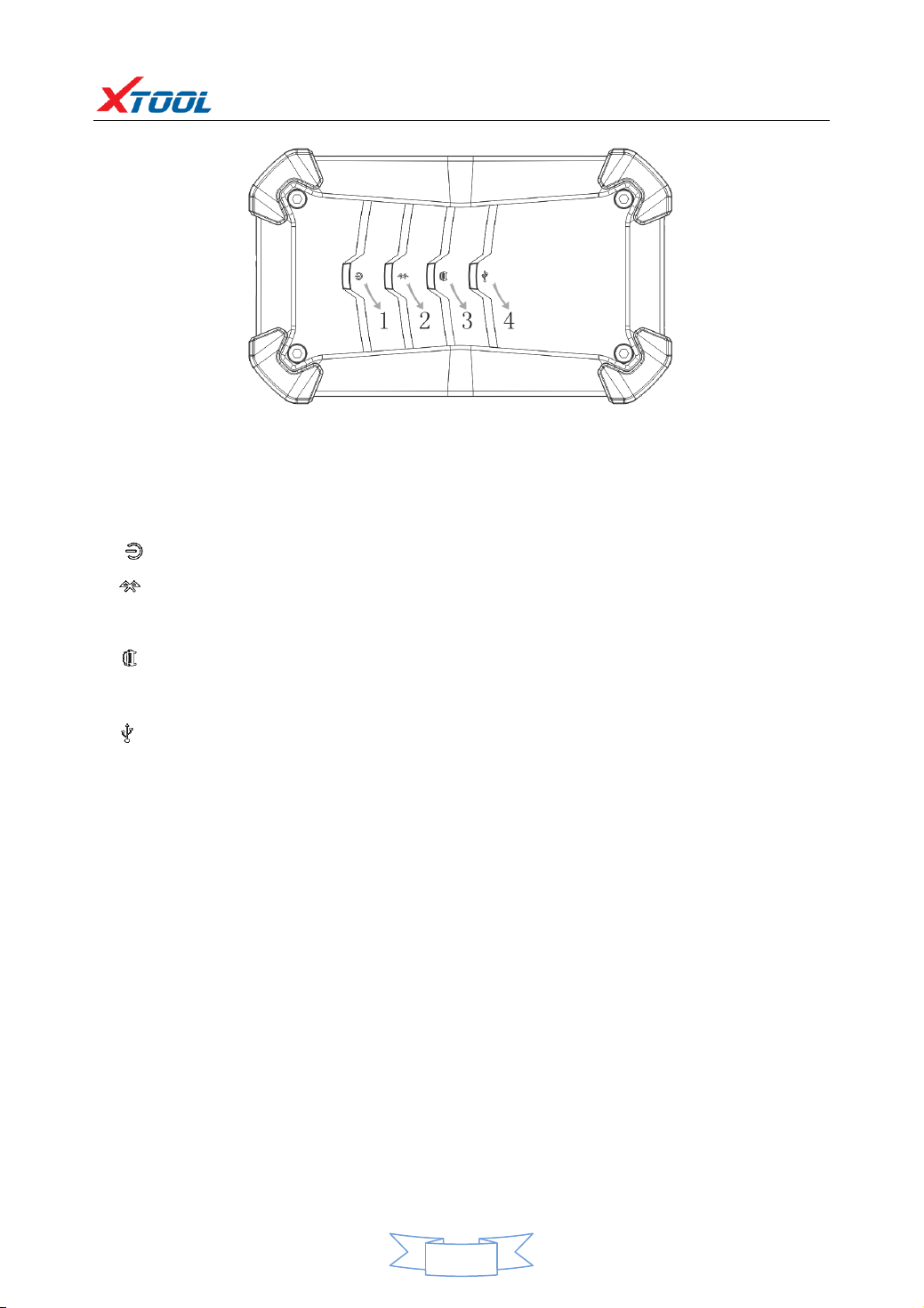

3. Layout of VCI Box .......................................................................................................2

4. PS90 Technical Parameters.........................................................................................3

CHAPTERⅡHow to Use the PS90 Diagnostic Computer............................................4

1. PS90 Activation ..........................................................................................................4

2. PS90 Main Interface and Functional Buttons Descriptions .......................................4

2.1. Main Interface.........................................................................................................4

2.2. Sub-menus and Function Buttons...........................................................................5

2.3. Toolbar Function Buttons........................................................................................5

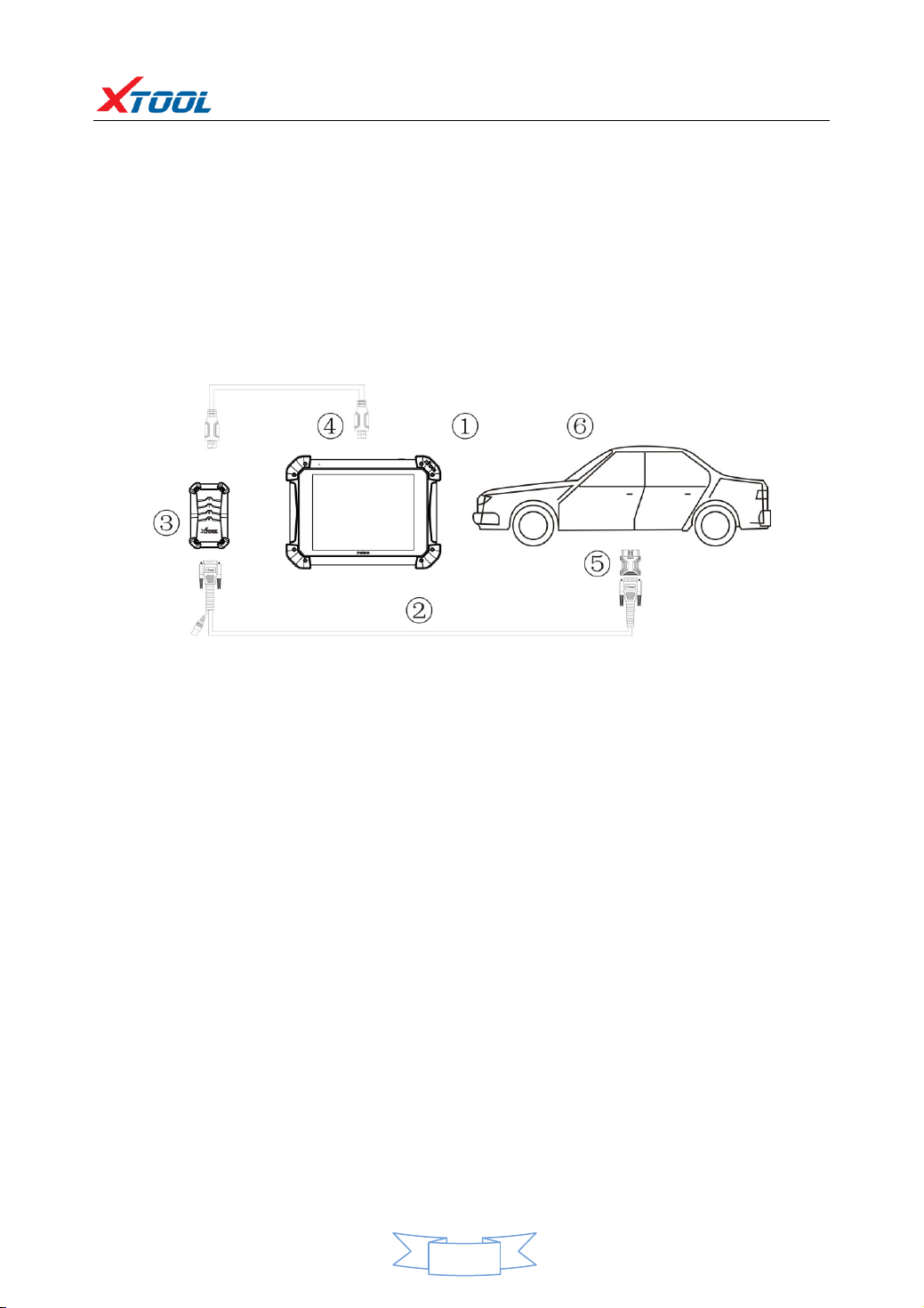

3. Vehicle Connection Diagnosis ....................................................................................6

3.1. Vehicle Connection Test..........................................................................................6

3.2. Precautions Before Use...........................................................................................7

4. Diagnosis ....................................................................................................................7

4.1. Menu Options .........................................................................................................7

4.2. Test Functions .........................................................................................................8

4.3. Read ECU...............................................................................................................10

4.4. Read DTCs..............................................................................................................10

4.5. Clear DTCs .............................................................................................................11

4.6. Read Live Data.......................................................................................................12

4.7. Special Function....................................................................................................15

4.8. Actuation/Active Components Test ......................................................................15

5. Setting ......................................................................................................................16

6. Diagnostic Report.....................................................................................................19

6.1. PDF Files..............................................................................................................200

6.2. Pictures................................................................................................................211

6.3. Data Replay .........................................................................................................211

7. UPDATE.....................................................................................................................22

8. Xtool Cloud System(English version is coming soon).........................................22

9. Remote Diagnosis.....................................................................................................22

CHAPTER ⅢExamples of Diagnostic Link Connector Locations..............................23

1. Diagnostic Link Connectors Locations of Various Vehicle Models...........................23

2. Location Diagram of Vehicle Diagnostic Link Connectors........................................26

3. Diagnostic Link Connectors Terminal Definition and Communication Protocols ....26