2

INDEX

1. Use in compliance with the regulations .............................................................................................. 2

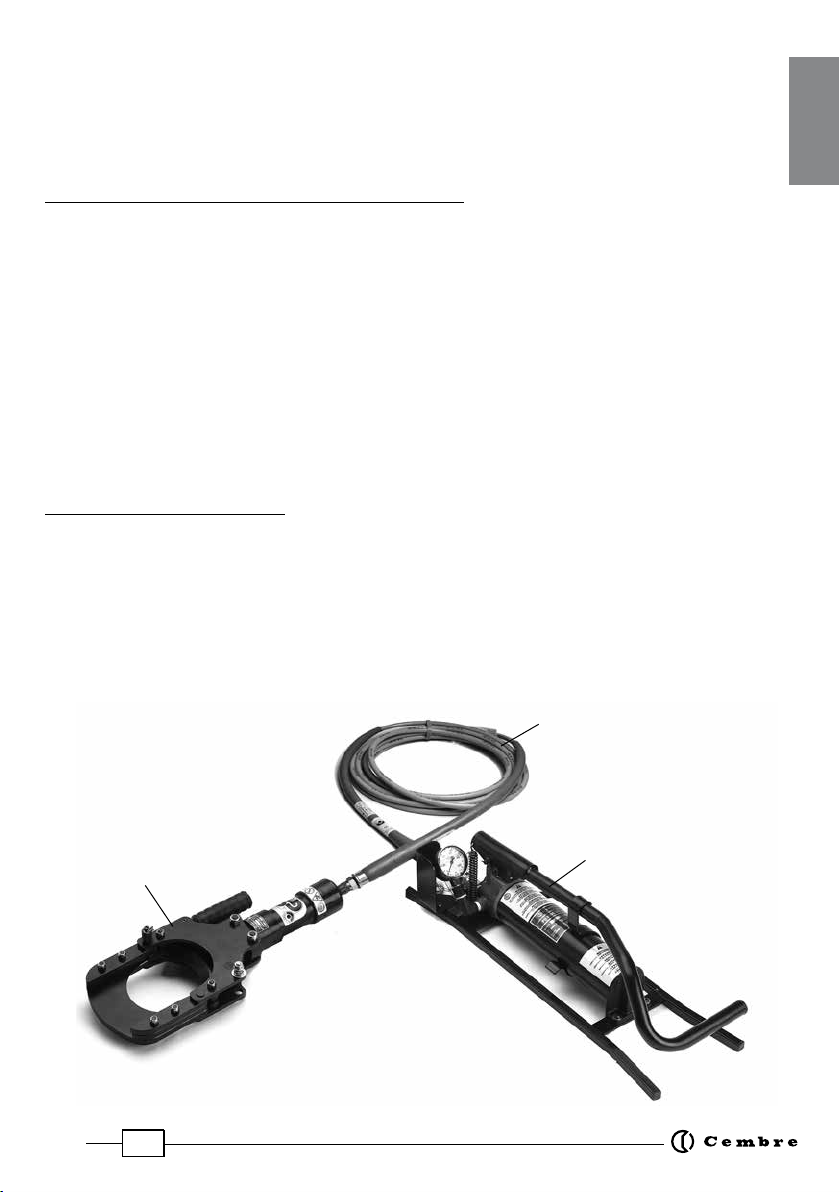

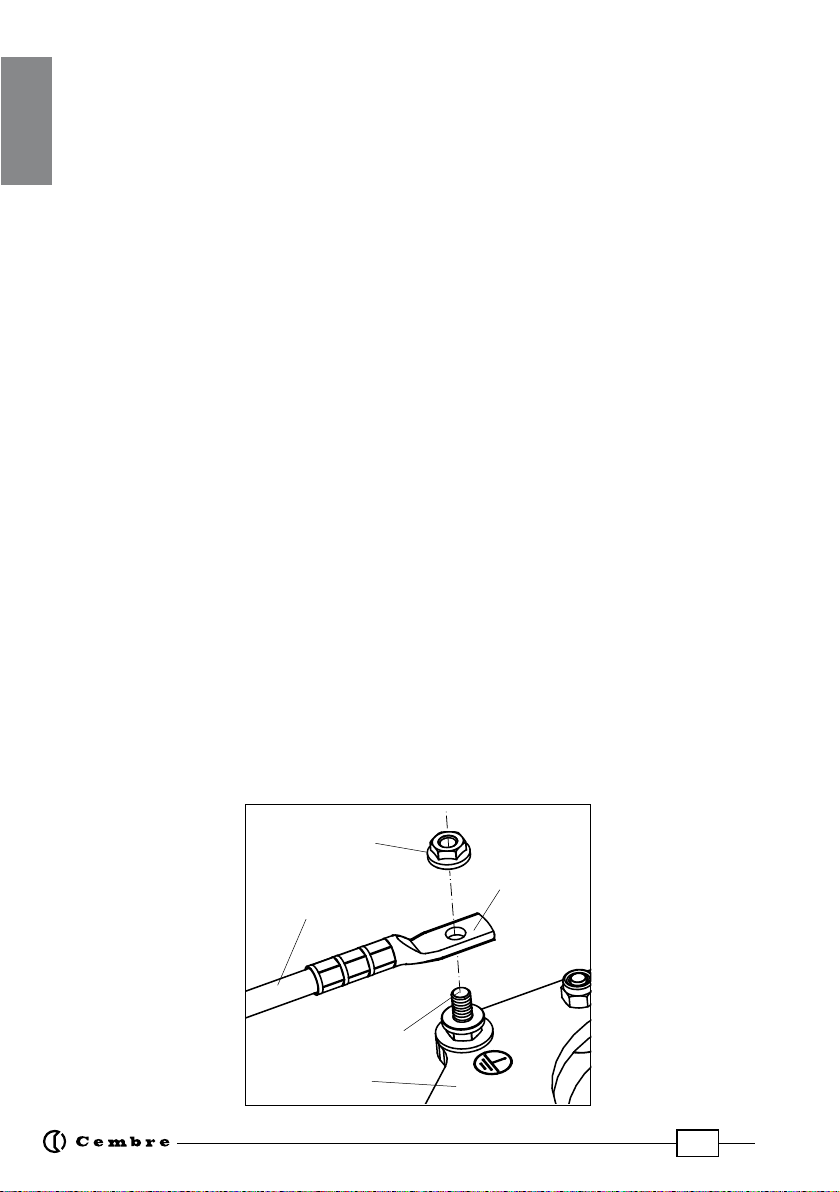

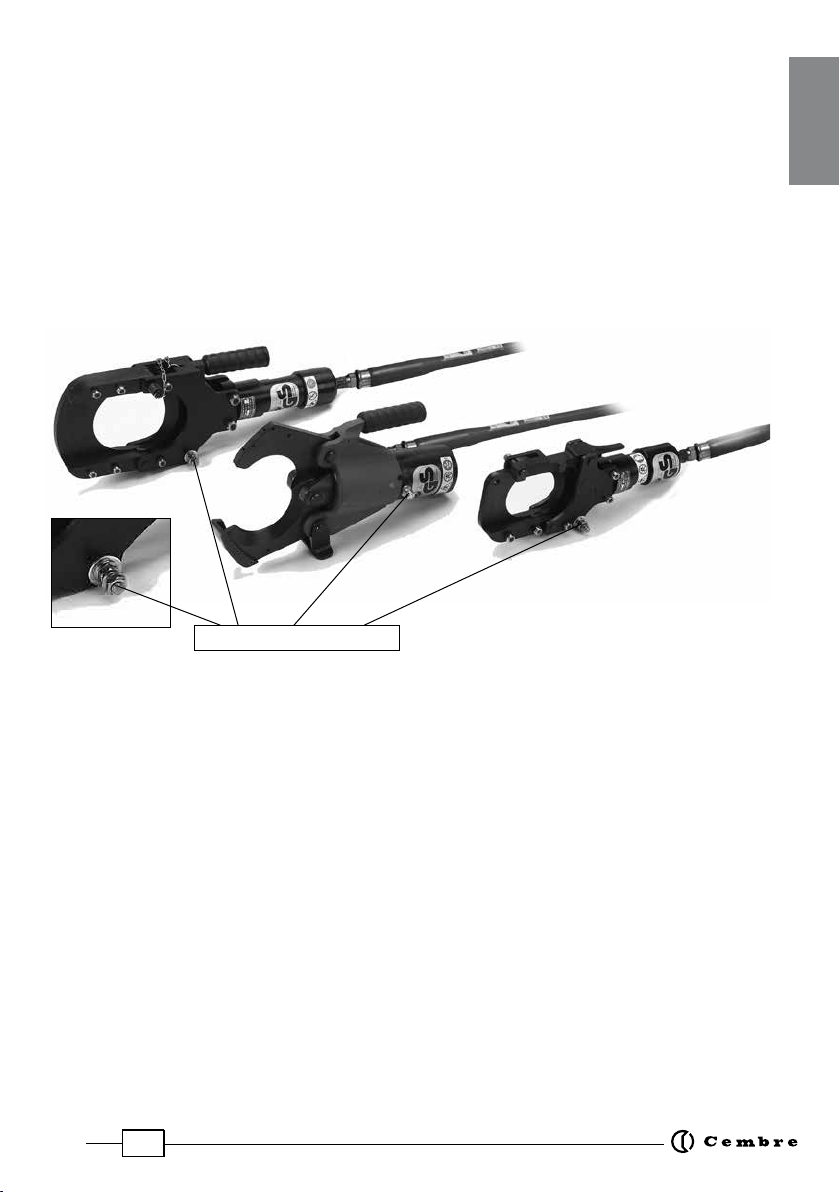

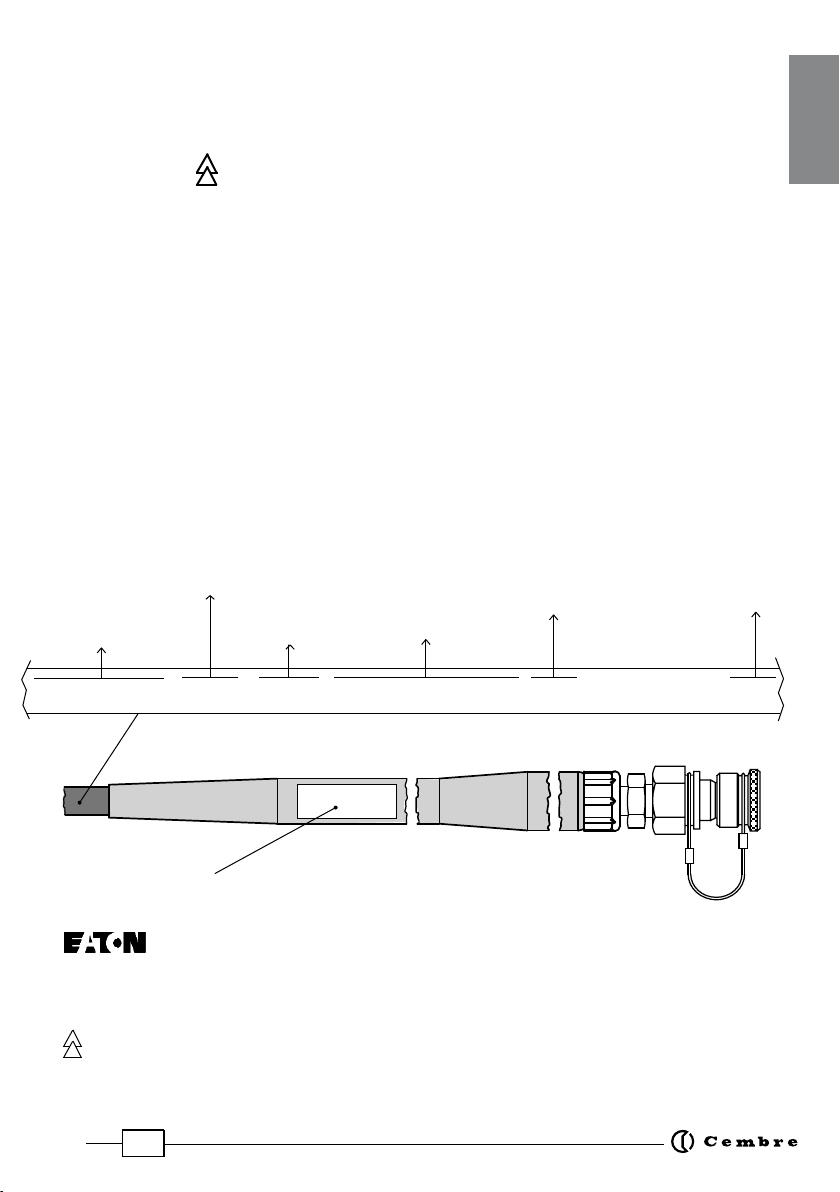

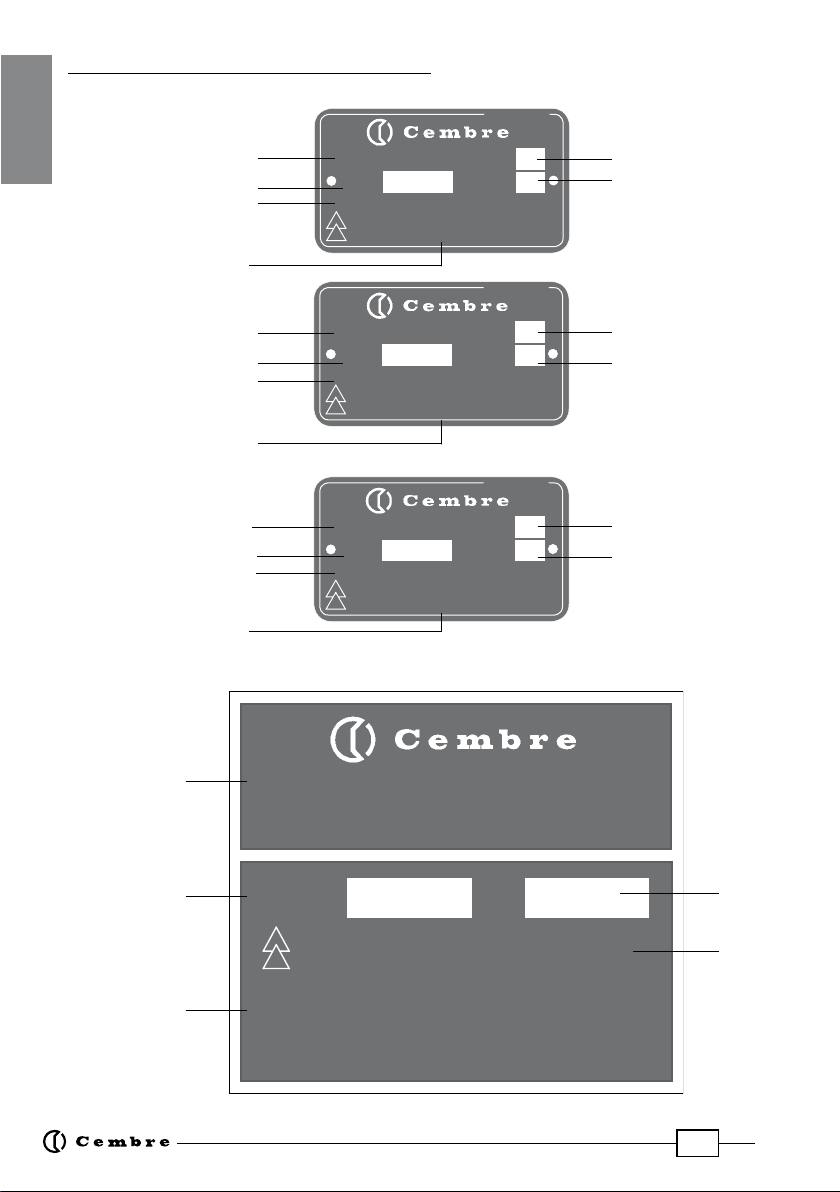

2. Description of device .................................................................................................................................. 2

3. Technical date ................................................................................................................................................ 8

4. Storage and transportation ...................................................................................................................... 9

5. Preliminary phases ....................................................................................................................................... 9

6. Cutting procedure ....................................................................................................................................... 9

7. In case of breakdown ................................................................................................................................ 11

8. Care and maintenance ............................................................................................................................. 13

9. Return to

Cembre

for overhaul ........................................................................................................14

INDEX

1. Emploi conforme aux normes ............................................................................................................... 15

2. Description du dispositif ......................................................................................................................... 15

3. Données techniques ................................................................................................................................. 21

4. Transport ....................................................................................................................................................... 22

5. Phases préliminaires ................................................................................................................................. 22

6. Procédure de coupe .................................................................................................................................. 22

7. Comportement en cas d'anomalie ...................................................................................................... 24

8. Conservation et entretien ....................................................................................................................... 26

9. Envoi en revision à

Cembre

............................................................................................................. 27

INDEX

1. Gebruik volgens de normen .................................................................................................................. 28

2. Beschrijving van de veiligheidsknipset .............................................................................................. 28

3. Technische gegevens ................................................................................................................................ 34

4. Transport ....................................................................................................................................................... 35

5. Inleidende fasen ......................................................................................................................................... 35

6. De knip procedure ..................................................................................................................................... 35

7. Gedrag in geval van onregelmatigheden ......................................................................................... 37

8. Verzorging en onderhoud ...................................................................................................................... 39

9. Teruggave aan

Cembre

voor revisie ............................................................................................. 40

INDICE

1. Utilización conforme con las normas .................................................................................................. 41

2. Descripción del dispositivo .................................................................................................................... 41

3. Datos técnicos ............................................................................................................................................. 47

4. Transporte ..................................................................................................................................................... 48

5. Fases preliminares ...................................................................................................................................... 48

6. Procedimiento de corte ........................................................................................................................... 48

7. Comportamiento en caso de anomalías ............................................................................................ 50

8. Cuidado y mantenimiento ...................................................................................................................... 52

9. Devolución a

Cembre

para revisiones ......................................................................................... 53

INDICE

1. Utilizzo conforme alle norme ................................................................................................................. 54

2. Descrizione del dispositivo ..................................................................................................................... 54

3. Dati tecnici .................................................................................................................................................... 60

4. Trasporto ....................................................................................................................................................... 61

5. Fasi preliminari ............................................................................................................................................ 61

6. Procedura di taglio .................................................................................................................................... 61

7. Comportamento in caso di anomalie ................................................................................................. 63

8. Cura e manutenzione ............................................................................................................................... 65

9. Resa alla

Cembre

per revisione ...................................................................................................... 66

ENGLISH

FRANÇAIS

NEDERLANDS

ESPAÑOL

ITALIANO

Pag. / Blad